CONTACT US

25, rue Alfred Werner – 68200 MULHOUSE – France

E-mail : contact@textile-alsace.com

Tél. : + 33 (0)3 89 42 98 65 / + 33 (0)3 89 42 98 65

Pôle Textile Alsace : réseau d’entreprises textiles, Grand Est (textile-alsace.com)

Pôle Textile Alsace : réseau d’entreprises textiles, Grand Est (textile-alsace.com)

ROBERT LEVY SAS was founded in 1886 and has an extensive experience for textile recycling.

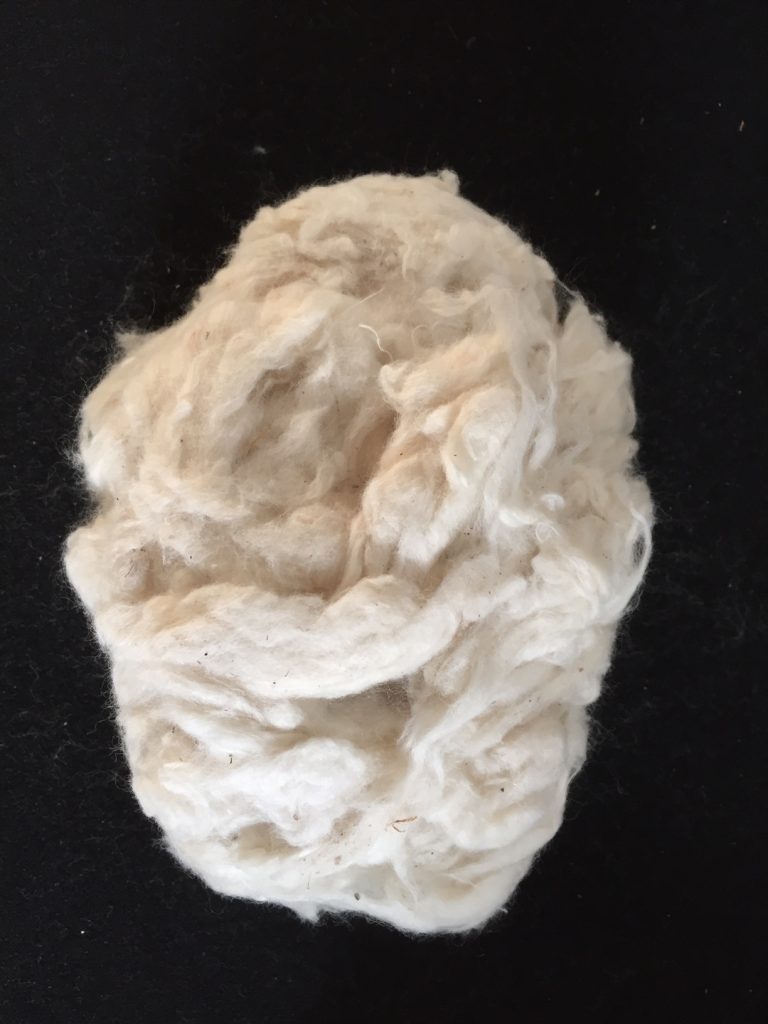

We process and sell 2 ranges of high quality fibers:

1. classical fibers: cleaned cotton waste (pure and blended) and recycled synthetics fibers (white and colored)

2. technical fibers: recycled meta-aramid and para-aramid fibers, pure or blended

Our fibers are used worldwide for spinning, filling and non-woven.

