#windenergyforecasting #windfarm #renewableenergy #datadrivensolutions #steadyweb #steadysun

about us :

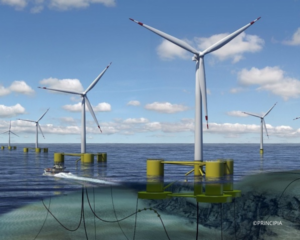

Steadysun offers cutting-edge solutions to accelerate the share of renewable energy in the electricity mix while reducing the costs and risks associated with weather variability.

Our expertise supports all stakeholders in the energy value chain throughout the lifecycle of their projects – grid operators, project developers, energy management system providers, power plant operators, off-grid microgrid operators, energy traders and aggregators, and research institutes.

The company’s core expertise is structured around several key areas:

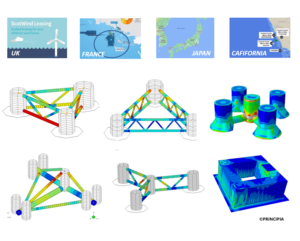

Solar and wind energy forecasting

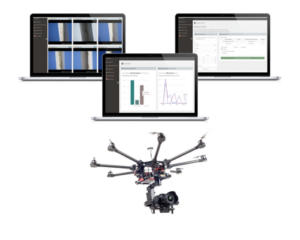

Cloud and atmospheric observation

Consulting on renewable energy and electrical systems

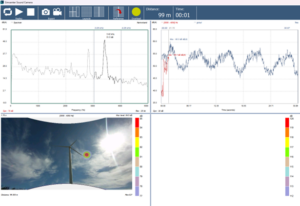

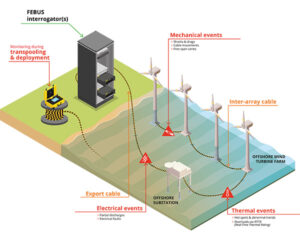

This expertise fuels SteadyWeb, our autonomous data-driven platform designed to optimize the management of your wind energy production by reducing operational risks, improving energy injection, and saving you time.

✅ Accurate Forecasts: Access 15-day production and weather data, updated in real time.

✅ Optimization: Refine forecasts with your plant specifications and real-time data.

✅ Performance: Analyze forecast accuracy and estimate balancing costs.

✅ Easy Integration: Connect our forecasts to your tools via API.

✅ Simplified Management: Manage your assets and adjust your portfolio effortlessly.

✅ Flexible Subscription: Low cost, high earnings

Wind forecasts

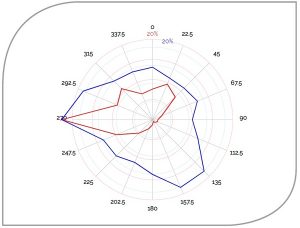

Wind farm production is highly dependent on topography and wind conditions, leading to natural variability. Our forecasting solution enables you to anticipate these fluctuations, reduce costs, manage risks, improve profitability and optimize maintenance.

Features :

-Essential weather parameters: Wind speed, wind direction, wind gusts

-Forecast horizon: Up to 16 days ahead

-Update frequency: Every 5 minutes

-Time granularity: 1 minute

Hindcast datas

Evaluate your forecasts in real conditions using past data. Our solution provides site-specific forecasts simulations, replicating the exact forecasts that would have been generated during a given period under operational conditions. Ideal for project preparation, and performance analysis.

Solar forecast

Accurate solar production forecasts are essential to mitigate risks and optimize energy management. Without reliable forecasts, variability in weather conditions can lead to unnecessary costs and operational issues. Anticipate fluctuations and turn variability into opportunity:

-Producers, maximize revenue.

-Operators, optimize maintenance.

-Traders, manage portfolios confidently.

-Grid operators, integrate solar energy efficiently.

CONTACT US

18 Rue du Lac Saint-André, 73370 Le Bourget-du-Lac

E-mail : contact@steady-sun.com

Tél. : 09 70 75 34 16 / 06 61 22 21 75

Steady-Sun