Booth : Hall B2.EG – 210.9

#HVDC #MVDC #smarthub #powerequipment #powergrids #powercables

about us :

SuperGrid Institute is an Independent Innovation Company based in France. It aims to accelerate the energy transition leveraging the benefits of Direct Current power systems. The massive integration of renewable energy is a great challenge and Offshore Windfarms are key in delivering a substantial part of the power needed (+300 GW by 2050).

SuperGrid institute is working on enabling technologies and services to facilitate the development of such projects. Especially through efficient connections of wind energy to the grid and managing the impact of intermittence and loss inertia.

As a co-founder of Wind power Alliance, we cater to equipment manufacturers and offshore windfarm developers & operators with our expertise, tools and testing facilities, supporting the emergence of innovative system solutions.

We perform feasibility, techno-economic and advanced design studies for wind power collection systems and export power transmission systems.

Grid consulting services

SuperGrid Institute is internationally recognized for its expertise in DC grids. Our experts support your innovative mixed AC/DC grid architecture studies and techno-economic analyses, as well as multi-terminal DC grids control and protection specifications, design and validation.

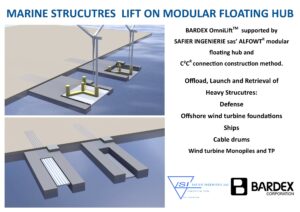

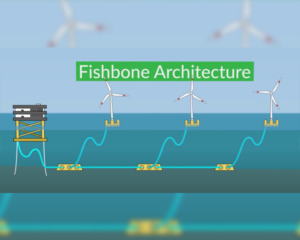

Subsea smart hubs

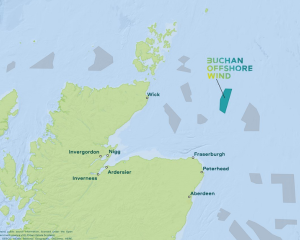

The “Fishbone” architecture is a very promising inter-array collection solution for most forthcoming floating wind farms. It offers higher energy savings at a lower cost & faster installation & intervention times than existing solutions. SuperGrid Institute supports the floating wind industry in the specification, design and validation of subsea smart hubs technologies, the key enabler of fishbone architecture.

OpteaSoft Wind

Our specialised software OpTEAsoft Wind optimises the inter-array design of AC-connected offshore wind farms. It accurately models and assesses the full wind farm connection architecture using widely recognised KPIs, enabling project owners, developers & consultants to make decisions quickly and precisely.

CONTACT US

SuperGrid Institute – 23 rue Cyprian 69100 Villeurbanne

E-mail : paul.vinson@supergrid-institute.com

Tél. : +33 4 28 01 23 23

www.supergrid-institute.com