about us :

Located in Rhône Alpes Auvergne and with nearly 50 years of experience STEVTISS is involved in the design, development and manufacture of textiles for technical purposes. We are creator of industrial textile products. Our strenght? Our reactivity. Expertise, know-how and innovation made in France guarantee our quality.

An international presence and a great industrial reactivity in order to respond with precision to any specific request. We develop custom-made solutions for different industrial sectors : aeronoautics/ composite industry/ electrical/ rail/ automotive/ iron&steel/ nuclear/ maritim/ …

Customized and adapted support thanks to an efficient integrated production tool: R&D; warping ; weaving; impregnating/ coating composites; cutting ; clothing industry/ processing.

Our product catalog is representative of all the developments carried out in collaboration with our customers : tapes for electical insulation; prepegs fabrics; reinforcement grid; …

We are able to develop any type of weaving. Come to our stand in order to discover our innovations!

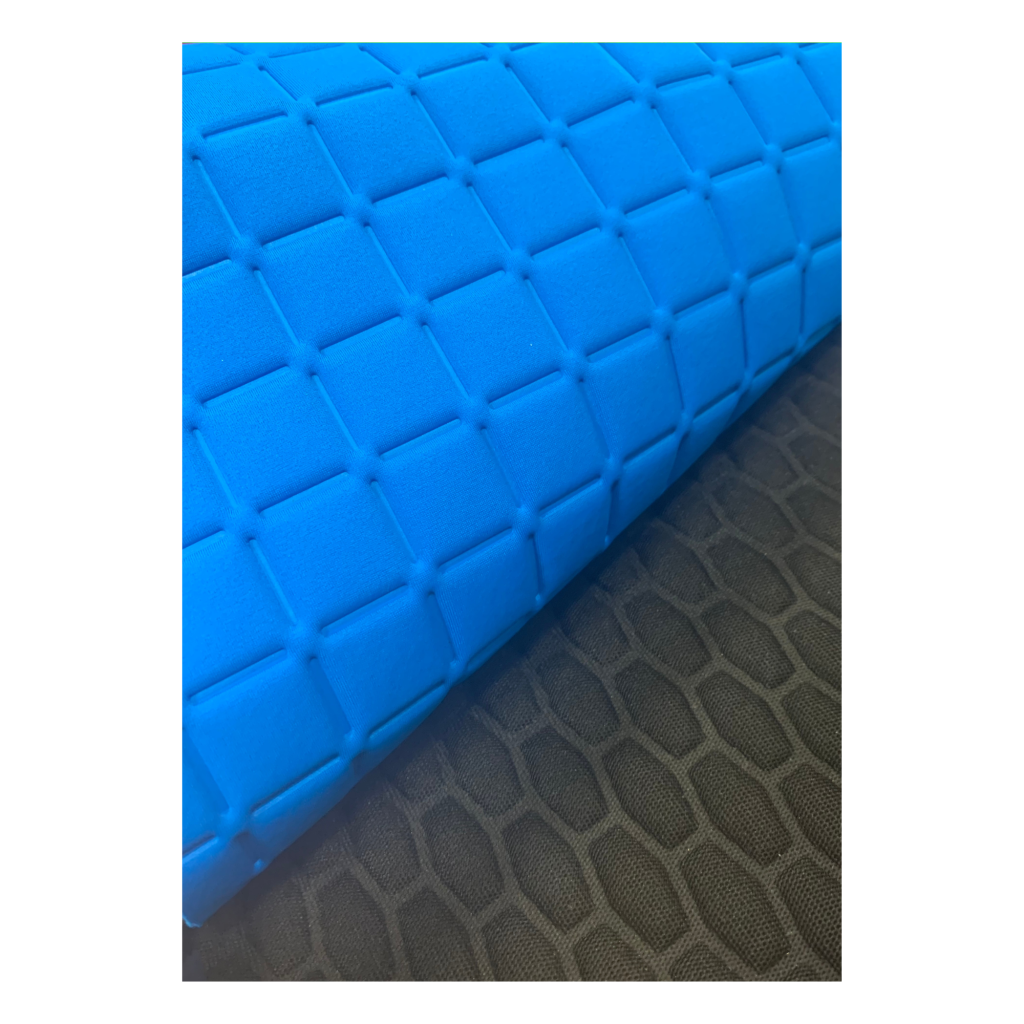

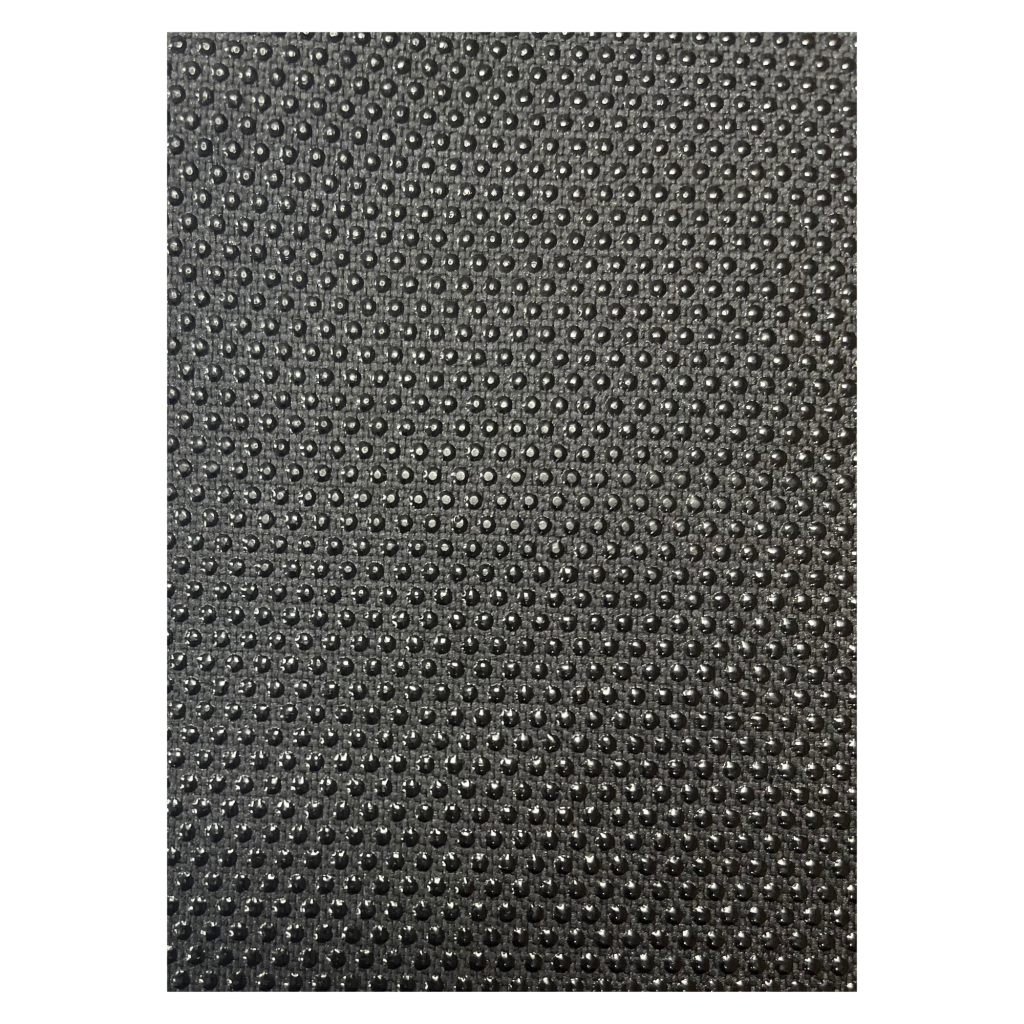

