Booth 12.1-E58A

#CoatedFabrics #HeatProtection #FlameProtection #ReleaseCoating #AbrasionResistance #Metallization

about us :

OTEGO is a team of people passionate about their job and committed to improving our customers’ productivity and business development. Our expertise is largely recognized by big international groups and requested for manufacturing issues involving technical fabrics.

OTEGO symbolizes our new identity, focused on our will to protecting people and machines.

The strength of our company is its ability to quickly reply to our customers thanks to our offices in Asia, America, and EMEA. At OTEGO, we speak more than 13 languages such as: English, German, Mandarin, Japanese, French, Spanish, Italian, etc. We stay close to our customers to understand their needs and to provide customized solutions.

Our factory, located near Lyon in France, manufactures coated fabrics using mainly polyurethane, silicone, PVC and metallization. We are a world specialist in Technical Fabrics for applications requiring heat and flame protection, release coatings and abrasion resistance.

Thanks to our know-how in laminating process, we provide a large range of fabrics available everywhere in the world with one motto: Performance.

We export to more than 110 countries, while keeping a local approach on the 5 continents.

Finally, OTEGO is certified EcoVadis Silver proving its social and environmental commitment.

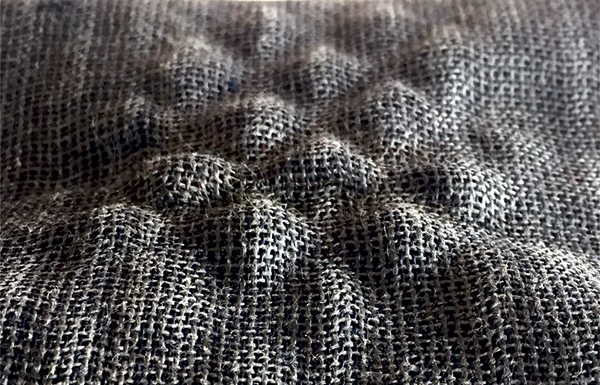

The fabric « 5471 » is an aramid base cloth coated with PU and is used as a flexible bellow cover for laser machines.

It resists to cutting oils, chemicals, hot particles and has a heat resistance of +150°C. It is flame proof, has a great folding memory and a long-life expectancy.

5422 is a polyester/aramid knit coated on 1 side with PU designed for aircraft and helicopter covers.

It is FAR25, ABD0031 and is resisting to skydrol, UV, frost and to temperatures (-50°C to +180°C)

It has Airbus Helicopter, Airbus and Dassault approvals.

FIRESHIELD is a four-layer complex unique on the market, for fire entry and proximity suits. This aramid materials is laminated with aluminium and protects from deadly radiant heat but also against extreme heat. It is certified EN 1486, GA 634 (China) and KFI (Korean).

CONTACT US

465 Rue des Chartinières – 01120 Dagneux – France

E-mail : info@otegotextile.com

Tél : +33 (0)4 37 85 80 00

Website : Otego