about us :

Montdor is specialized in the transformation of flexible materials in rolls by giving them technical or aesthetic properties.

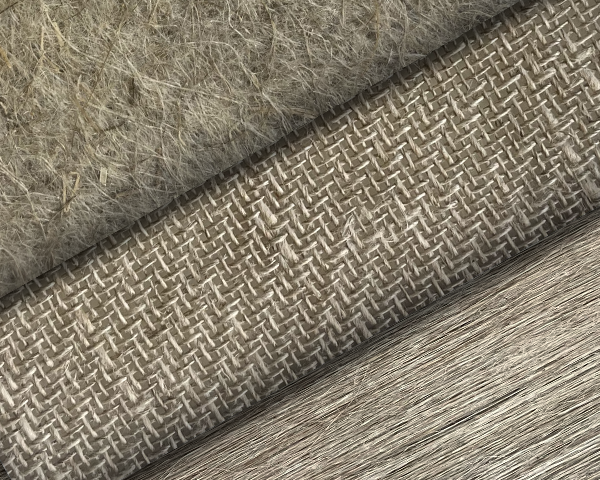

Capacities: Embossing, Deep-embossing, Molding, Bonding by Calendaring and Hot melt, Anti-abrasion /Anti-slip treatment, Transfer Printing, Pleating, Crushing…

We are able to work on several supports such as woven and non-woven, plastic film (PES, PA, PP, PE…), membrane, paper, foam, metal sheet, coated fabric…

Montdor is a well-known player in various sectors such as automotive, composite, luggage industry, sportswear, upholstery, personal protection equipment…