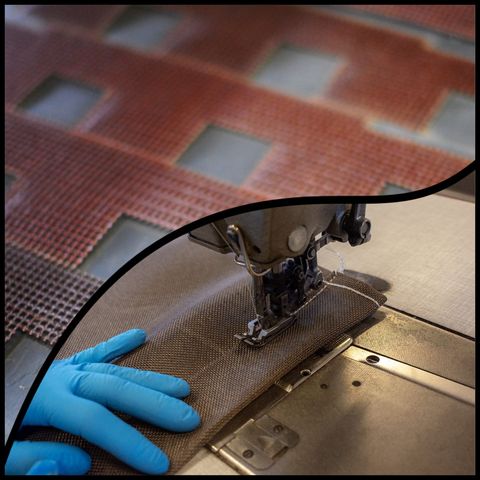

We produce stitchbonded maliwatt non woven made of virgin and recycled fibers

STITCHBONDED NON WOVEN

RECYCLED PARA-ARAMID

RECYCLED SYNTHETICS

Contact : Robert.levy1@wanadoo.fr

Tél. : 00 33 3 29 25 02 12

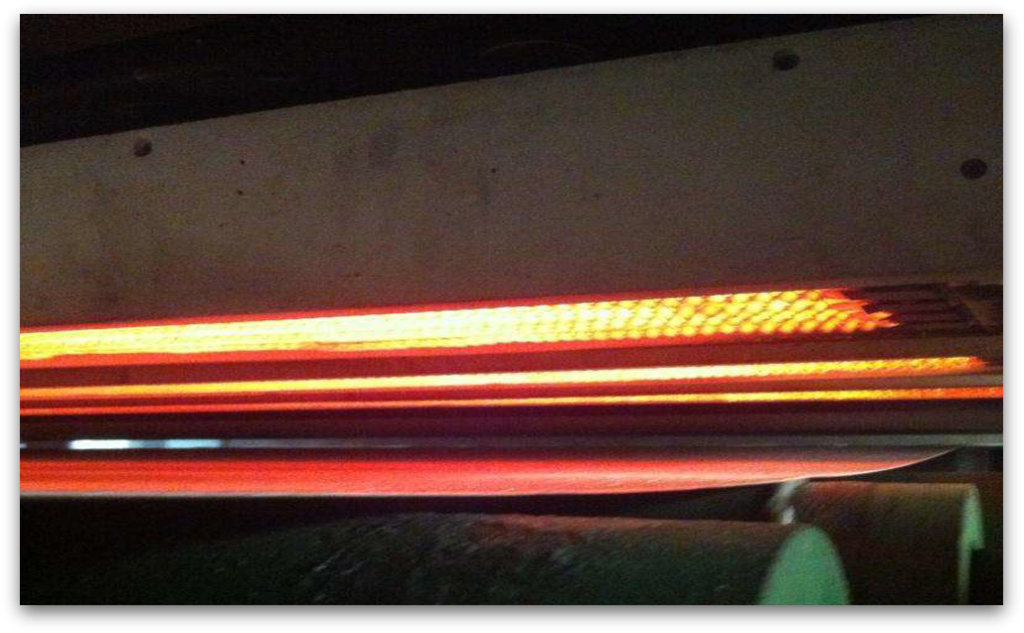

SOPARA is a specialist in infrared heating technologies and the design of special machines for various industries.

Our expertise is based on a complete understanding of thermal process, offering innovative and efficient solutions to meet our customers’ most demanding requirements. Whether for drying, curing, forming or other applications, our infrared heating systems offer unrivalled performance, precision and reliability.

SOPARA designs and manufactures special machines and heating elements to suit each customer’s needs. We work in partnership with our customers to understand their requirements and design tailor-made, intelligent solutions.

We serve a wide range of industries, including automotive, aerospace, textile, food, composite and many others. Our commitment to innovation, quality and customer service has enabled us to build strong relationships with our customers around the world.

At SOPARA, our mission is to be our customers’ privileged partner, providing them with high-quality, innovative and reliable infrared heating solutions. We remain at the forefront of technology to meet tomorrow’s challenges and contribute to our customers’ success.

Continuous coating drying : by positioning infrared emitters above and below a continuous product, you can significantly accelerate drying speed. Reduce your process footprint and optimize your space.

Heated cylinders for textile drying: our heated cylinders are equipped with infrared emitters inside. This gives them all the advantages of infrared heating: low consumption, low maintenance, low inertia, high performance.

Gelling of PVC: our infrared heating systems rapidly achieve homogeneous gelling, while consuming less than a standard hot-air oven.

