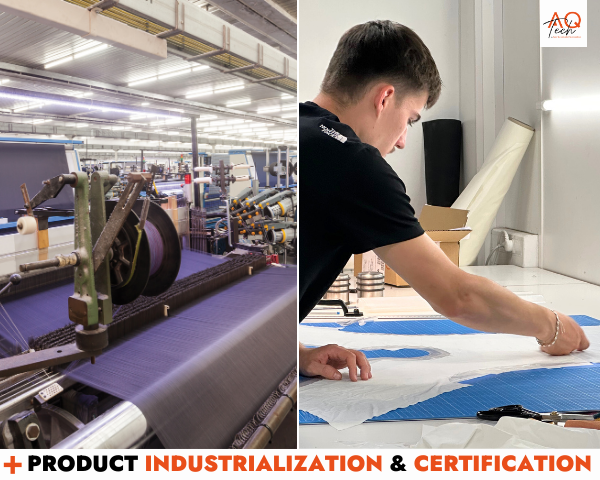

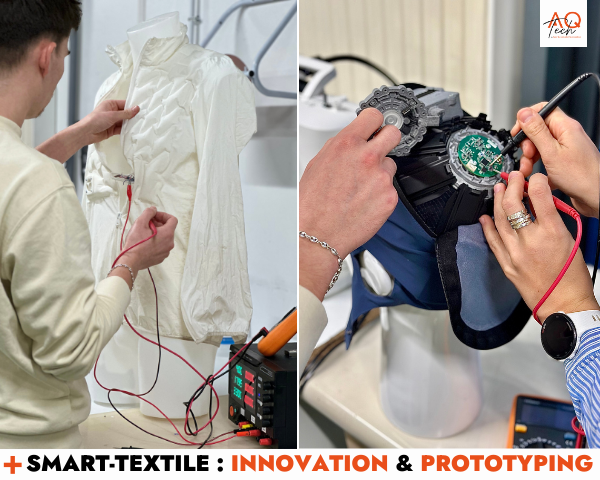

about us :

MASSEBEUF TEXTILES is a family French owned company specialized in conception and production of filament yarns with high added value for textile and technical use. Our technical yarns are created with all kinds of yarns (synthetic, organic, glass fibers, aramid fibers, metallic yarns etc.) by various process: covering, twisting, cabling, texturing, and continuous chemistry treatment (coating, impregnation). The company is involved in different markets: medical, hosiery, personal, protection equipment, sport, industrial, transport; and exports all around the world. MASSEBEUF TEXTILES is certified ISO 9001 and has the OEKOTEX label for specific yarns.

Thanks to our control over the whole chain, (design, development, production), we can provide appropriate expertise and support to build together a product that will deliver highest value to end users. Developing these synergies is key for better efficiency, reduced development cycles and better value.