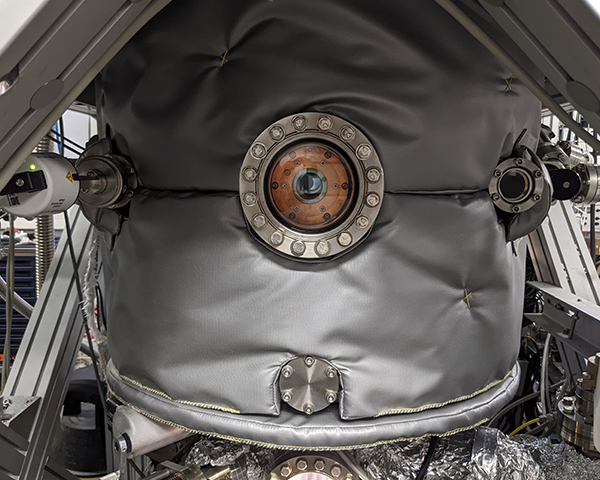

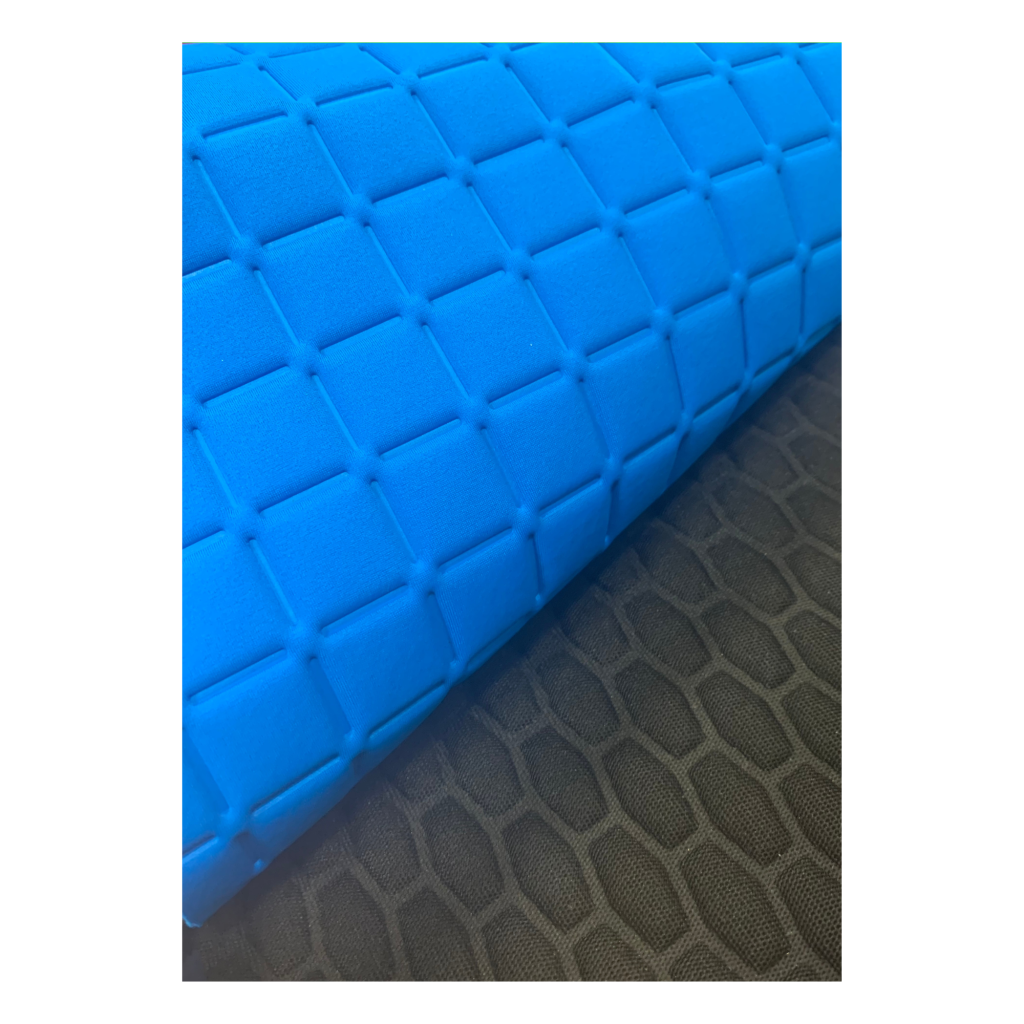

The Molding is a patented technology which consists in a rotative and continuous (foam/non-woven) thermocompression and allow us to obtain important 2D and 3D effects.

The final product is used in automotive industry (seats, headliners, door panels…), transports (bus, trucks…), upholstery (acoustic panels, sofas…), Garments (soft-shell), Wall-coverings…