Contact : contact@sopara.com

Tél. : +33(0)4 72 81 23 00 / +33(0)4 72 81 23 06

www.sopara.com

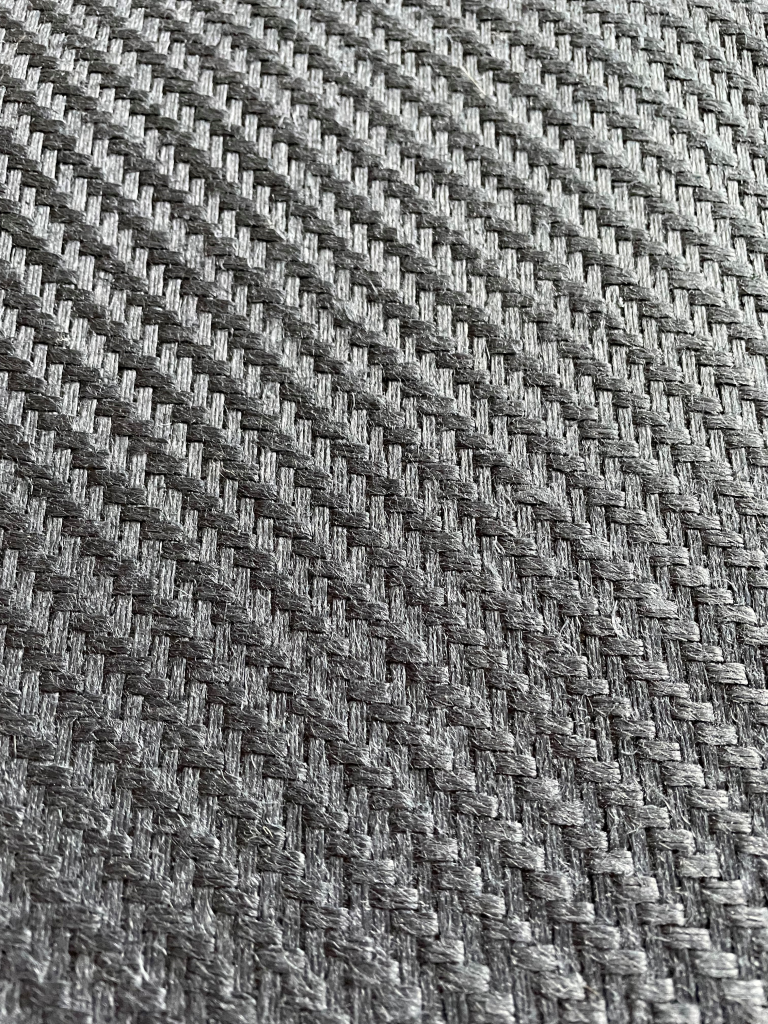

Emanuel Lang composites is a fully integrated flax composite company including spinning, weaving, dyeing and finishing facilities. The company is ideally located in the centre of Europe next to Mulhouse. The flax fibres are coming from “Terre de Lin” in Normandy, just 700 km away from the factories and therefore the sourcing is fully secured. The company benefits from many years of practice and collaboration with many universities and research laboratories which is unique in Europe.

Emanuel Lang composites can also rely on the proximity of Schlumberger, a world-wide manufacturer of flax spinning machines. Emanuel-Lang Composites is highly specialised in coloured flax composites with an in-house laboratory allowing the definition of any personalised request before the production stage.

The company benefits from a large experience in multiple sectors including the automotive and the marine industry. Emanuel Lang composites can deal with both thermoplastics and thermosets matrix systems and is working on bio-based solutions.

Emanuel Lang Composites can offer a sustainable alternative to carbon with a similar look made with flax, a natural, biobased and biodegradable solution.

Emanuel-Lang Composites is highly specialised in coloured flax to manufacture composite parts. The woven fabric can be mixed with different thermoplastics depending on the applications.

E-mail : flaxcomposites@emanuel-lang.fr

Tél. : +33 3 89 07 52 07 / +33 6 07 44 48 76

TEXTILE GRAND EST is a dynamic professional business network for textiles and soft materials located in the East of France (Alsace, Lorraine, Champagne Ardenne), the closest Textile Cluster to the German and Swiss borders, well known for its expertise in fiber sciences and textile manufacturing over several centuries.

We gather a large number of companies, laboratories, schools and technical centres.

Our mission is to help our textile network build, grow and consolidate their competitiveness thanks to innovative and biobased textile solutions.

We encourage and develop collaborative innovation in processes and products, through a range of dedicated services :

– Networking to facilitate business opportunities

– Access to information on textile innovation and Industry 4.0 driven

– Acceleration of innovative sustainable textile solutions from raw materials to final product

– Promotion of the textile industry in the region

E-mail : contact@textile-alsace.com

Tél. : + 33 (0)3 89 42 98 65 / + 33 (0)3 89 42 98 65

www.textile-alsace.com

Booth 12.1-E59

#sensors # textile # yarn cutters # yarn break sensors # yarn tension sensors #speed and presence sensors

Since 1990, FIL CONTROL is specialized in developing, producing and selling sensors and yarn cutters for the textile machinery industry.