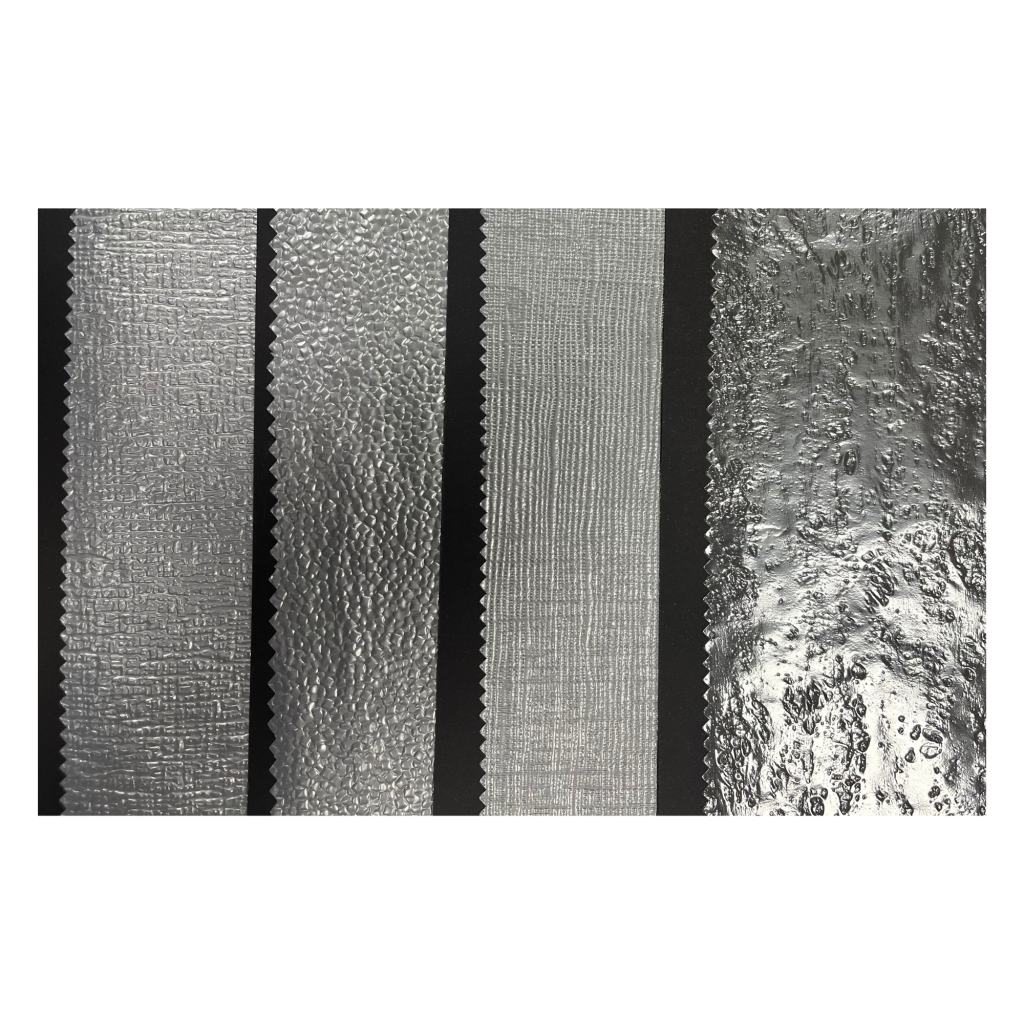

Tape and fabric

From the spool of thread to the loom, we manufacture according to your specifications from width 3 to 600 mm and 600 to 2m60. Woven materials: glass, basalt, aramid, silica, carbon, natural materials (linen, etc.), etc.

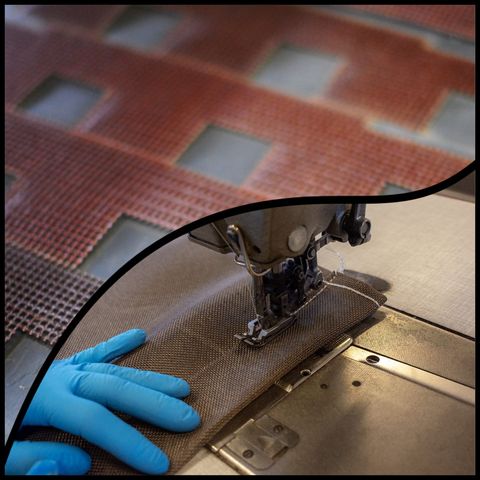

Tailoring workshop and several cutting tools

We have a manufacturing workshop and several cutting tools (automaton, cutting press ranging from small to large series) which allows us once again to make tailor-made products in line with the requests of our customers.