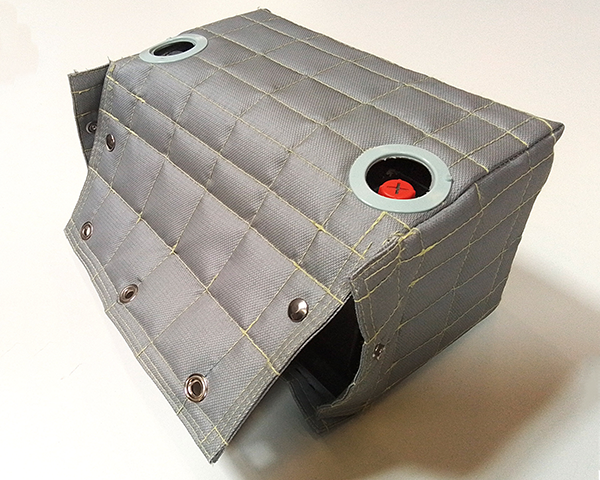

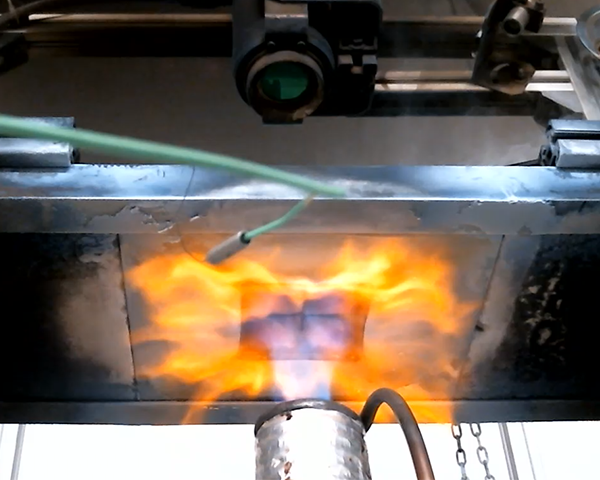

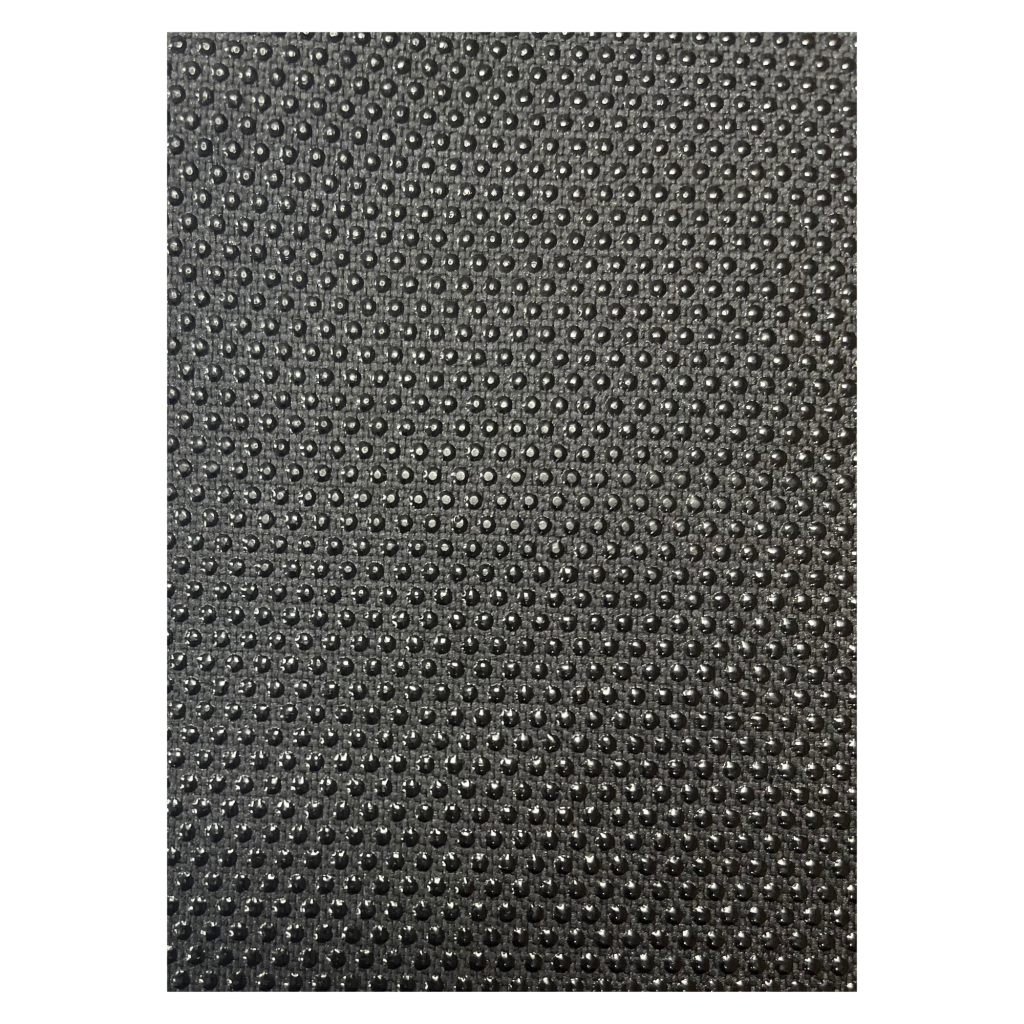

The Dot print is a patented technology which consists in a deposit of high abrasion resistance polymer on the surface of a support.

The Dot print is used in Personal Protection Equipment (elbow and knee pads), Workwear, Military Clothing, Firemen Clothing, Automotive Industry, Sportswear…

We multiply by 5 to 10 the original abrasion performance of the textile.

