about us :

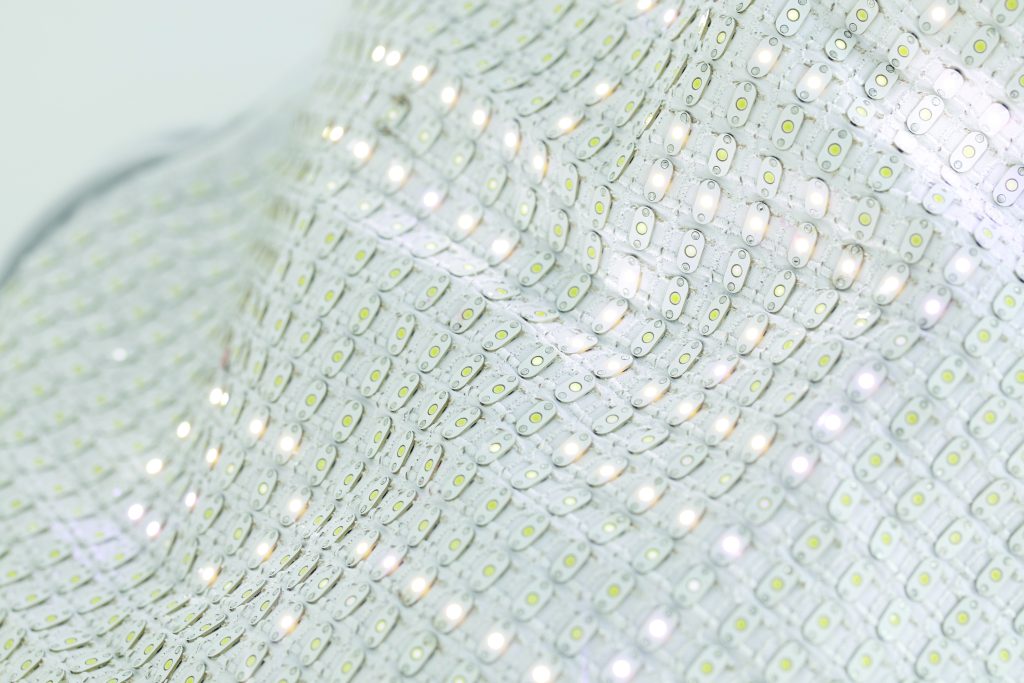

With over 16 years of experience in wearable airbag technology, Alexandre Quarrey, the founder of AQ-Tech, has assembled a muldisciplinary engineering team, positioning the company as a leader in transforming smart textile projects into tangible industrial products, all while staying up-to-date with the latest technology in this field.

