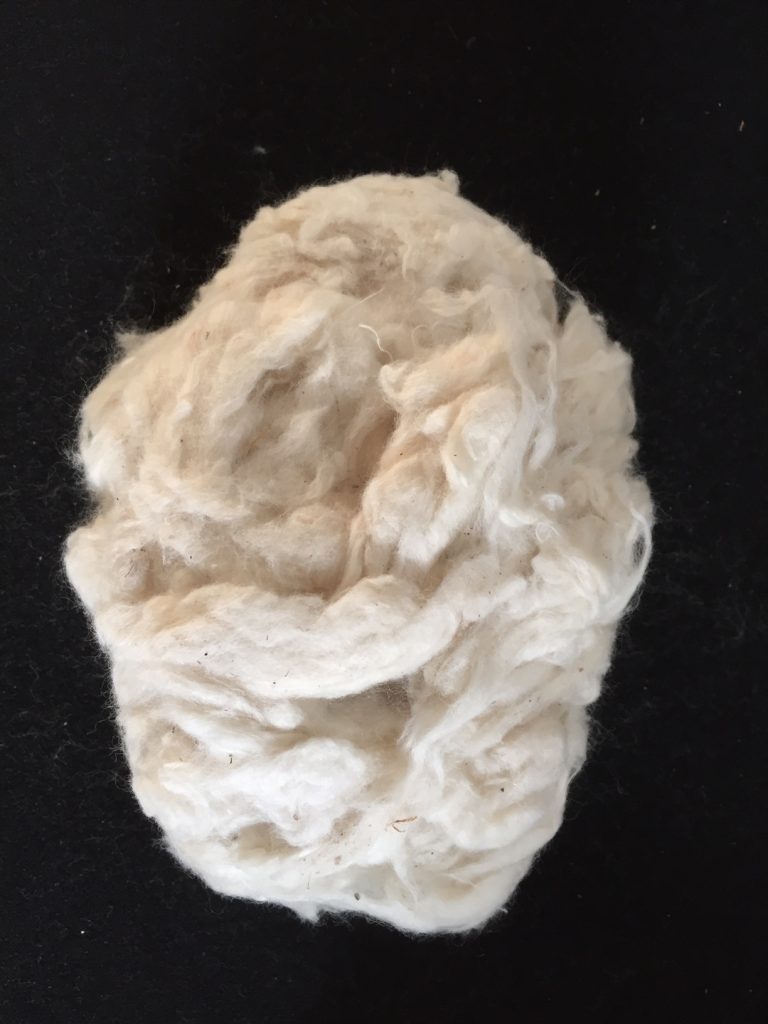

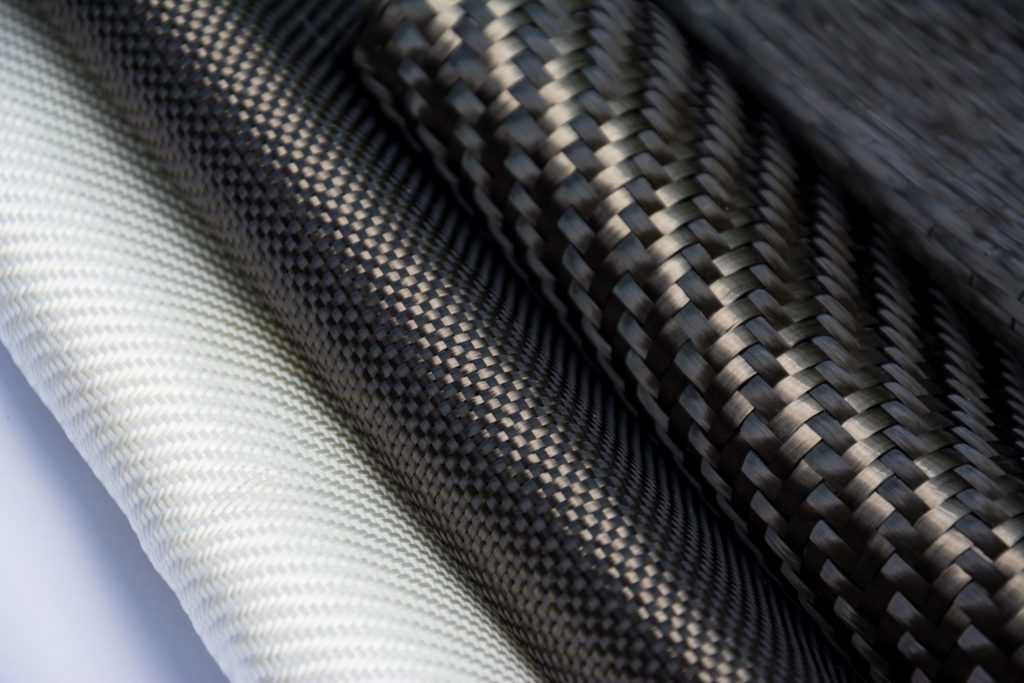

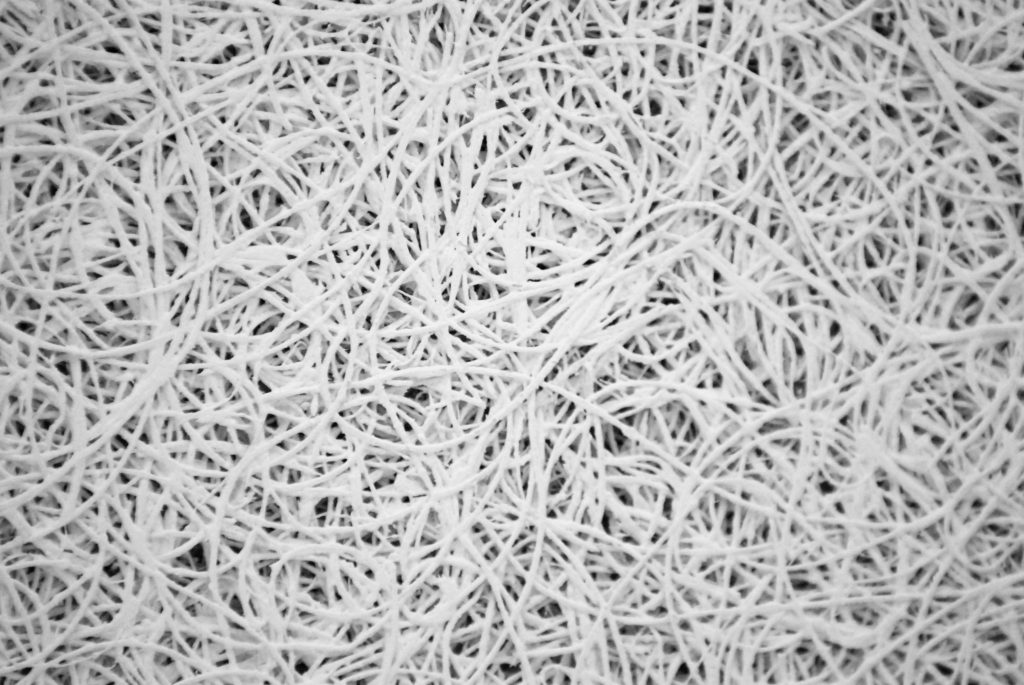

IMATTEC is a French technical spinning company based in the north of France, specializing among other skills, in long-fiber spinning. From raw material to fabrics, our spinning mill develops and produces high-performance technical textiles based on advanced materials (metals, PTFE, aramid, Vectran, polyacrylate IMAT’Fire, PVA, PBO Zylon…) and multiple structures (fibers, single yarns, plied yarns, Multifil, monofil, covered, woven, knitted, fabric, felts, nonwoven…), not hesitating to think outside the box to meet your specific requirements.

