about us :

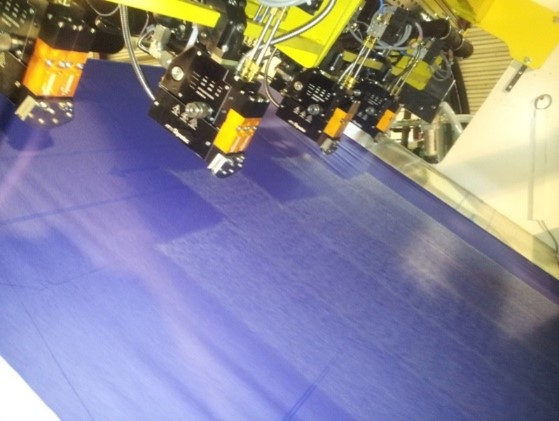

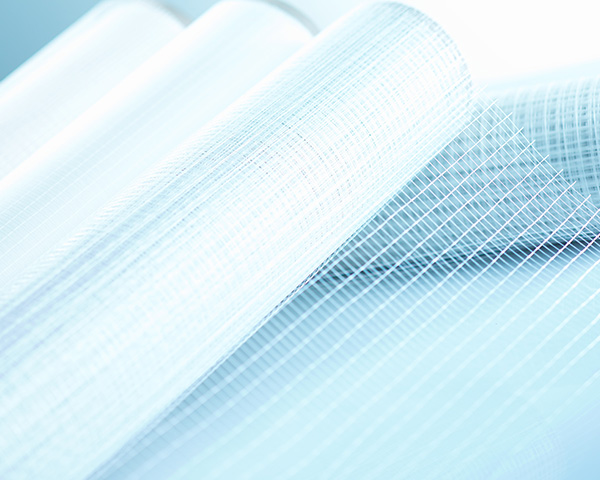

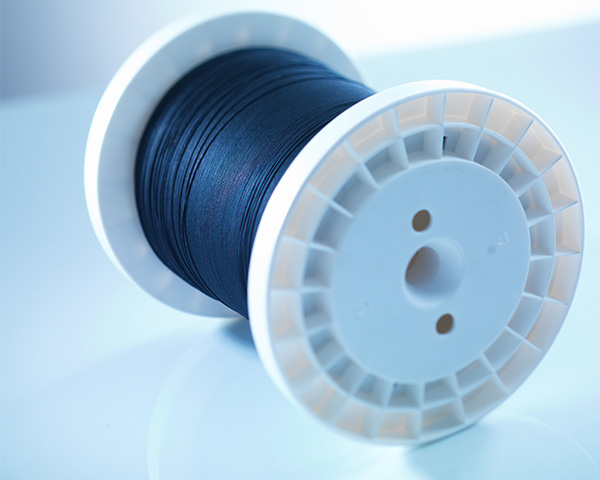

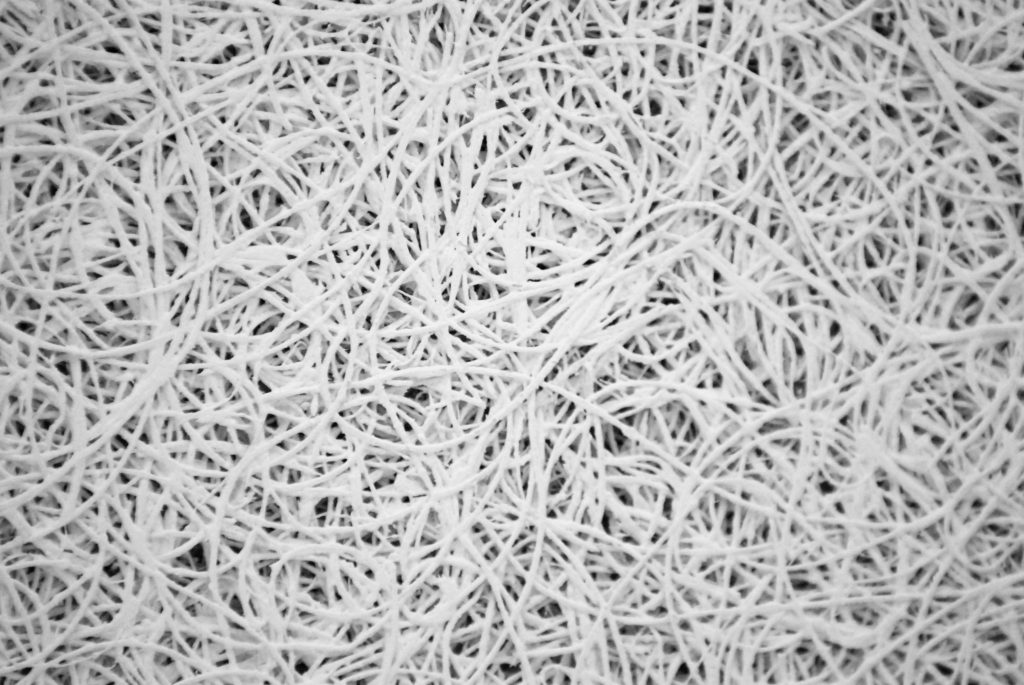

Emanuel Lang composites is a fully integrated flax composite company including spinning, weaving, dyeing and finishing facilities. The company is ideally located in the centre of Europe next to Mulhouse. The flax fibres are coming from “Terre de Lin” in Normandy, just 700 km away from the factories and therefore the sourcing is fully secured. The company benefits from many years of practice and collaboration with many universities and research laboratories which is unique in Europe.