Thanks to the skills and experience of our engineering department, in electronic, mechanic and design, we can answer to generic needs, but also to any kind of bespoken demands, by adapting or developing our products to answer to each specific application of our customers.

With a reactive and competent team, coupled with reliable products, Fil Control has become one of the most famous brand on this market.

We sell our products all around the world, through our sales department and our agent network.

The MOS-LT is a non-contact yarn break opto-electronic sensor.

To control the presence of yarns while linear motion. When the yarn breaks or stops, the sensor will give the information to the machine. It can activate a yarn cutter or stop the position

Fork Size : 2mm fork

The MOS-L is a non-contact yarn break opto-electronic sensor.

To control the presence of yarns while linear motion. When the yarn breaks or stops, the sensor will give the information to the machine. It can activate a yarn cutter or stop the position.

Fork Size : 1.5mm fork

The MYT-T is a load cell sensor devoted to assembling, winding and texturing operations: medium and high count (400 to 10 000 dTex) and high tensioned yarns (up to 4000 g).

TEXTI SONICS SAS designs and manufactures its specific range of ultrasonic welding and sealing / slitting devices.

These equipments offer a great technical versatility for straight or curved operations, or multi layers in continuous assembling, in multi-spots sealing, joining end to end narrow or wide webs, …

Application areas

FIBC industries (Big Bags, Jumbo bags, bulk bags, …), machines and looms manufacturers, packaging, technical textiles, geotextiles, non-woven, medical, awnings, plastics, flexible products, …

Technology 1

TEXTI SONICS’ worldwide patented “approach system” called “Sonic Touch Control” guarantees optimal cutting results and enables a lowest wear of sonotrodes and tools.

Technology 2

For “synthetic thermo-fusible fabrics”, the sealing/slitting technology improves the finishing of the fabrics :

– with very strong, soft and clean sealed edges (no fraying) ;

– with high productivity of the sealing and slitting operations ;

– without any over-thickness ;

– in the respect of original colours of the products to be converted ;

– without any burnt or not even yellowing edges.

ULTRA STAR Genius 400-35 : device for continual sealing points with integrated mechanical cutting and equipped with patented “Sonics Touch Control” system, to be installed on machines or looms.

For big bags, technical textiles, non woven, etc.

Slitter 400-35 : Ultrasonic equipment for continuing sealing-slit to be installed on machines or production lines. Large possibility of cutting results thanks to 18 different cutting angles.

For technical textiles, non woven, packing, medical, plastics., etc.

Table Genius 400-35 : Sealing/cutting device, operated manually.

Compact device, very easy to install and to use. Can also be installed in a groove for straight cuts.

For : awnings, technical textiles, non woven, plastics, packing, medical, etc.

Contact : contact@textisonics.com

Tél. : +33 (0)4 77 54 91 63 90 / +33 (0)6 85 66 05 80

Located near to Rouen in Normandy, APRONOR is recognised as a key player and leader in technical textiles. With its positioning on diverse markets, a 4,000m² logistics hub and one of the largest stock of technical textiles in Europe, APRONOR can quickly ship out its products to anywhere in the world. Innovation, reliability, responsiveness and high-quality, peronalised service are the main values that drive our teams so we can offer you a full range of solutions and responses to your needs.

