Hall 9 – 9-B20

#Traceability #QualityControl #ElectrodeManufacturing #Digitalization #Vision #TurnkeySolution

about us :

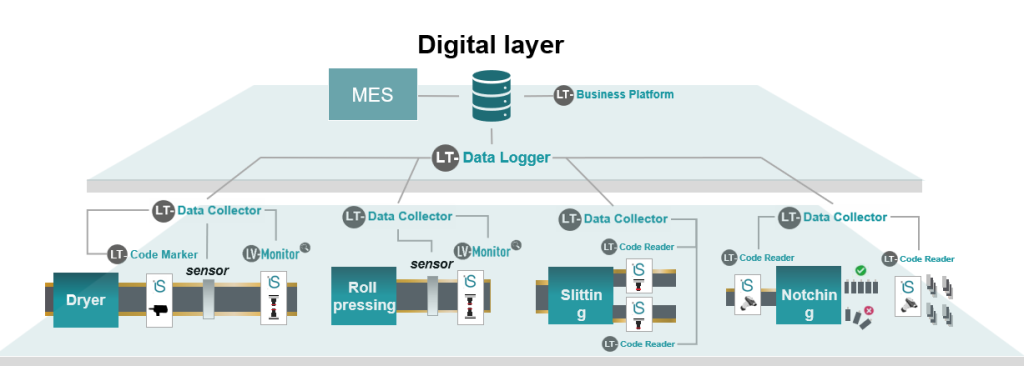

IN-CORE Systèmes designs, manufactures and installs advanced inspection solutions for quality control, traceability and digitalization integrated in all processing steps of the LI-Ions batteries electrodes. Involved in the battery inspection since 2005, IN-CORE has developed several tools to control the quality of the electrodes.

IN-CORE’s solution, installed on other production processes controls the coating width after pressing, the quality of the slits on the slitting machine, the position of the layers on the stacking machine, the quality of the separator on the manufacturing process.

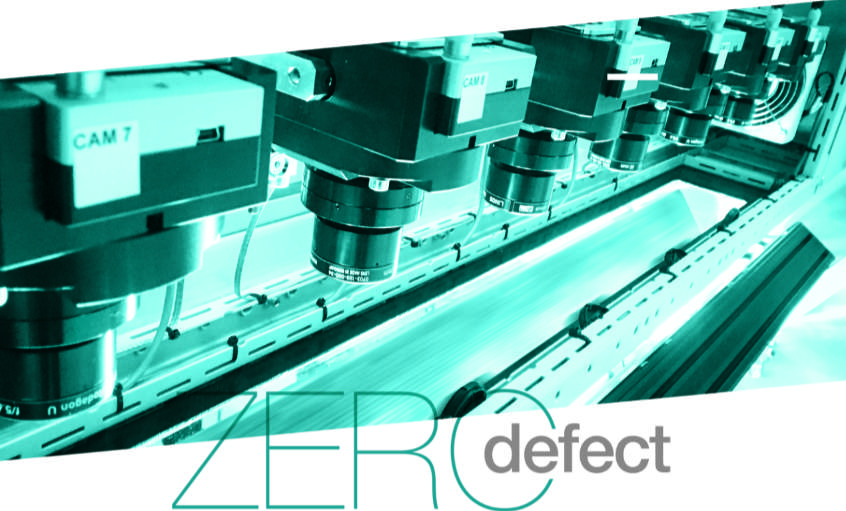

LineaVision:

The quality inspection LineaVision, based on high accurate line sensors, controls 100% of the electrode’ surface on both sides and checks the product compliance with quality request. During the electrode manufacturing, the most important is to check very precisely all geometrical parameters which influence directly the electrodes performances.

2d marking system:

In-CORE Electrode sheet code marking system engraves the unique 2D code for better traceability.

LineaTrack:

LineaTrack, installed in the coating line, is IN-CORE’ tool to serialize each individual electrode whatever the coating pattern

This is what we call full digitalization solution perfectly customized to the electrodes manufacturing level.

OUR ECO-RESPONSIBLE ENGAGEMENTS :

ISO14001 : in evaluation of implementation

CONTACT US

10 Rue Ampère – 69680 Chassieu – France

E-mail : info@incore-systemes.fr

Tél. : +33 (0)6 14 35 20 98

www.incore-systemes.fr