about us :

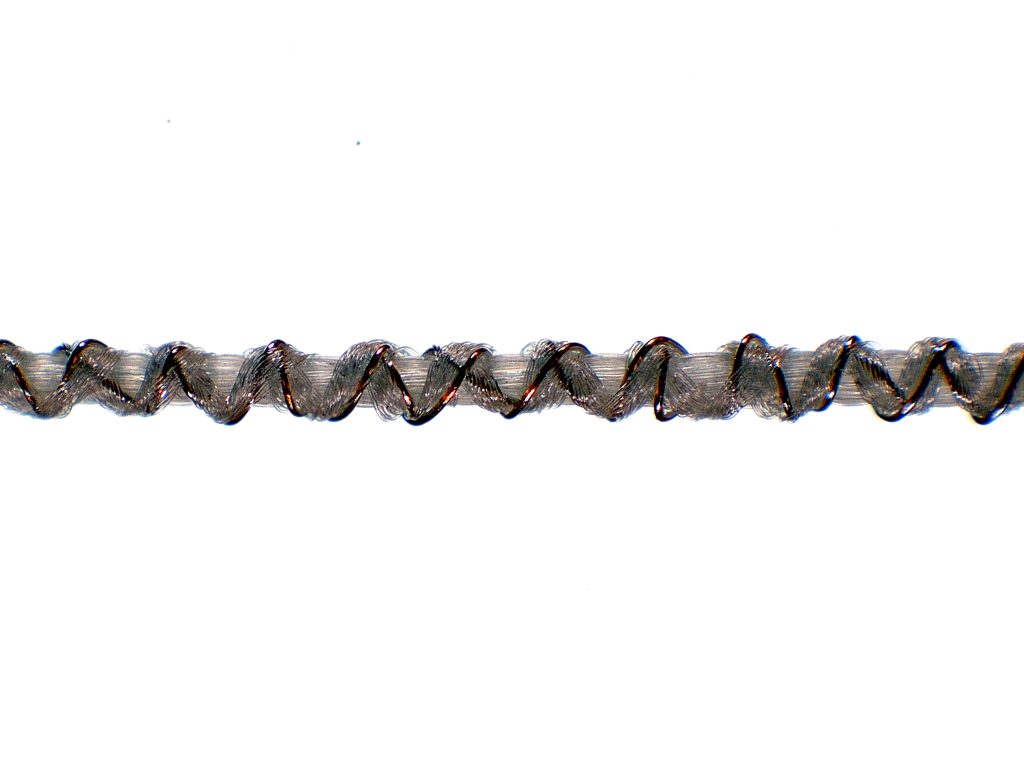

PRONEEM has been a global actor in biotechnological solutions dedicated to functionalizing textiles in the health, cosmetics, and detergent industries since 2003.

Proneem offers a thoughtful and committed approach with 360-degree service, thanks to its in-house R&D laboratories, production plant, and regulatory department.

Their solutions encompass biocides, thermo-regulation, and moisture management across a broad spectrum. With its biobased solutions, Proneem contributes to a sustainable future.

LACTIC®, a biobased antimicrobial, is designed to inhibit the growth of odor-causing bacteria. This innovative solution significantly reduces the necessity for frequent laundering, offering a sustainable approach to save energy and water.

Block bedbugs®, the ultimate solution for long-lasting bed bug protection. Its biobased formula without harmful chemicals and permethrin-free effectively repels bed bugs, Block bedbugs® is the perfect choice for safe and reliable bed bug protection.

Protector® is an innovative mosquito repellent that provides integrated and long-lasting protection. It is permethrin-free and effectively repels mosquitoes, ticks, and bedbugs. Protector® offers optimal protection under all conditions of use.

CONTACT US

1 impasse Paradou – 13009 MARSEILLE – France

E-mail : info@proneem.com

Tél. : + 33 (0)3 20 72 00 26 / + 33 (0)6 87 78 51 54

https://www.proneem.com/