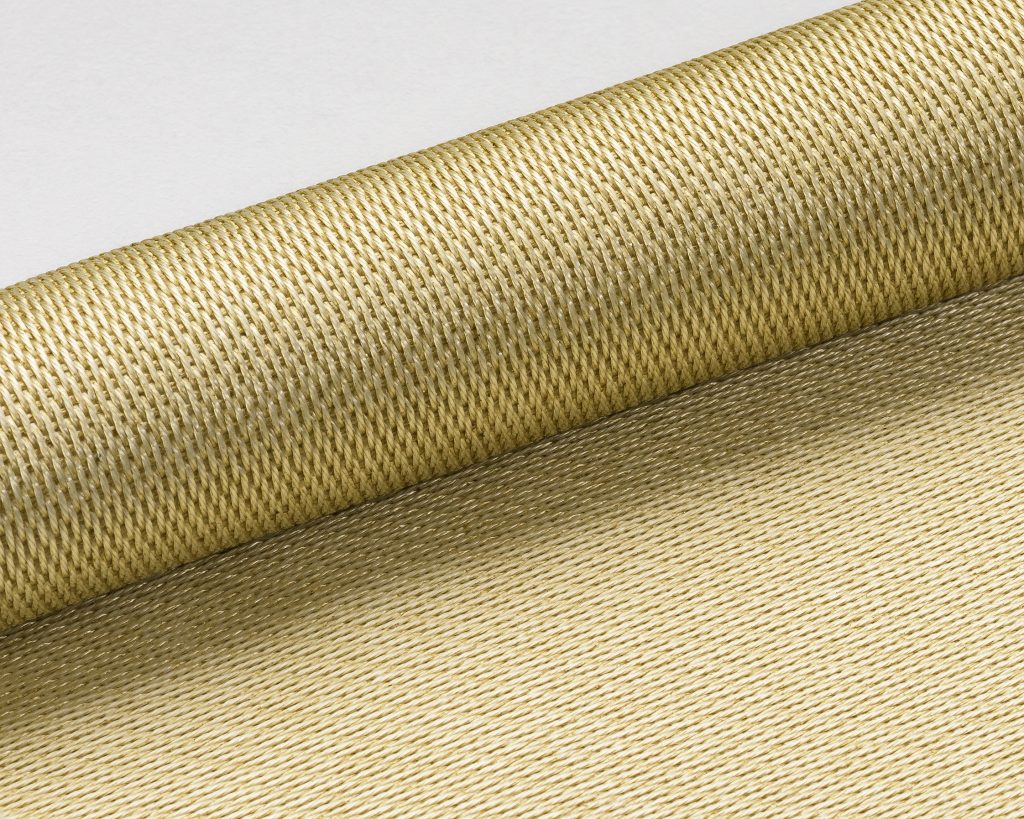

GLASS FABRICS

Glass fabrics are made from a glass fibre that can withstand temperatures of up to 800°C.

STRONG POINTS : Non-combustible, Temperature resistant, Insulating

APPLICATIONS : Foundry, Thermal insulation and lagging, Steel industry, Glass industry, Heat and fire protection

SILICA FABRICS

Silica fabrics are made from a silica fibre can withstand temperatures of up to 1000°C.

STRONG POINTS : High temperature resistance, Good insulation capacity, Enhances thermal insulation

APPLICATIONS : Insulation/Lining, Passive fire protection, Heat shielding/Cover protection, Curtains

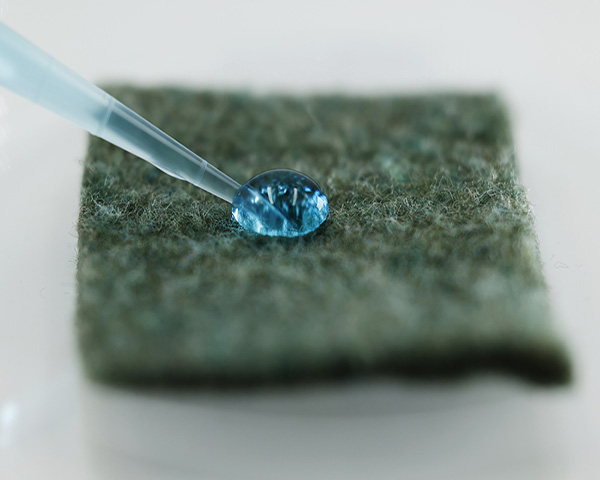

TECHNICAL FELTS

Technical felts are very good insulators due to thier specific composition.

STRONG POINTS : Vibration reduction, Mechanical strength, Thermal insulation

APPLICATIONS : Thermal and acoustic insulation, Filtration, Boiler compensator and fields, Flue gas purification

Contact : commercial@apronor.com

Tél. : +33 (0)2 35 33 04 10 / +33 (0)2 35 33 70 37

www.apronor.com

Located in Rhône Alpes Auvergne and with nearly 50 years of experience STEVTISS is involved in the design, development and manufacture of textiles for technical purposes. We are creator of industrial textile products. Our strenght? Our reactivity. Expertise, know-how and innovation made in France guarantee our quality.

An international presence and a great industrial reactivity in order to respond with precision to any specific request. We develop custom-made solutions for different industrial sectors : aeronoautics/ composite industry/ electrical/ rail/ automotive/ iron&steel/ nuclear/ maritim/ …

Customized and adapted support thanks to an efficient integrated production tool: R&D; warping ; weaving; impregnating/ coating composites; cutting ; clothing industry/ processing.

