about us :

French-based company, established for over 40 years, Interep is the European Leader in cellular foam engineering & manufacturing, with 140 employees. Over our history we have also strengthened our positions with a solid partnership in China to provide our customers with a worldwide offer.

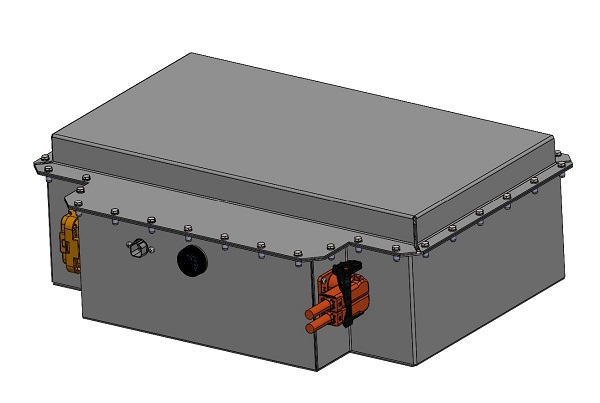

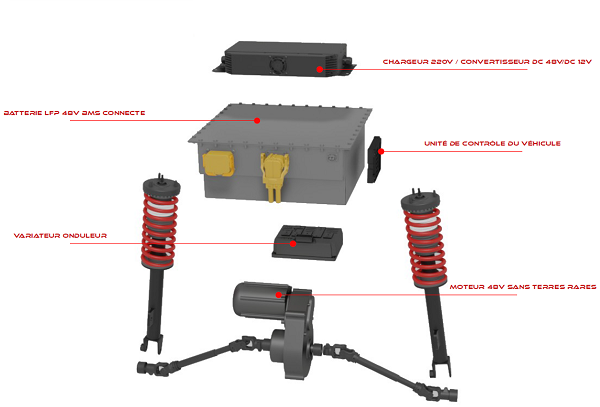

Having huge industrial capacities and a wide R&D knowledge in elastomers, our portfolio of products addresses various sectors. We have strong positions in the automotive & industry, being well-recognized for the reliability of our products, especially for their excellent properties for sealing and dampening. Temperature, fire & chemical resistance as well as shock absorption are highly requested performances for which our sales team and our lab can offer expertise at service of best-in-class customers. Since 2021, we are committed to a virtuous transition while continuously reducing our carbon footprint. A key motivation in our corporate durability project : IN-LIF²E is to become a strong player for e-mobility and propose to the market cutting edge solutions.

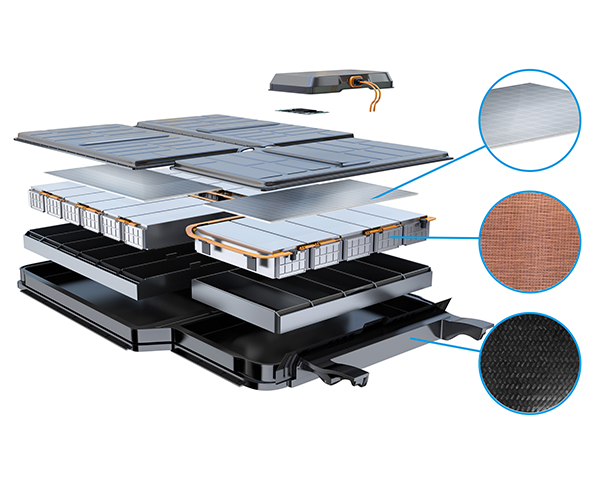

We offer over 50 rubber foam grades, engineered with 6 elastomers (EPDM, CR , NR, SBR, NBR, EVM). We are a key partner to answer most of demanding needs : sealing, cushioning and battery pack assembly. In addition, we can rely on a large network of converters to propose tailor made solutions.

Our laboratories consist in 10 elastomers experts and cutting-edge equipment. We are at your service to develop the solution fitting your specific needs, if you cannot find it in our series offer.

Characterize, formulate, and test any new foams is possible, thanks to our team expertise and tooling.

Let’s discover some of our products, enhanced for :

– Fire resistance: CNA – CIG3

– Shock absorption: MicroSHOCK Range

– First insights in our capability to manufacture thermal conductive material

OUR ECO-RESPONSIBLE ENGAGEMENTS :

At INTEREP, we recognize the urgent need to address environmental challenges. To mitigate our impact, we have developed since 2021 IN-LIF²E, our corporate project leaded by comprehensive strategies to reduce energy consumption and improve waste management across our entire manufacturing process.

Having innovation at the core of our company’s sustainability commitment, we consistently invest in research and development to discover and implement cutting-edge technologies that minimize environmental impact. By embracing a culture of innovation, we aim to set industry standards, inspiring positive change and influencing others to adopt sustainable practices.

In 2023, we have collected data and emissions factors. This entails incorporating impact at all levels of our processes, meaning summing up the emissions from all relevant sources, and accurately measuring scopes 1, 2 and starting scope 3 evaluation. Next step will be to present the results in a clear and transparent manner, while describing all associated assumptions.

In 2023, our products portfolio already includes sustainable EPDM and NR foams.

We are now actively working to build in 2024 our products “Carbon ID card”. This will involve creating a carbon footprint report that outlines the emissions by scope, identifies key drivers, and sets the stage for future reduction strategies.

Thanks to this approach, we have been awarded by our professional trade union as innovative company and entered in 2022 the “Coq Vert” Community.