about us :

SOPARA is a specialist in infrared heating technologies and the design of special machines for various industries.

Our expertise is based on a complete understanding of thermal process, offering innovative and efficient solutions to meet our customers’ most demanding requirements. Whether for drying, curing, forming or other applications, our infrared heating systems offer unrivalled performance, precision and reliability.

SOPARA designs and manufactures special machines and heating elements to suit each customer’s needs. We work in partnership with our customers to understand their requirements and design tailor-made, intelligent solutions.

We serve a wide range of industries, including automotive, aerospace, textile, food, composite and many others. Our commitment to innovation, quality and customer service has enabled us to build strong relationships with our customers around the world.

At SOPARA, our mission is to be our customers’ privileged partner, providing them with high-quality, innovative and reliable infrared heating solutions. We remain at the forefront of technology to meet tomorrow’s challenges and contribute to our customers’ success.

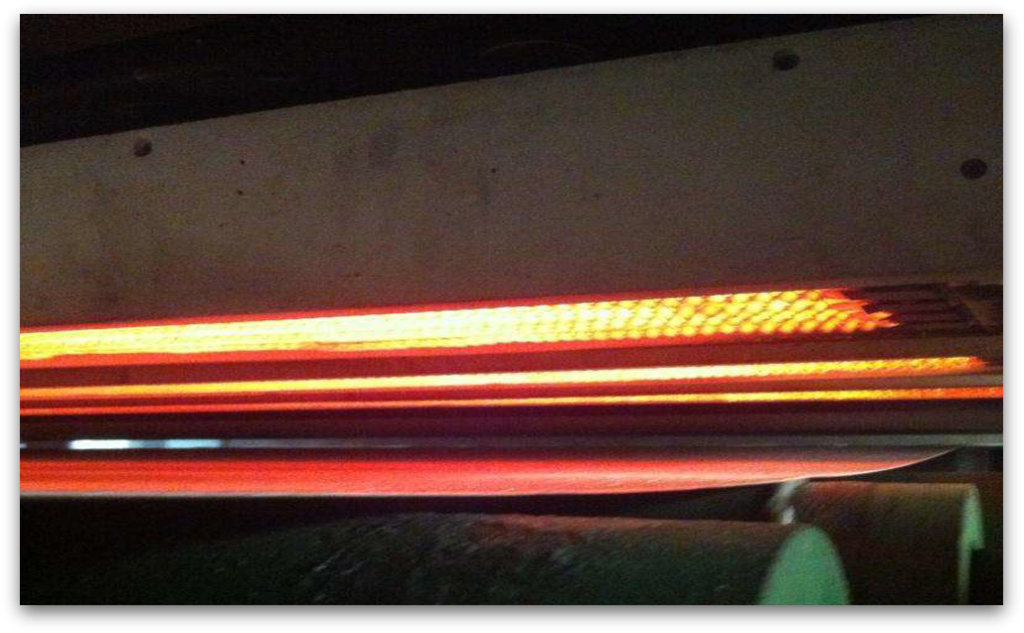

Continuous coating drying : by positioning infrared emitters above and below a continuous product, you can significantly accelerate drying speed. Reduce your process footprint and optimize your space.

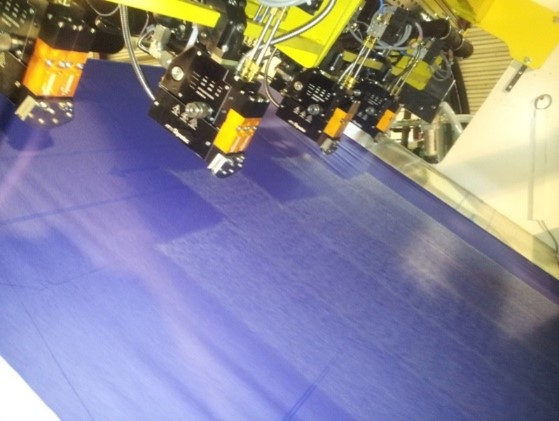

Heated cylinders for textile drying: our heated cylinders are equipped with infrared emitters inside. This gives them all the advantages of infrared heating: low consumption, low maintenance, low inertia, high performance.

Gelling of PVC: our infrared heating systems rapidly achieve homogeneous gelling, while consuming less than a standard hot-air oven.

CONTACT US

27, rue des Bruyères – 69330 PUSIGNAN

Contact : contact@sopara.com

Tél. : +33(0)4 72 81 23 00 / +33(0)4 72 81 23 06

www.sopara.com