Our product catalog is representative of all the developments carried out in collaboration with our customers : tapes for electical insulation; prepegs fabrics; reinforcement grid; …

We are able to develop any type of weaving. Come to our stand in order to discover our innovations!

Tape and fabric

From the spool of thread to the loom, we manufacture according to your specifications from width 3 to 600 mm and 600 to 2m60. Woven materials: glass, basalt, aramid, silica, carbon, natural materials (linen, etc.), etc.

Tailoring workshop and several cutting tools

We have a manufacturing workshop and several cutting tools (automaton, cutting press ranging from small to large series) which allows us once again to make tailor-made products in line with the requests of our customers.

Impregnation line

We have our own impregnation line (maximum width 1,500 mm) which allows us to deposit any type of treatment product supplied or not by the customer.

Tél. : + 33 (0)4 77 62 43 13

www.stevtiss.fr

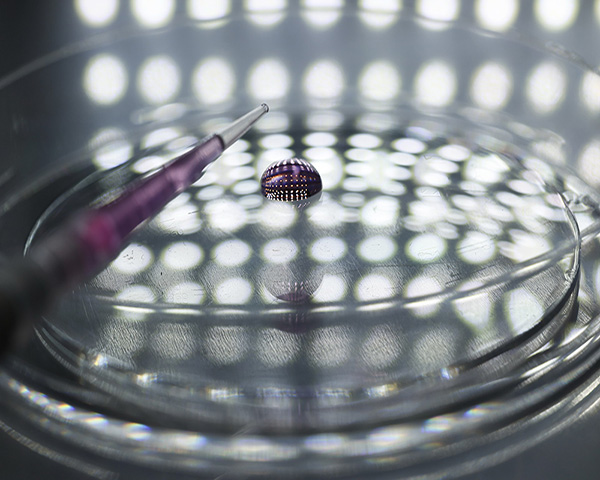

VirHealth is an independent laboratory specializing in virology and microbiology.

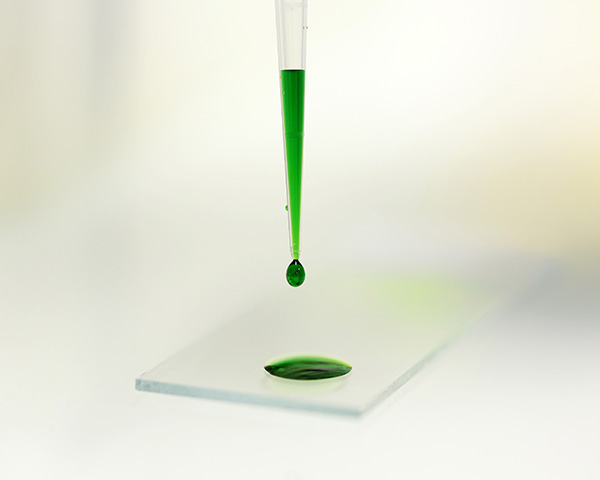

The Materials Department at VirHealth offers a broad spectrum of tests to assess the antiviral and antibacterial performance of diverse antimicrobial textiles, materials, and coatings.

The offer includes international/US standards (ISO/ASTM), preliminary screening tests, and bespoke protocols (hydrophobic textiles…).

Our VirHealth lab collection features an extensive array of 80 bacterial and viral strains. We also provide the option to acquire additional viruses to meet the testing needs of our clients. All tests can be conducted in a BioSafety Laboratory level-3, using pathogenic viral strains.

For further information, please visit: www.virhealth.fr

VirHealth, a virology laboratory, performs the ISO 18184 standard to determine the antiviral activity of textile products. We can also assess antiviral activities on hydrophobic textiles following our internal procedures.

VirHealth conducts the ISO 21702 standard to measure antiviral activity on plastics and other non-porous surfaces. We also perform tests on antimicrobial paper, leather, and other porous materials based on our internal procedures.

We perform the ASTM E 2180-18 standard to determine the activity of incorporated antimicrobial agents in polymeric or hydrophobic materials. We can also assess antiviral activities on hydrophobic materials following our internal procedures.

E-mail : contact@virhealth.fr

Tél. : + 33 (0)4 81 06 17 21 / + 33 (0)6 07 42 12 14

www.virhealth.fr