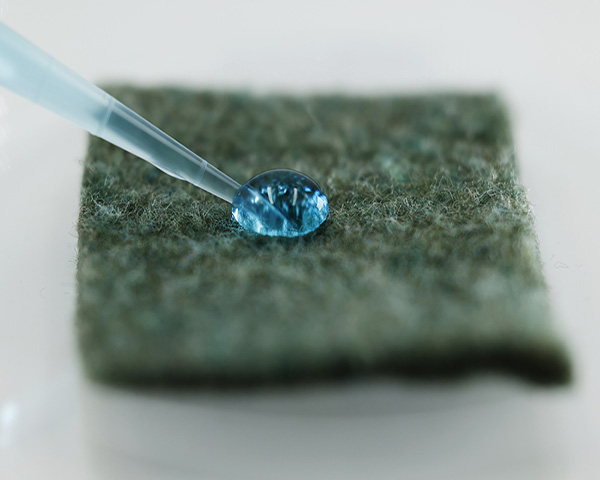

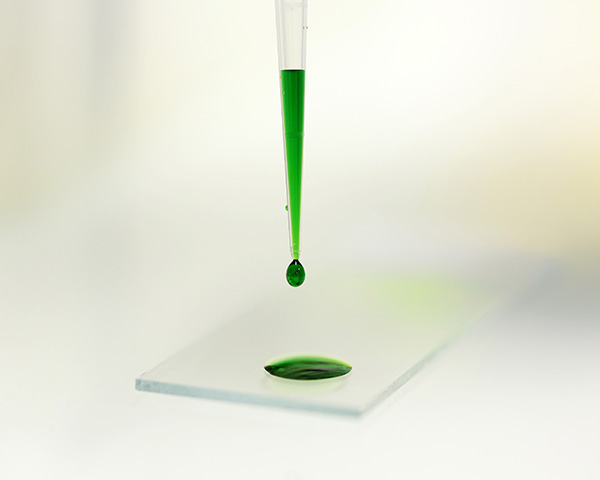

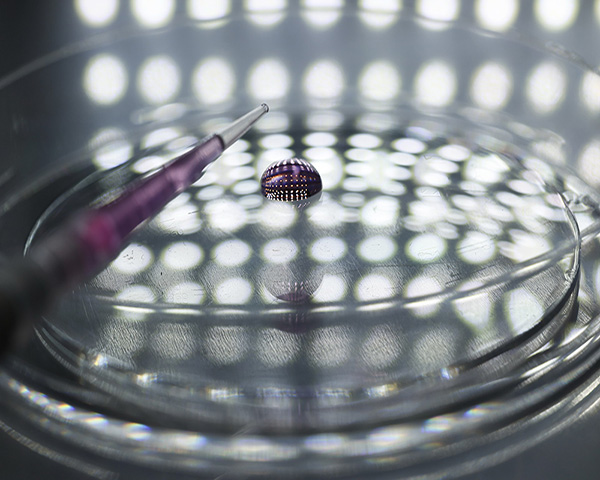

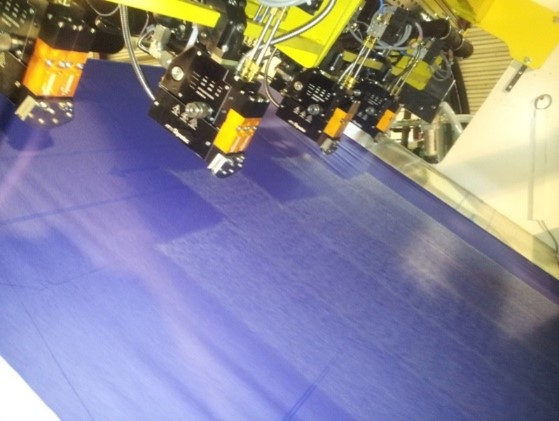

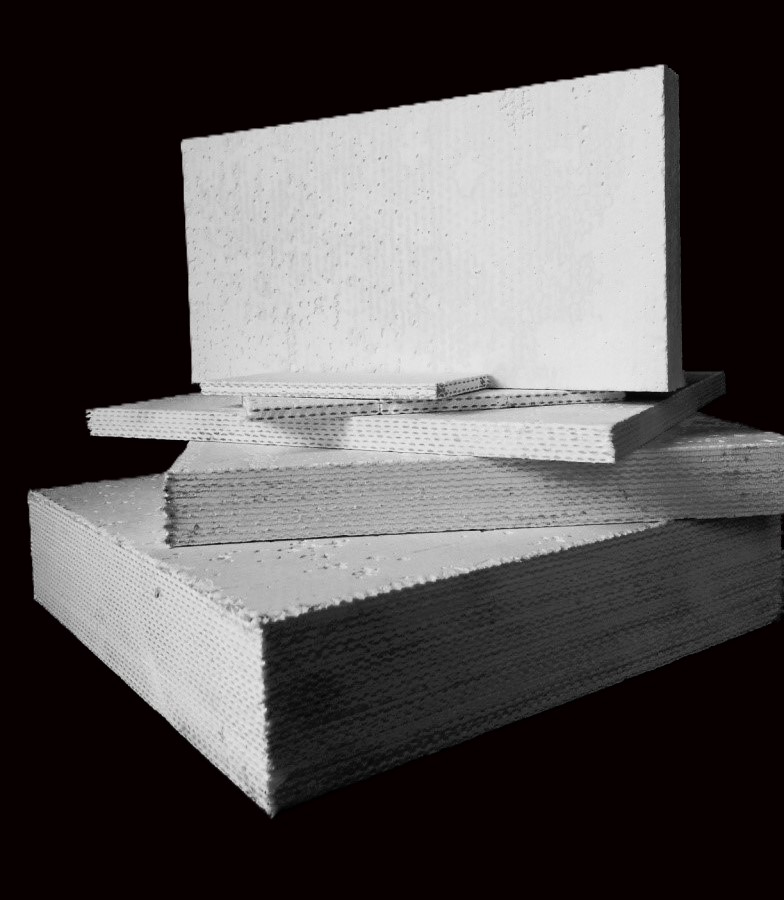

Impregnation line

We have our own impregnation line (maximum width 1,500 mm) which allows us to deposit any type of treatment product supplied or not by the customer.

CONTACT US

64 rue Renaud – 42114 Chirassimont – France

Tél. : + 33 (0)4 77 62 43 13

www.stevtiss.fr