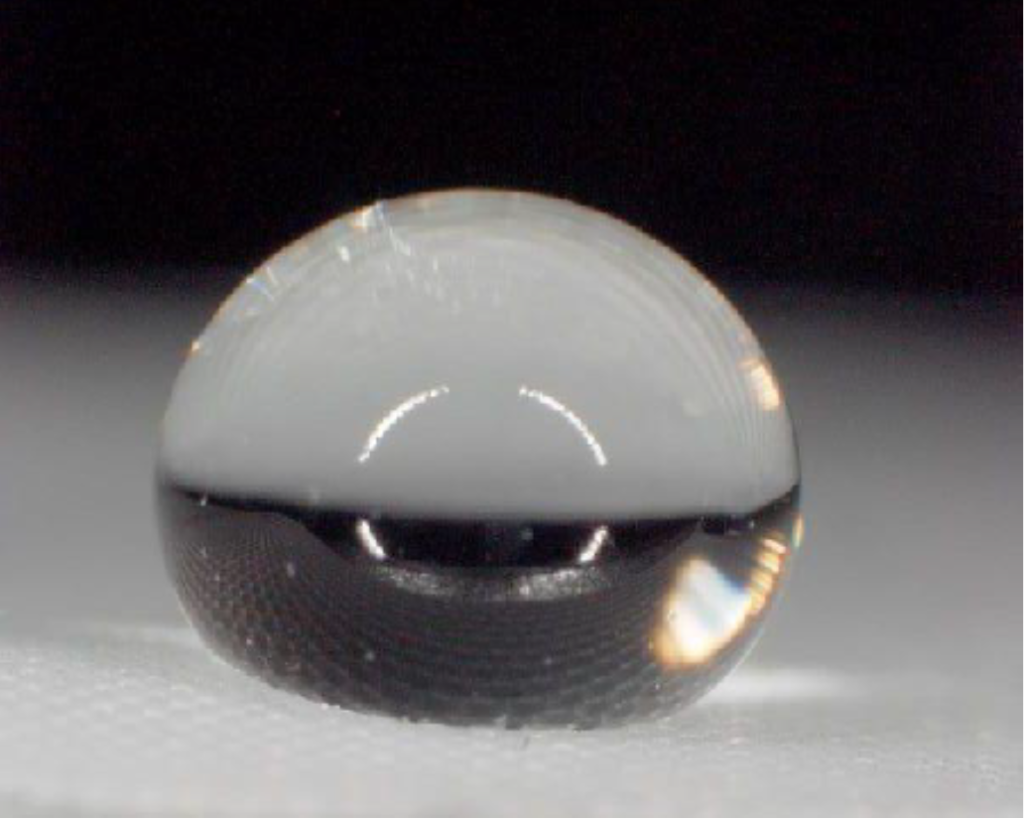

Our company has ISO9001 certification for conception and production. We are able to meet a wide range of requirements : anti-cutting properties, abrasion resistance, anti-perforation, anti-vandalism, cryogenic cold and fire resistance, thermal insulation or thermal transfer, UV resistance and much more.

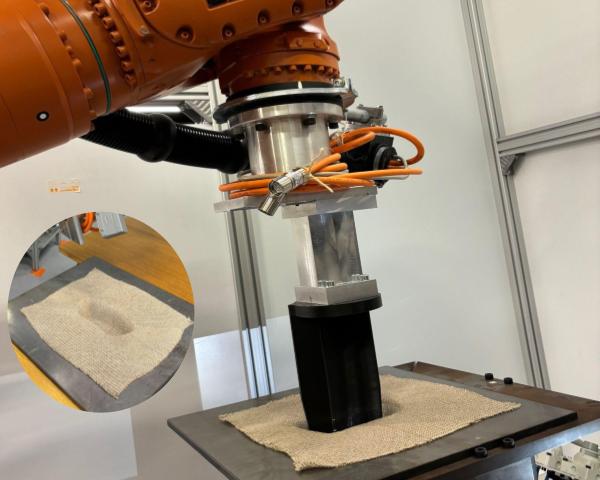

The R&D department adapts to each request, the aim being to meet the needs of each customer. Knitting, dyeing, cutting services, weaving, braiding, IMATTEC develops your custom yarns and fabrics.

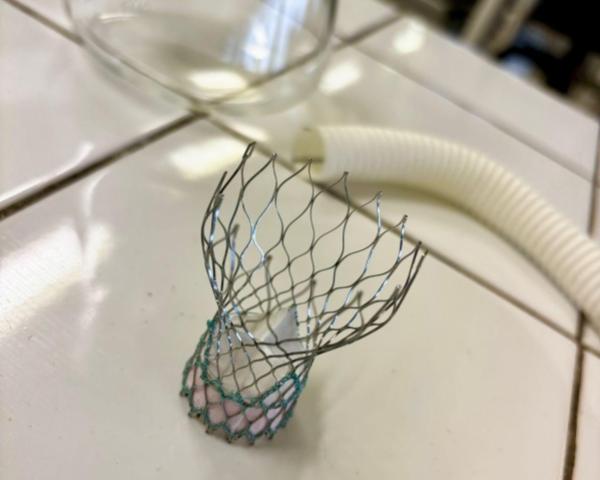

Our current fields of application of our technical textile are vast, covering PPE (personal protective equipment), industry (glass, metal, energy…), sports, filtration, aerospace, defense, automotive, etc. We are involved in a number of regional, national and European collaborative projects in a wide variety of fields, including healthcare, construction, defense, aeronautics and e-textiles / smart textiles…