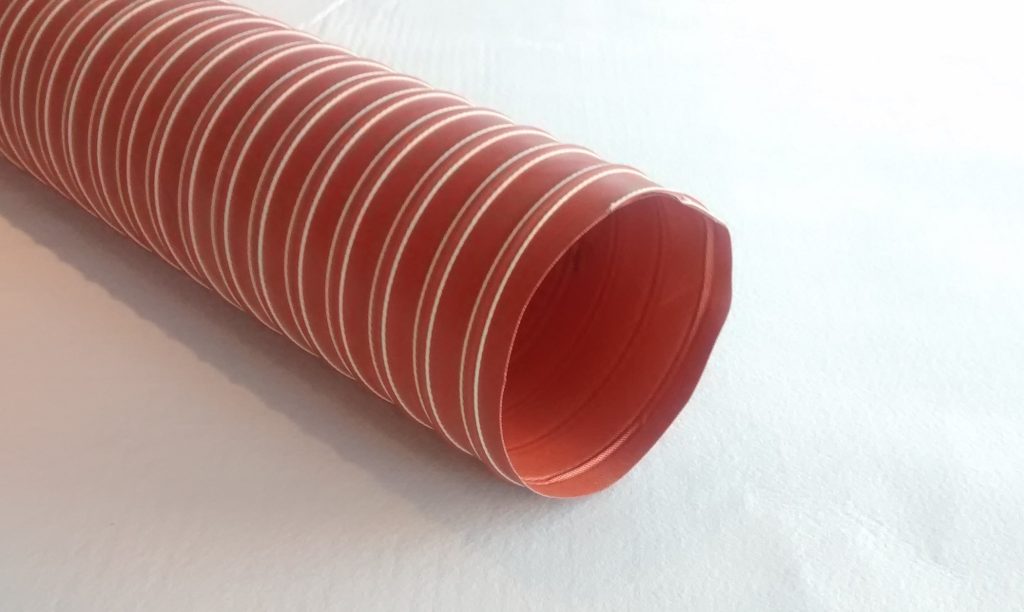

Silicotex

Silicotex® yarn combines silicon – and multifilament properties with an innovative patented process in order to deliver anti-slippery effect. Silicotex® can be directly inserted in knitting, weaving, or braiding to bring grip in clothing, medical and sports applications.

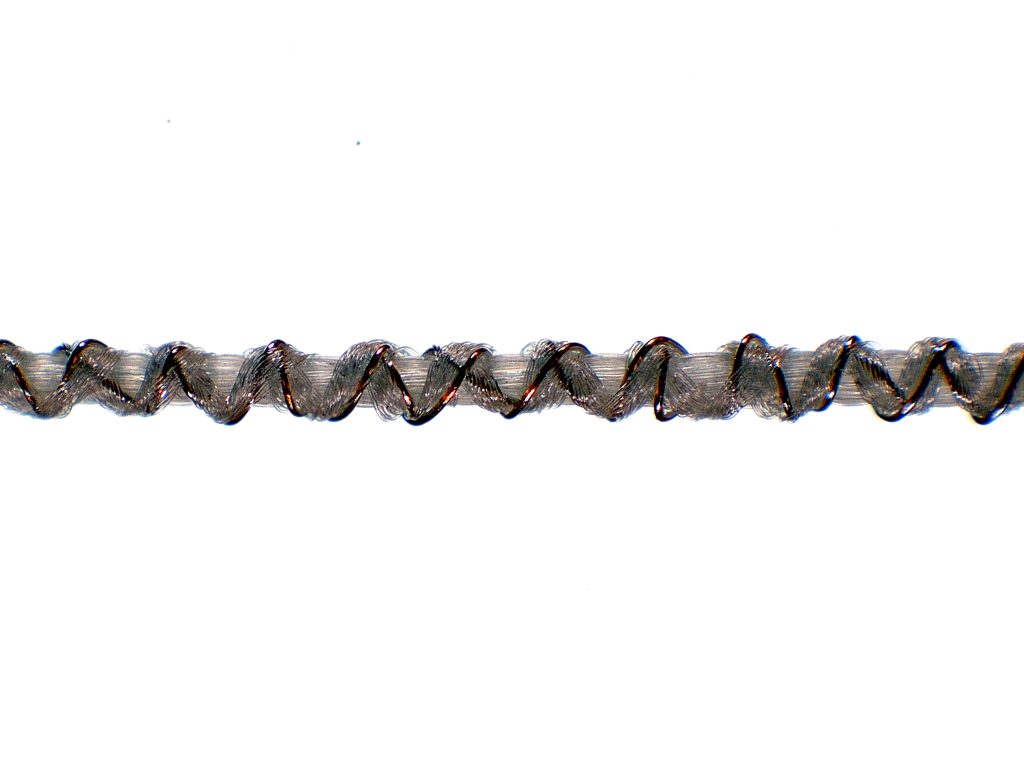

Conductive

Thanks to our wire assembling expertise, we use the best combinations of materials and technologies to develop conductive yarns for all textile applications where electrical conductivity is necessary: EMI shielding, thermal application, antistatic…

PU protection

Massebeuf Textiles offers a new range of technical yarns by providing a polymeric layer to a yarn to improve its abrasion resistance for better durability of textile. The protective yarn can be polyamid, polyester, glass fiber, carbon, linen, and others.

CONTACT US

135 Route de la Fabrique – 07380 Pont de Labeaume – France

E-mail : commercial@massebeuf-ft.com

Tél. : + 33 (0)4 75 87 82 10 / + 33 (0)4 75 61 12 68

www.massebeuf-textiles.com