Booth 12.1-E79E

#Innovation #SmartYextile #SmartComposite #Sustainable #FlexHeater #FlexSensor

about us :

MCVE Technologie is an industrial solutions provider for printed electronics. We manufacture multifunctional fabrics that can be embedded in composite materials or others product. Our EOPROM® formulation enables the manufacturing of electrical copper circuits and electronic functions.

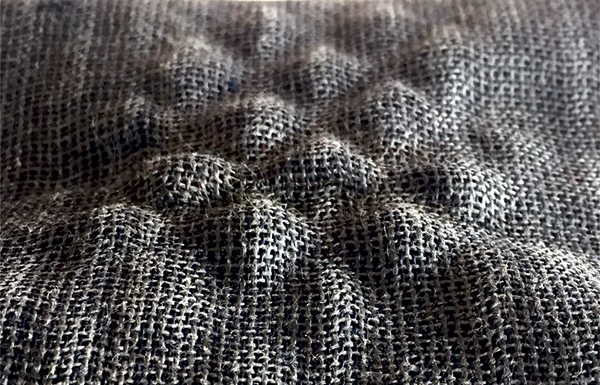

The EopromFlex® process uses the screen printing deposition method as well as copper plating baths on flexible fabrics made of glass, polyester, polyamide or organosheet bio sourced. Copper is a familiar product for electronic people and is a strong raw material that allows a robust connection between the printed function and the electronics thanks to its solderability. MCVE’s technology is for mass production and we bring industrial cost down for embedded heaters, SHM (Structural Health Monitoring), or antenna application.

Our EOPROM® paste provides excellent adhesion on different flexible fabrics glass fibers for smart composite manufacturing. The EOPROM® paste is a precursor to the metallization, so various metals can be deposited, in particular copper but also nickel, tin, silver and gold. MCVE’s solutions are ideal for composites, IoT, heating circuits, and medical applications.

Functionalisation of bio-sourced technical fabrics, such as flax combined with PA10-10 resin to manufacture a part by thermocompression dedicated for automotive application.

Copper-based electrical functions are additively produced on coated or uncoated polyester technical fabrics. The fabric will remain flexible.

Printing heating tracks, antennas and sensors on fibreglass reinforcement. The whole assembly is inserted into thermoplastic or thermosetting composites. The robustness of the composite structure is preserved.

CONTACT US

86 rue Lieutenant Colonel DAGNAUX – 57685 AUGNY – France

E-mail : contact@mcve-tech.com

Tél : (+33)6 29 02 56 74

Website : https://www.mcve-tech.com/