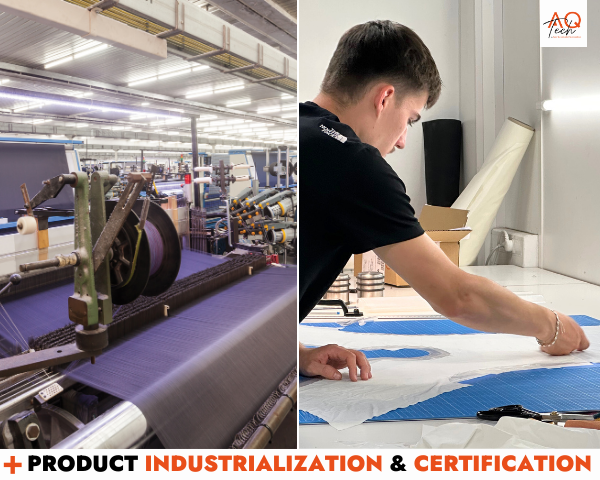

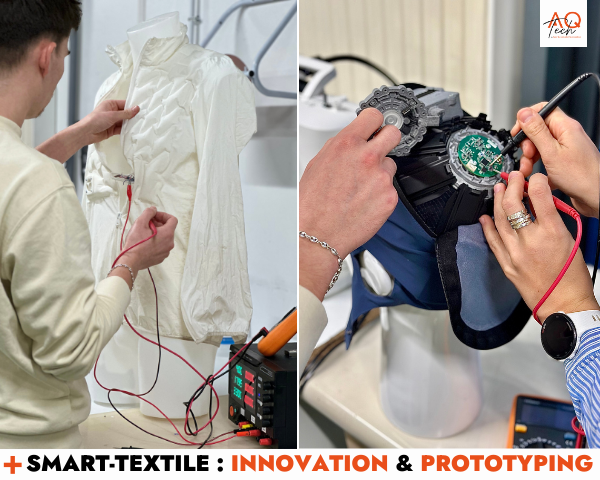

AQ-Tech provides comprehensive guidance throughout the product development journey, focusing on relevant innovation by understanding the specific needs. The process involves then iterative prototyping through early testing to bring ingenious solutions, and customized industrialization—from prototypes to commercialization, covering industrialization, production, and certification.

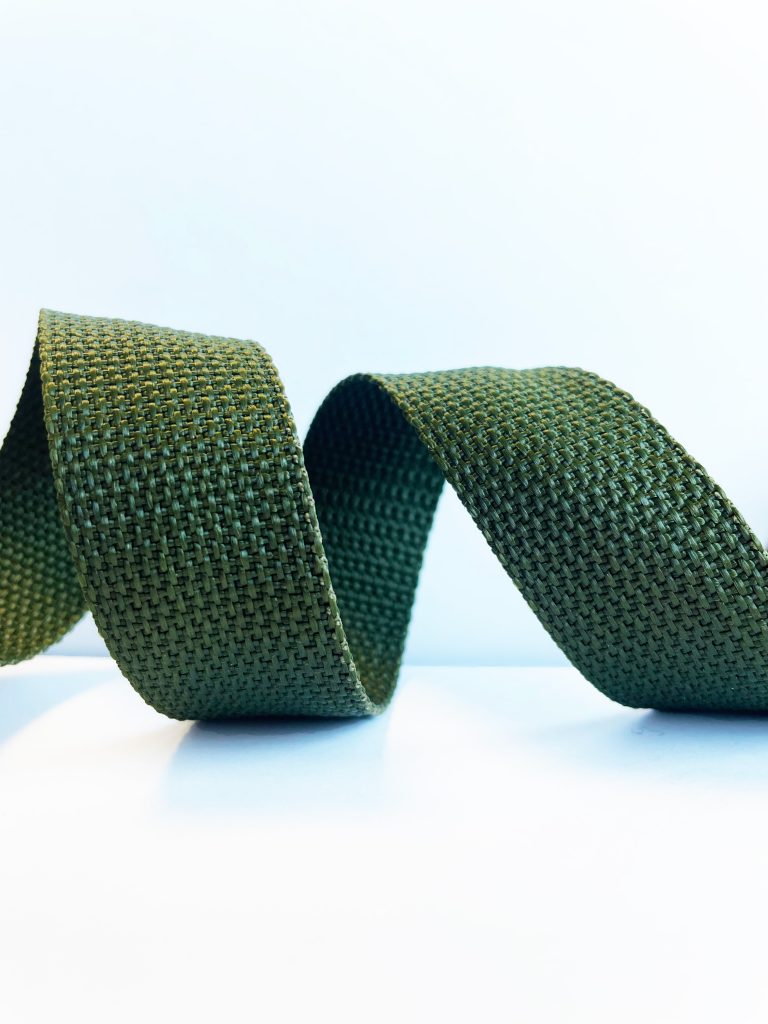

The company’s expertise covers mechanics, electronics, and intelligent textiles including inflatables and airbags. With 450 m2 of workshops and a team of 15 dedicated engineers, AQ-Tech stands as a dynamic force in guiding and executing innovative product development processes for intelligent textiles.

CONTACT US

E-mail : contact@aq-tech.fr

Tél : (+33)4 58 10 52 27 / (+33)6 08 80 70 54

180 route de Prés Rollier – ZAC De Bromines – 74330 Sillingy – France

Website : aq-tech.fr