about us :

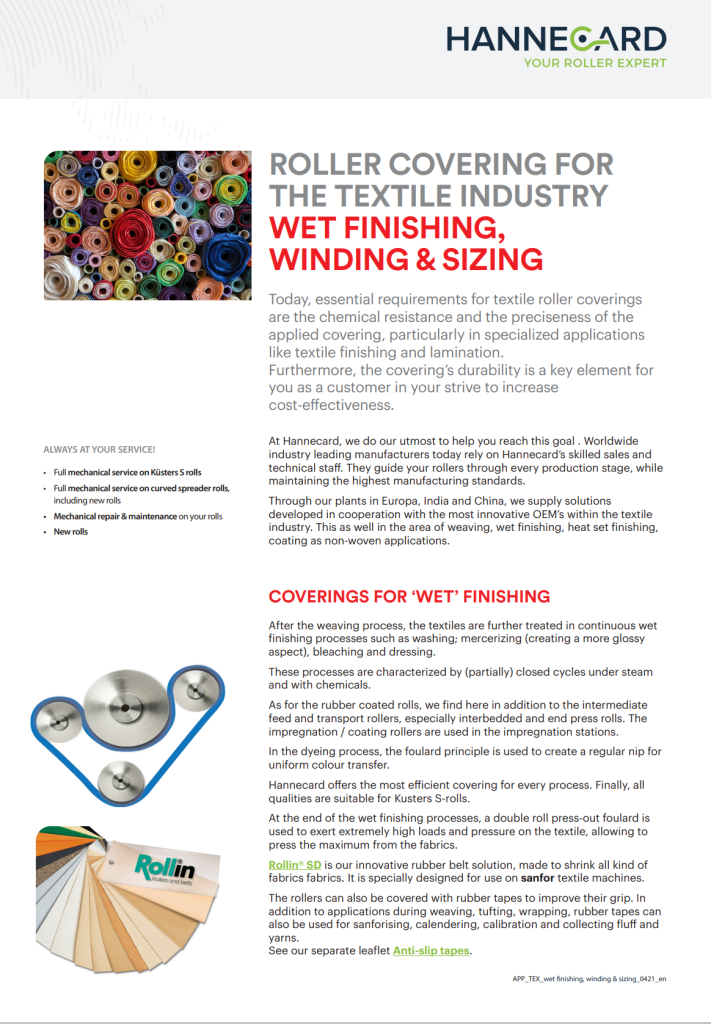

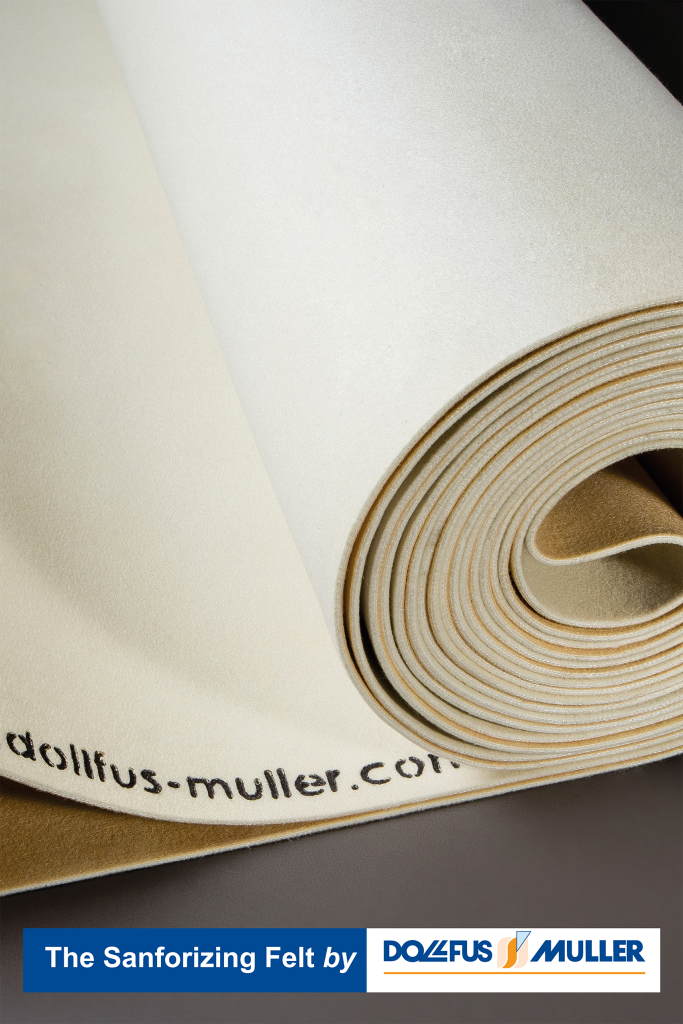

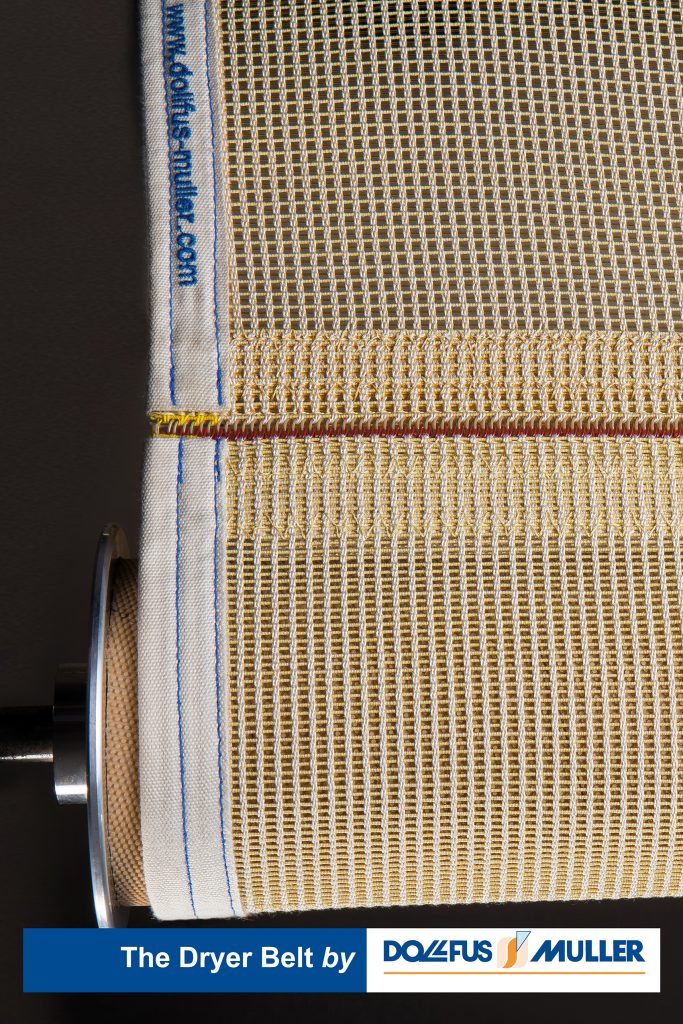

UCMTF is the trade association grouping the French Textile Equipment Manufacturers. UCMTF’s members are particularly strong in long fibre spinning (wool, acrylic …), yarn twisting and control (including technical yarns), space-dyeing, heat setting for carpet yarns, carpet systems, dyeing and finishing, felts and belts for finishing processes, nonwovens, air conditioning of textile plants, and recycling processes of textile materials. Their total annual consolidated turnover is close to 1 billion Euros. Most of the turnover is exported to Asia, EMEA and the Americas. Innovation and service are embedded in the DNA of UCMTF’s members; they are long term technology partners of their customers. Most of them are small or medium-sized companies, focused on specialty equipments which can be custom made to help the customers develop new products, produce them in sustainable and secure industrial processes. Their goal is to help their customers to increase both their turnovers and profits.

Europe remains the major textile equipment cutting-edge, innovative centre in the world. The National associations like UCMTF have joined together to own and manage, through the Cematex (European Committee of Textile Machinery Manufacturers), the ITMAs, in Europe every 4 years in a different country and in Asia every 2 years.

As a member of the Cematex’ board, UCMTF takes part in the decisions made by the Cematex for the organization of our industry and of its exhibitions.