about us :

Since 1991, Club Textile Integral, network managed by Union des Industries Textile Champagne-Ardenne, supports textile manufactures in their innovation projects, in their search for information, synergies, partners… The Club promotes the textile companies through textile-clothing and technical textiles promotional initiatives. Through “textile-technique.com”, a portal featuring technical data sheets on regional companies, it allows clients to identify products and companies that answers their technical requirements. We also organize CITEXT, the technical textiles business convention that will be held in Troyes on September 24 and 25, 2024.

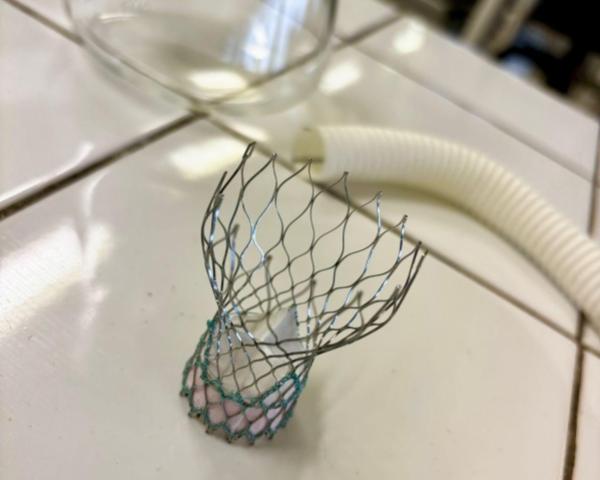

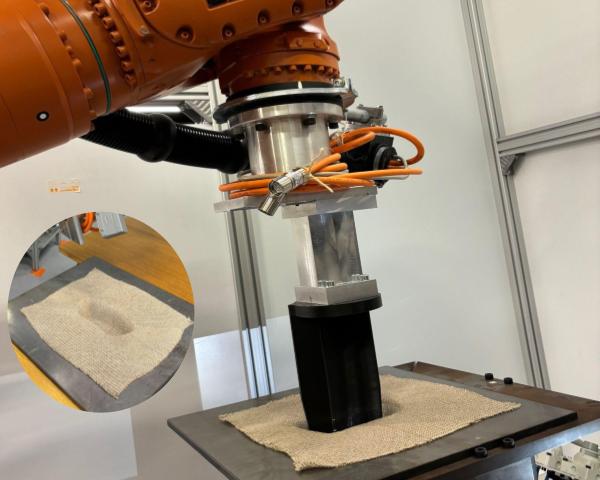

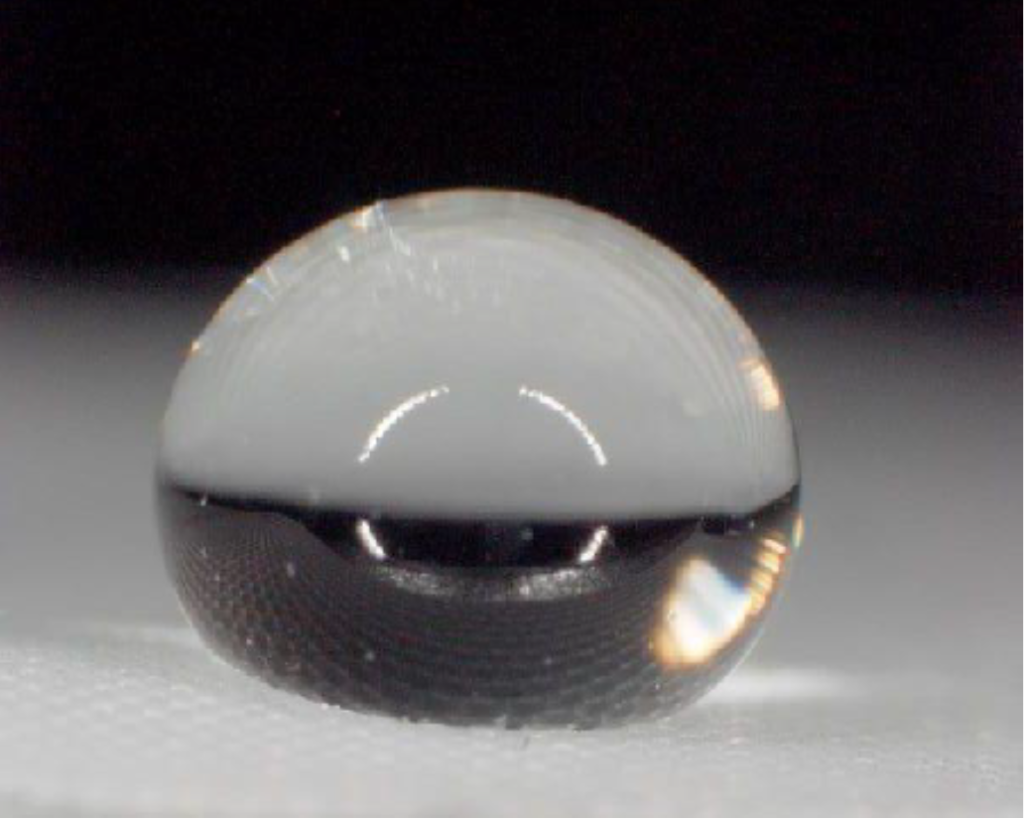

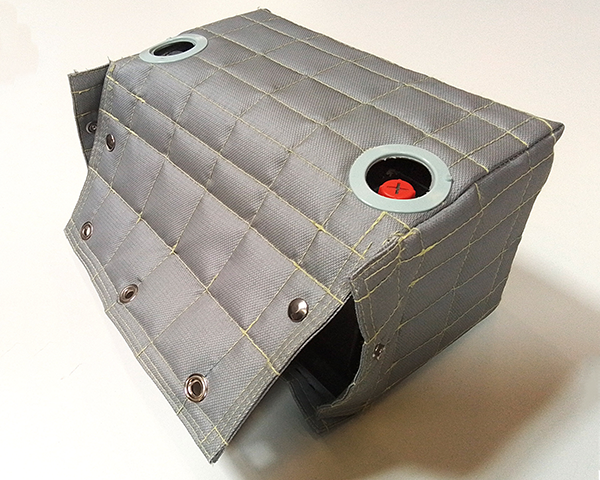

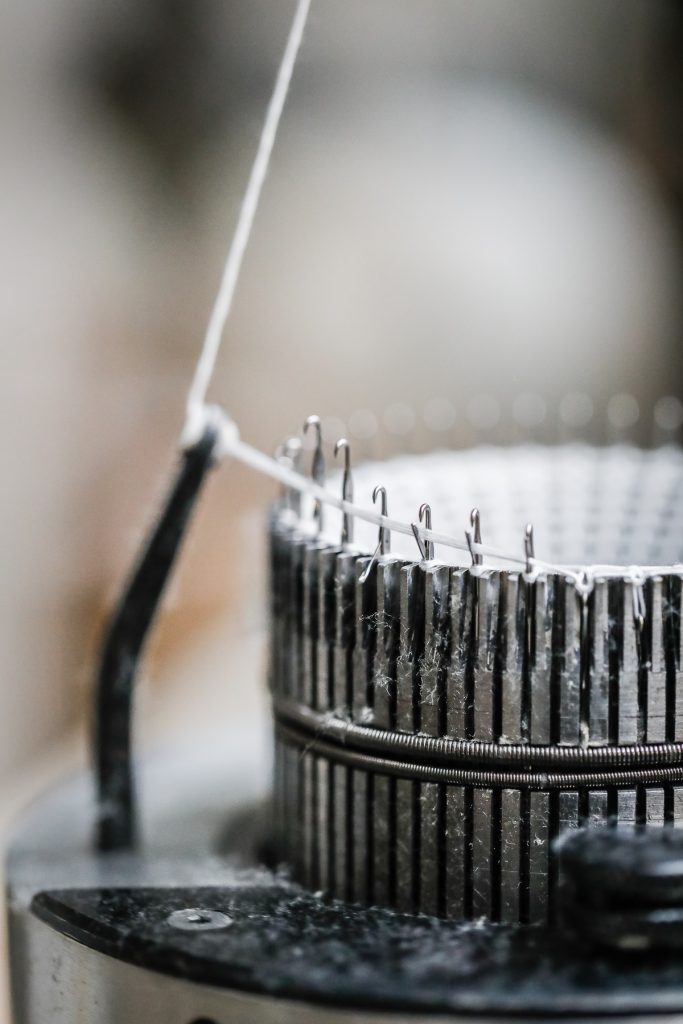

We are located in the east of France, near Troyes city and our manufacturers are specialized in knitwear (knitting, dying, laminating, cutting and sewing).

With this solid network, we empower our members, allowing them to meet startups, to integrate collective projects, to work on industrial and CSR transition.

CONTACT US

1 boulevard Charles Baltet – 10000 Troyes – France

E-mail : s.maucort@uit-ca.fr

Tél. : +33 (0)3 25 43 69 87

https://www.textile-technique.com/