Hall 6 – B64

#ElectrodesLittingMachine #LithiumiOnBatteries #Batteries #FuelCell #BatteryTechnology #GigaFactory

about us :

One important factor that could affects the Lithium-ion batteries and fuel cells production, is the slitting quality of their components such as coated copper and aluminium foils and PEM (Polymer Electrolyte Membrane also known as Proton Exchange Membrane). The slitting process must be precise, accurate and clean to avoid damaging the coating, the foil and the membrane.

Present on converting equipment manufacturing since 1955, Spoolex gained a strong expertise in slitting and rewinding technology especially for sensitive materials. Our equipment allows to unwind with sensitive tension control a wide web to precisely slit it for producing strips. Then, these strips are carefully rewound in pads with no strip and material alteration, but also with straight wall and burr-free, to ensure a highly productive and consistent production process for optimal performance batteries and fuel cells. Thanks to our integrated R&D and Engineering department, we also offer 4.0 solutions for monitoring and productivity improvement processes, but also, fully or semi-automated solutions for loading/conveying/unloading operations.

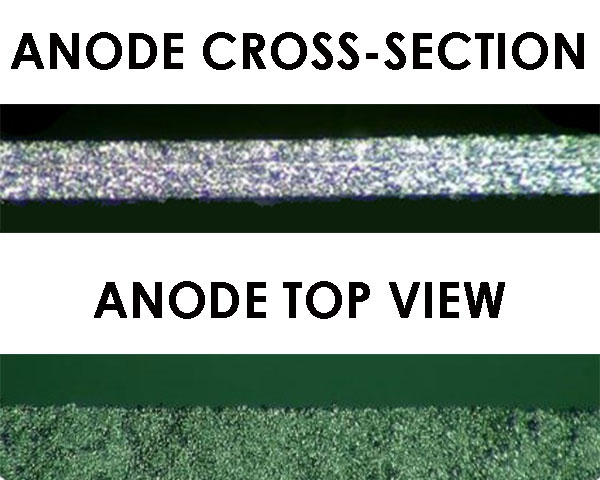

Electrode slitting machine

To transform mother rolls of copper, coated copper and/or aluminium foils, into strip from 70 to 90 mm width and rewind them on individual cores. Our slitting cell is equipped with individual and driven shear knives holders, adjustable wrap angle and special blade shape to reduce burr effect

Fuel cell PEM slitter-rewinder

- To unwind mother roll of PEM membrane,

- Rewind the liner for precise product inspection

- Re-insert the liner before shear cutting

- Rewind the strips on individual core for rolls with consistent tension, clean and straight edges for easy use on downstream processes without damaging the product

Slitting technology

Our experts have developed very accurate individual driven pneumatic shear cutter for Libs:

- Guiding precision +/- 0.1mm

- Slitting tolerance +/- 0.1mm

- Adjustable wrap angle for product incoming and outgoing

- Special blade shape to reduce burr effect

Specific devices for quick cutters alignment and blades lubrification

CONTACT US

ZI du Buisson, 7 rue de la Poudrière – 42230 Roche-la-Molière – France

E-mail : spoolex@spoolex.com

Tél. : +33 (0)4 77 90 72 81 / +33 (0)4 77 90 00 34

www.spoolex.com