Emanuel Lang composites can also rely on the proximity of Schlumberger, a world-wide manufacturer of flax spinning machines. Emanuel-Lang Composites is highly specialised in coloured flax composites with an in-house laboratory allowing the definition of any personalised request before the production stage.

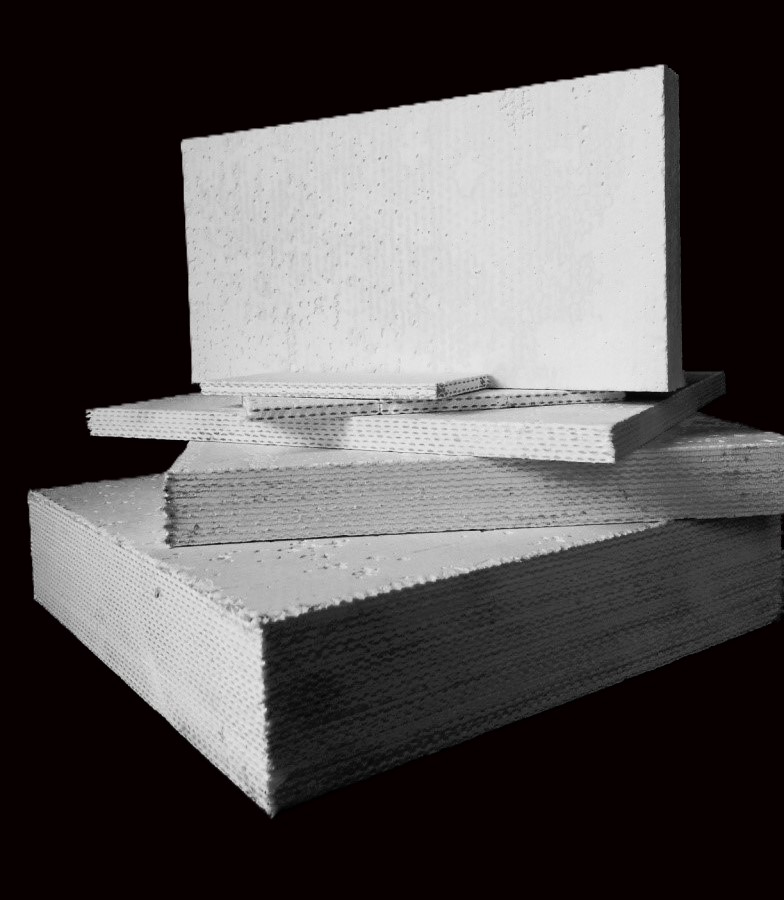

The company benefits from a large experience in multiple sectors including the automotive and the marine industry. Emanuel Lang composites can deal with both thermoplastics and thermosets matrix systems and is working on bio-based solutions.

