Booth 12.1-B69A

#TechnicalWoven #CustomizedTextile #LiquidFiltration #AgroTextile #OutdoorFabrics #HeatSeaLableNonWoven ##BiodegradableFabrics

about us :

Subrenat designs, manufactures and delivers woven and non-woven technical fabrics, to different industry such as Outdoor products, Packaging, Agriculture, filtration, coating…..

Our technical textiles are developed to suit your needs either on technical properties (ex: biocompostable, rotproof, waterproof, flame retardant, UV resistant, heat-sealable, hydrophilic, antistatic…) and services (ex : small quantities deliveries, adjusted delivery time, customised packaging, buffer stock …) thanks to :

– Our 87 years of expertise

– Our internal lab and quality team

– Our R&D team

– Our 200 partners

– Our 15,000m² of warehouses

To follow market trends and our Environmental conviction, we have developed the WePlanet Collaborative program, to offer you a full range of sustainable and environmental textiles products and service

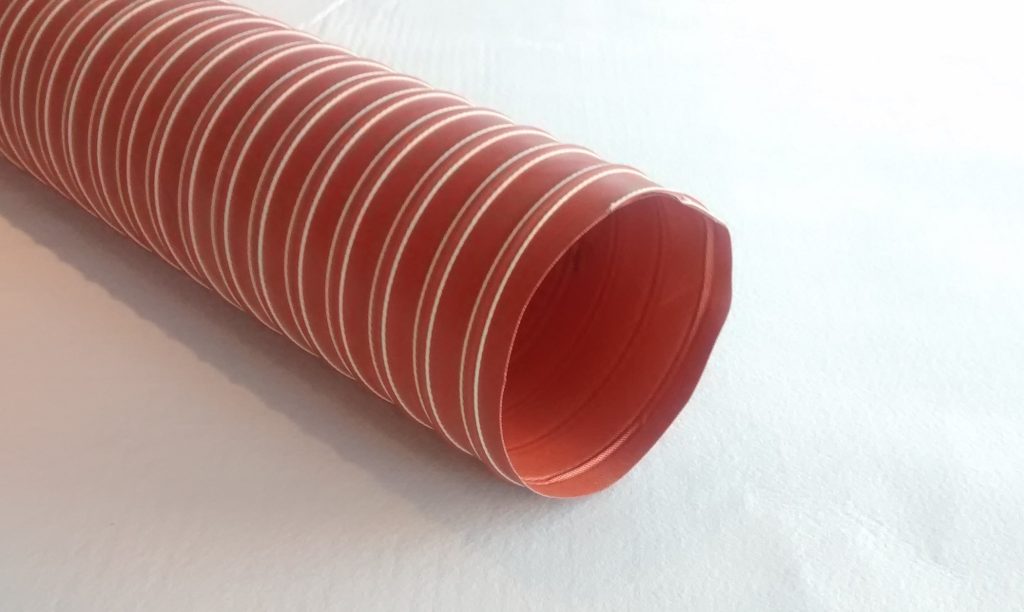

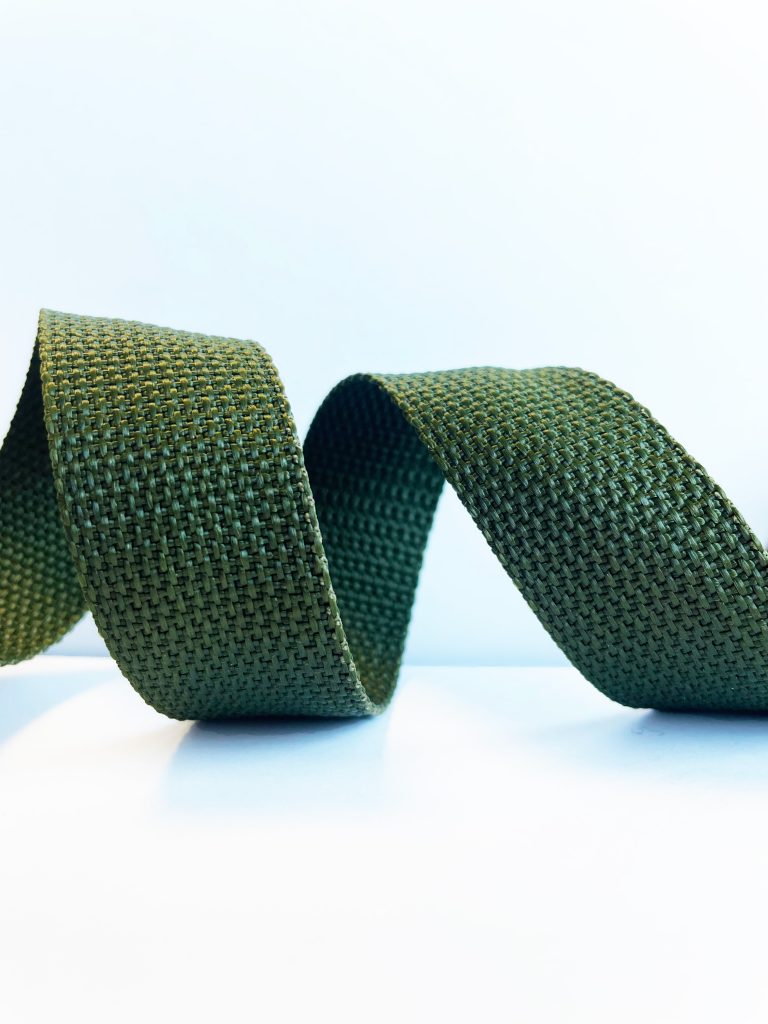

Subrenat provides technical woven solutions which can be waterproof, water repellent, UV resistant, flame retardant, printable…

These solutions are adapted to different applications as outdoor fabrics, printing substrates, coating materials…

Subrenat provides non-woven solutions which can guarantee filtration efficiency, heat sealability, biodegradability. We can customize at your needs…

We make textiles more environmentally friendly for and with our customers. Our new references are eco-designed with all our partners to reduce our social and environmental impact.

CONTACT US

ZA Les peupliers, 91 Rue de l’Épinette Livraison, Rue Michel Raillard – 59420 Mouvaux – France

E-mail : tbt@subrenat.com

Tél : +33 (0)3 20 11 63 63 / +33 (0)6 79 45 86 12

Website : https://www.subrenat.com/en