about us :

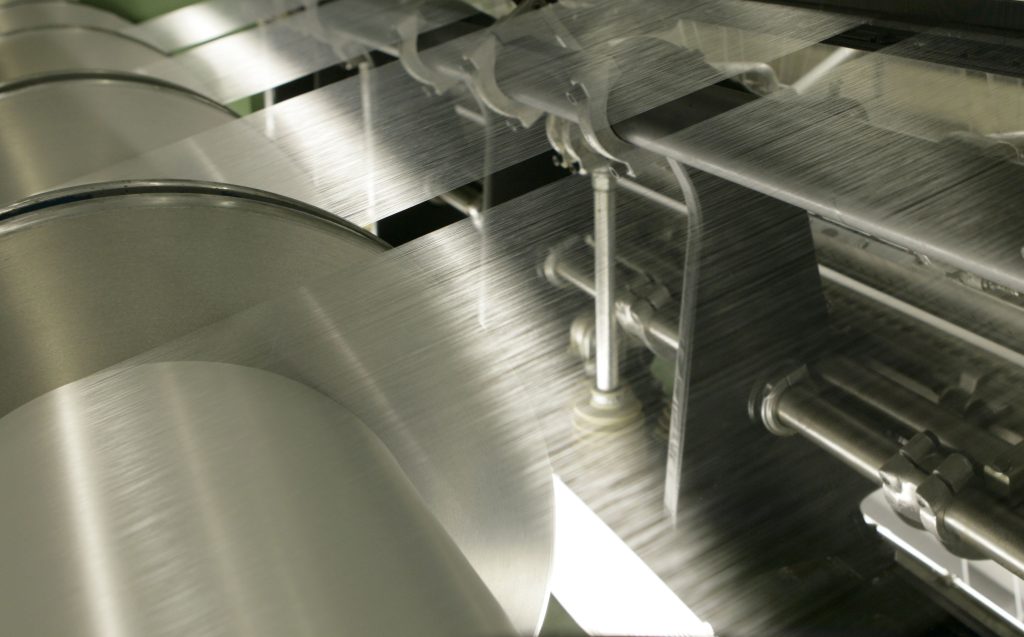

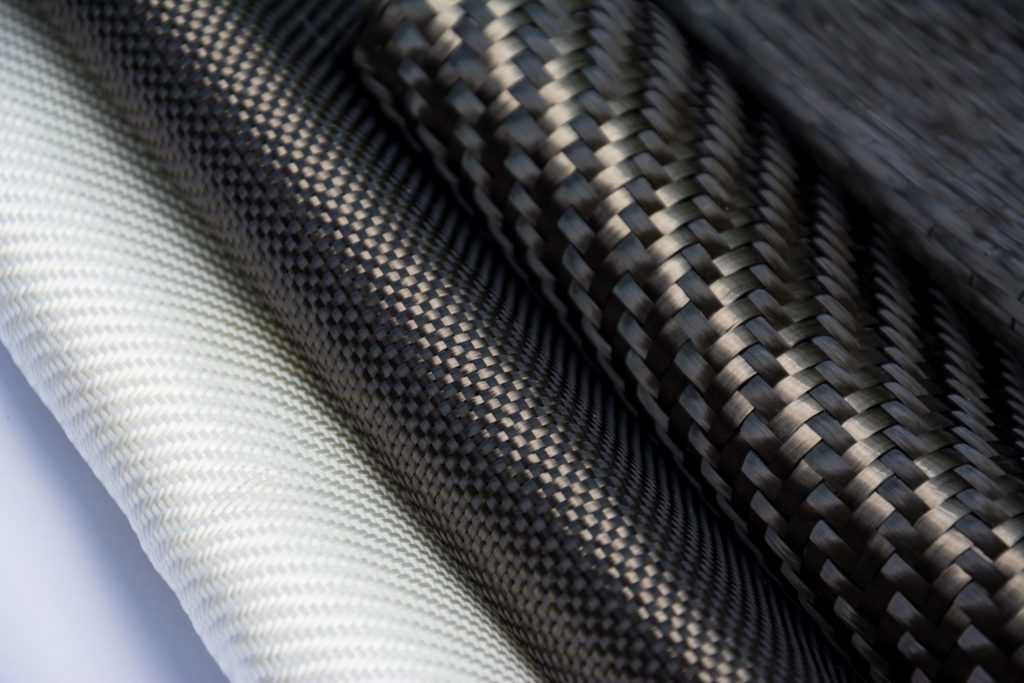

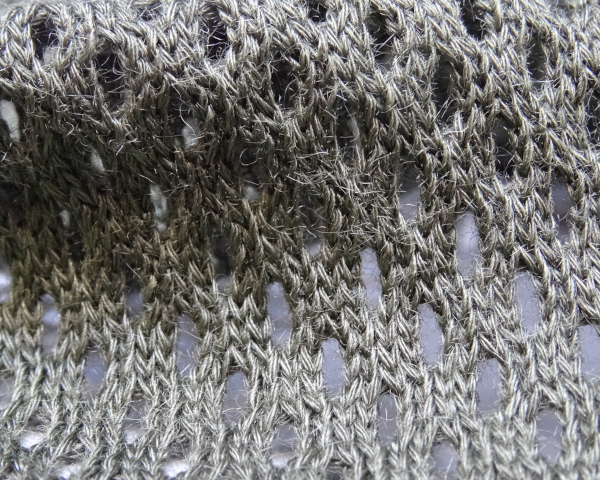

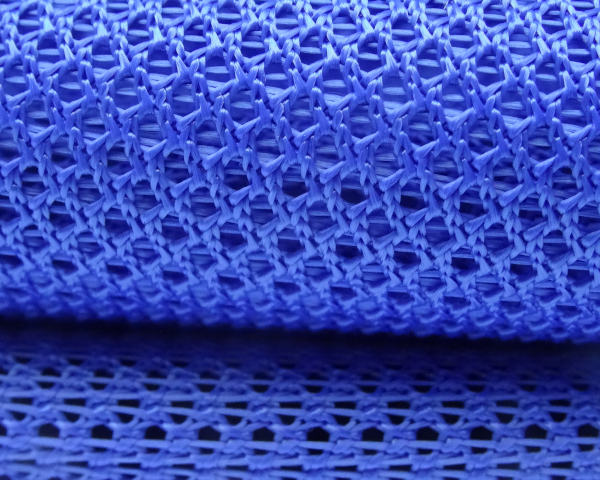

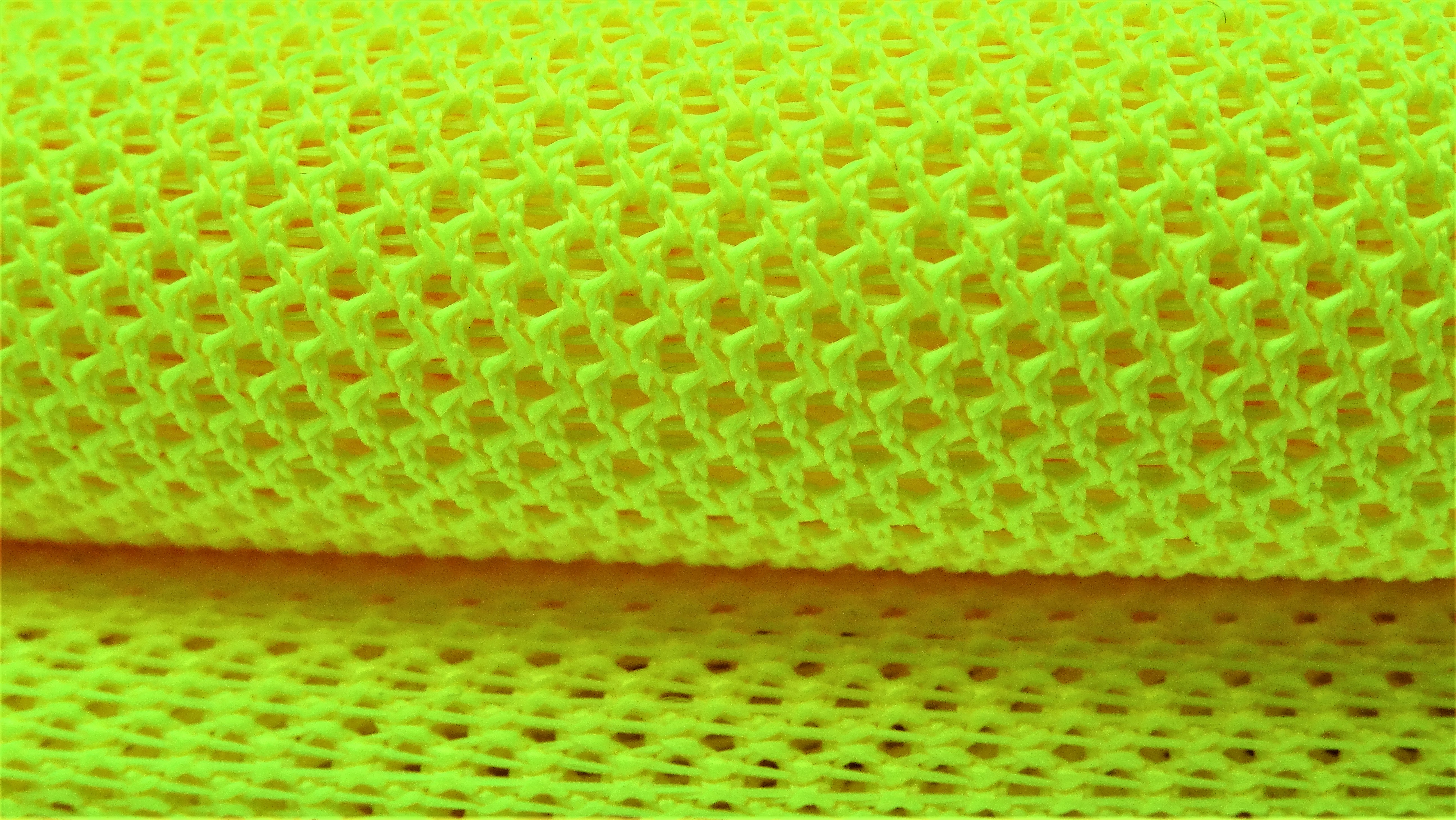

Samuel Roche is a French company, which produces technical webbings for lashing, lifting, harness, aeronautic and for different applications. We have around 70 looms, lot of dyeing machines aa well as testing equipment (drop tower). We are able to different sorts of print on the webbings, cut and roll. We produce shock absorber for fall protection. Majority of our production is in polyester, dyneema, aramid.

We are working with all European countries and USA

Our engineer team can develop new webbings

All of our production is done in the center of France.

We have another activity, endless slings for the construction

CONTACT US

Impasse René Varennes – 42150 La Ricamarie – France

E-mail : c.donofrio@samuelroche.com

Tél. : + 33 (0)4 77 57 24 55/ + 33 (0)6 80 10 88 06

www.samuelroche.com