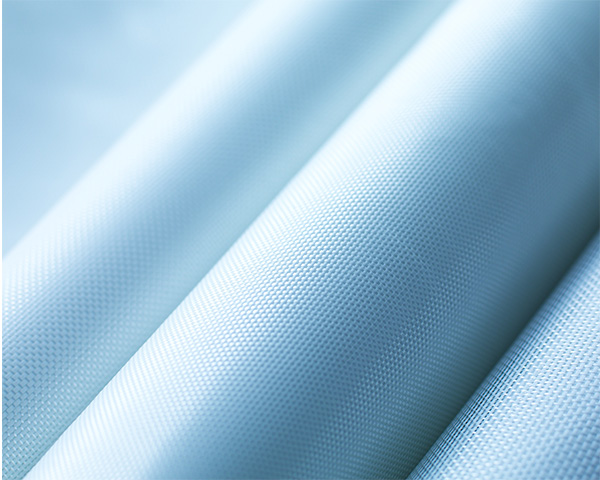

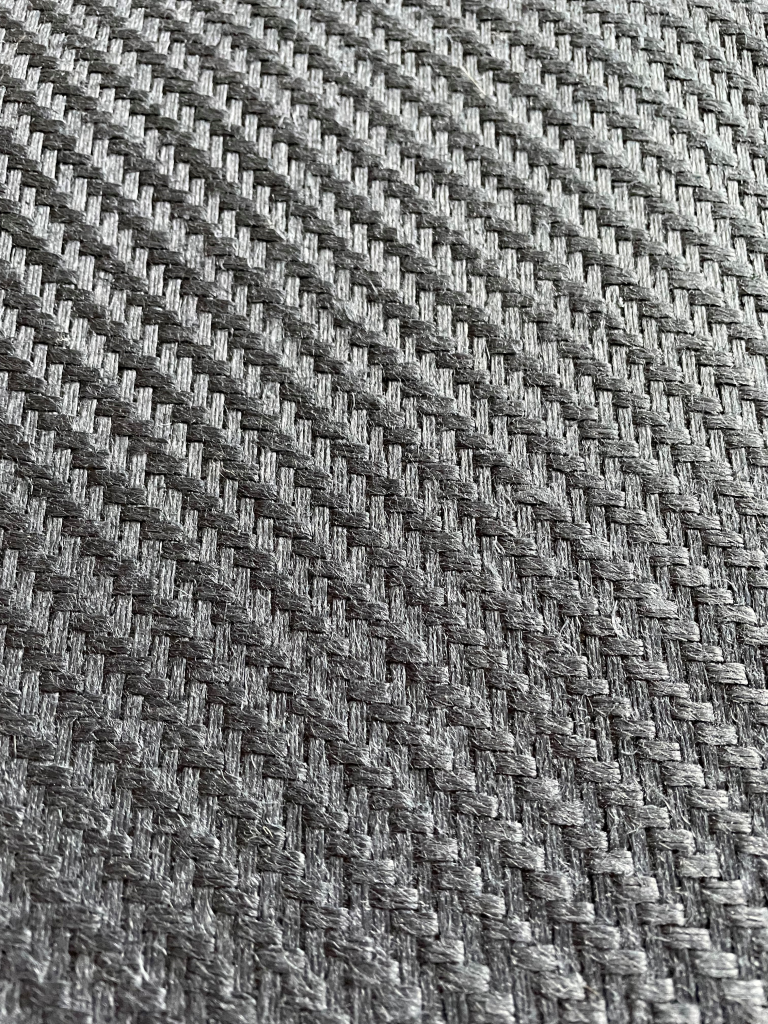

Emanuel Lang Composites can offer a sustainable alternative to carbon with a similar look made with flax, a natural, biobased and biodegradable solution.

Emanuel-Lang Composites is highly specialised in coloured flax to manufacture composite parts. The woven fabric can be mixed with different thermoplastics depending on the applications.

CONTACT US

15 rue Paul Lang – 68560 HIRSINGUE

E-mail : flaxcomposites@emanuel-lang.fr

Tél. : +33 3 89 07 52 07 / +33 6 07 44 48 76