#Alumina #WhiteFusedAlumina #WFA #ThermalManagement #TIM #ThermalInterfaceMaterial

about us :

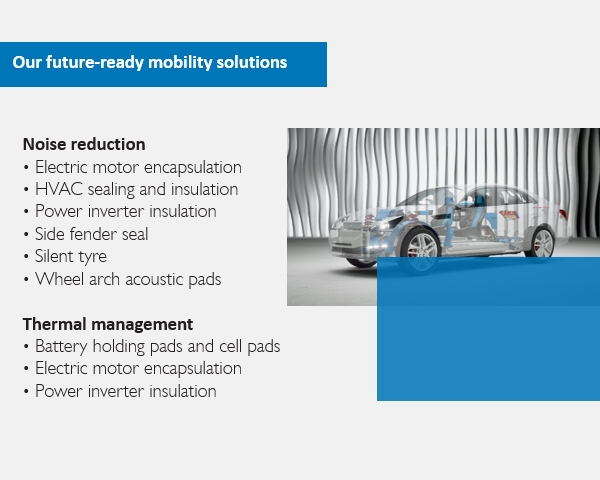

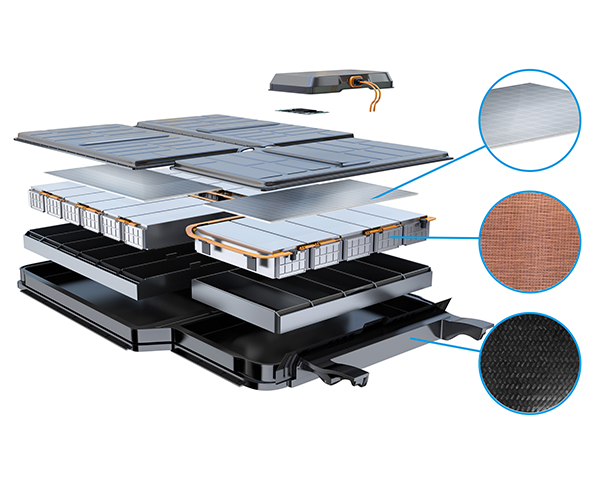

With decades of experience in White Fused Alumina production, NFA controls all the manufacturing steps from fusion to the finished high-purity products in France. We offer high-performance filler solutions to Thermal Interface Materials (TIM) manufacturers worldwide, especially for the EV market.

This WFA grain is obtained by fusion of alumina in an electric arc furnace, followed by a slow solidification process. Its massive shape, along with its monocrystalline structure, bring the right compromise between filling rate, thermal conductivity, and viscosity to our customers in this field.

Custom grain sizes can be developed upon specific requests; please contact our development team for more information and samples at contact@nicheco.com

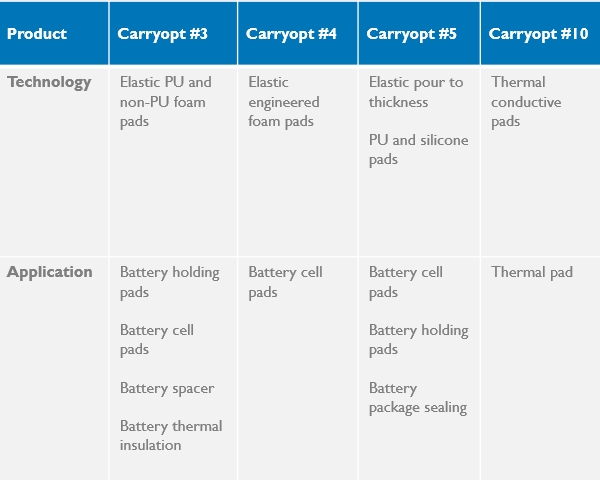

THERMAL-WFA White Fused Alumina:

• Our fillers are designed for multimodal systems, combining fine, medium and coarse particles from 5 to 125µm

• Good packing density and high thermal conductivity

• Low iron and low leachable soda contents

• Right viscosity levels, thanks to a massive blocky shape and a low surface area

• Standard or silane treated versions available

ALTEO and NICHE FUSED ALUMINA join forces to bring ready-to-use solutions to TIM manufacturers, with thermally conductive functional fillers mix solutions up to 3W/(m.K)

The blend of fine calcined TIMAL aluminas with coarser grains from the new THERMAL-WFA fused product line has been optimized to match the specific targets of EVs applications.

OUR ECO-RESPONSIBLE ENGAGEMENTS :

ISO 14001 :2015 and ISO 50001 :2018 certified.

100% produced in France from low carbon energy.

CONTACT US

38 Rue des Fondeurs – 73540 La Bathie – France

E-mail : contact@nicheco.com

Tél. : +33 (0)4 79 31 09 50 / +33 (0)7 69 72 96 45

https://www.nichefusedalumina.com