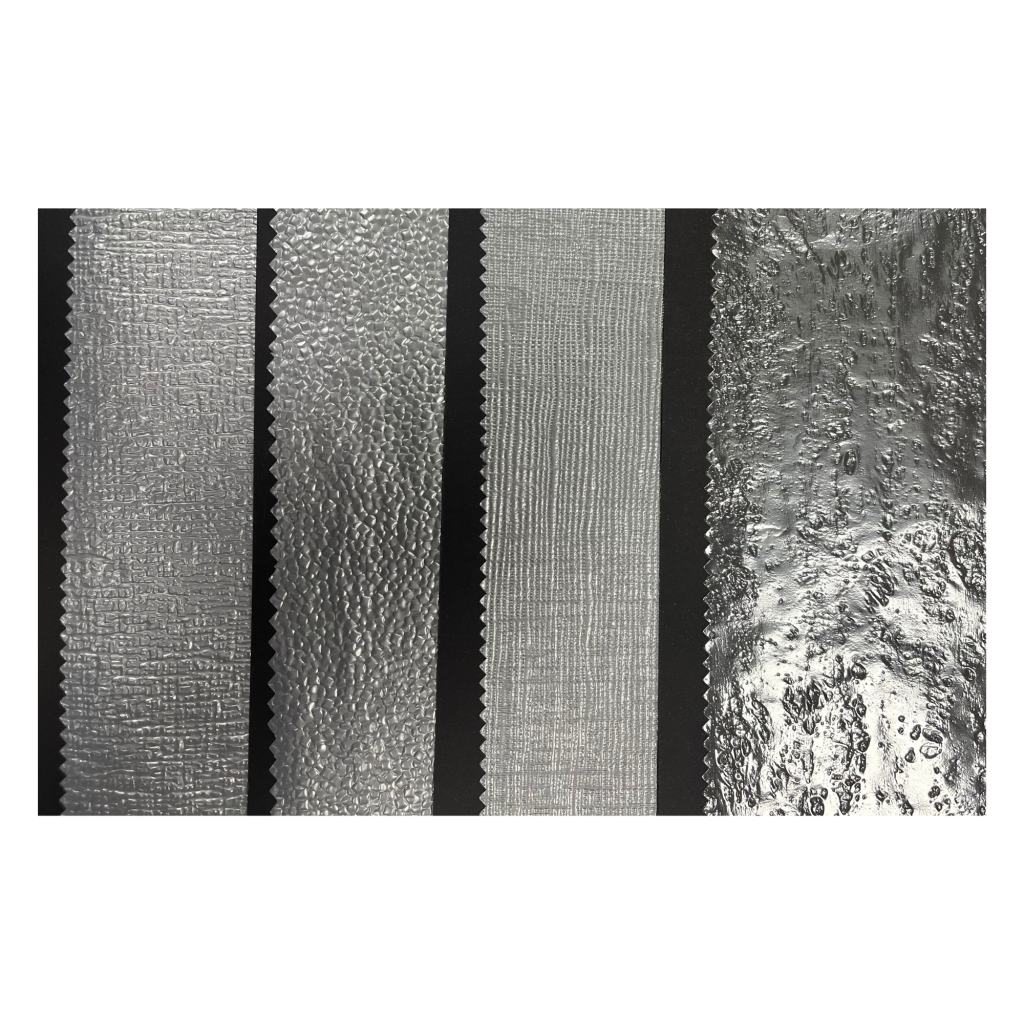

Montdor owns more than 350 cylinders of embossing and are able to work up to 340cm wide.

Montdor is able to work on various supports such as woven, non-woven, knit, dim-out, velvet, sueded fabric, paper, platic films, foam… to give them technical or aesthetic effects.

Embossing is used in Automotive, Furniture, Sportswear, Garments, Composites…

CONTACT US

438 Rue des jonchères – 69730 GENAY – France

E-mail : info@montdor.fr

Tél. : + 33 (0)4 72 08 33 00 / + 33 (0)6 09 67 37 63

https://montdor.fr