about us :

TEXTI SONICS SAS designs and manufactures its specific range of ultrasonic welding and sealing / slitting devices.

These equipments offer a great technical versatility for straight or curved operations, or multi layers in continuous assembling, in multi-spots sealing, joining end to end narrow or wide webs, …

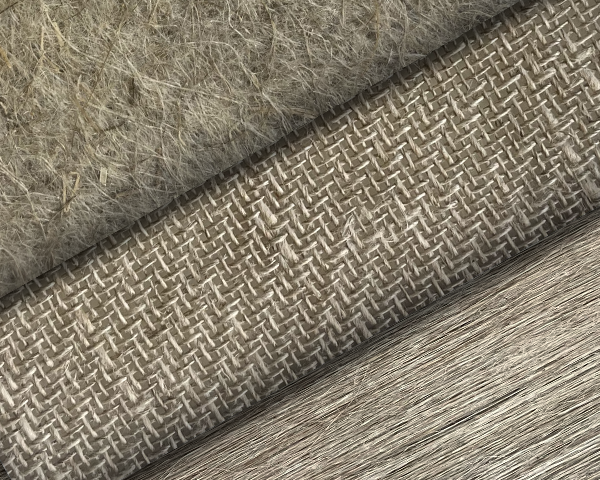

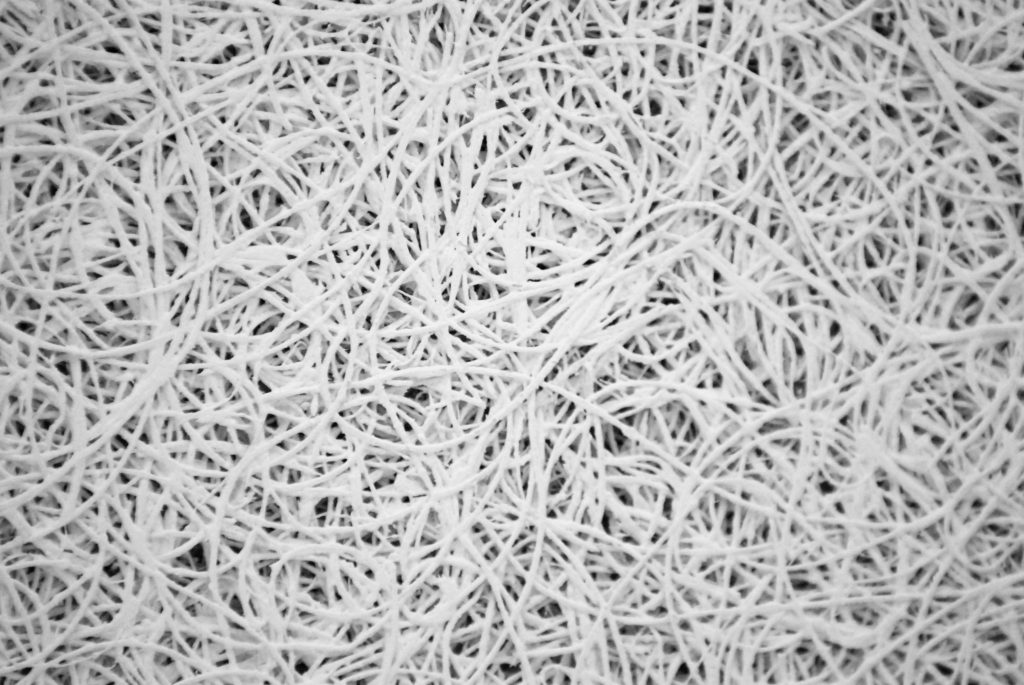

Application areas

FIBC industries (Big Bags, Jumbo bags, bulk bags, …), machines and looms manufacturers, packaging, technical textiles, geotextiles, non-woven, medical, awnings, plastics, flexible products, …

Technology 1

TEXTI SONICS’ worldwide patented « approach system » called « Sonic Touch Control » guarantees optimal cutting results and enables a lowest wear of sonotrodes and tools.

Technology 2

For “synthetic thermo-fusible fabrics”, the sealing/slitting technology improves the finishing of the fabrics :

– with very strong, soft and clean sealed edges (no fraying) ;

– with high productivity of the sealing and slitting operations ;

– without any over-thickness ;

– in the respect of original colours of the products to be converted ;

– without any burnt or not even yellowing edges.

ULTRA STAR Genius 400-35 : device for continual sealing points with integrated mechanical cutting and equipped with patented « Sonics Touch Control » system, to be installed on machines or looms.

For big bags, technical textiles, non woven, etc.

Slitter 400-35 : Ultrasonic equipment for continuing sealing-slit to be installed on machines or production lines. Large possibility of cutting results thanks to 18 different cutting angles.

For technical textiles, non woven, packing, medical, plastics., etc.

Table Genius 400-35 : Sealing/cutting device, operated manually.

Compact device, very easy to install and to use. Can also be installed in a groove for straight cuts.

For : awnings, technical textiles, non woven, plastics, packing, medical, etc.