Hall 9 – 9-B30

#EMIShielding #HarnessesProtection #FlexibleConnectionBraid

about us :

We are an international company based in France, Texprotec produces cable and duct protection sheaths, as well as conduction braids.

Through our various companies and the handing down of know-how over six generations, Texprotec has acquired a wide expertise in the techniques of braiding, weaving, and knitting textile and metal yarns.

A visionary company, Texprotec pursues an aggressive innovation policy and has positioned itself in such niche markets as the automotive, aerospace, rail, electronics, medical and military sectors.

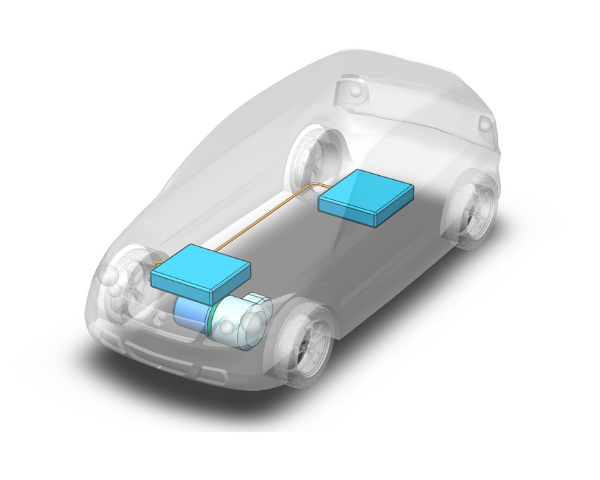

Faced with the exponential development of mobility, the group Texprotec has developed a brand called Emiprotec.

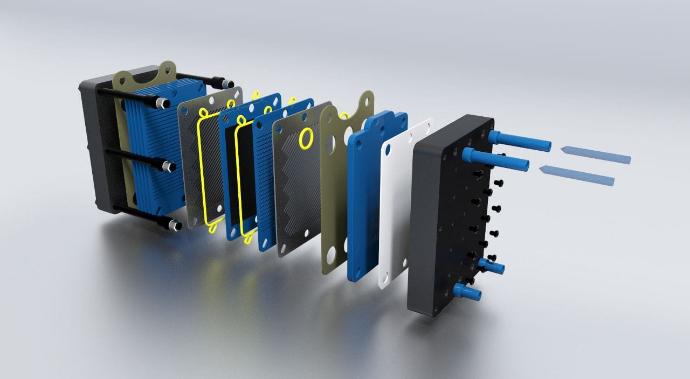

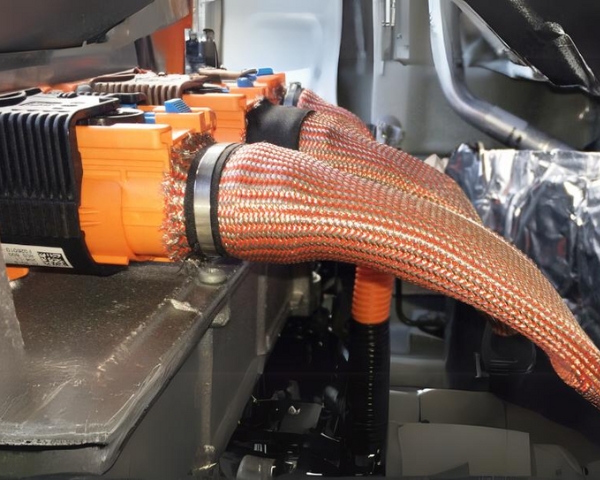

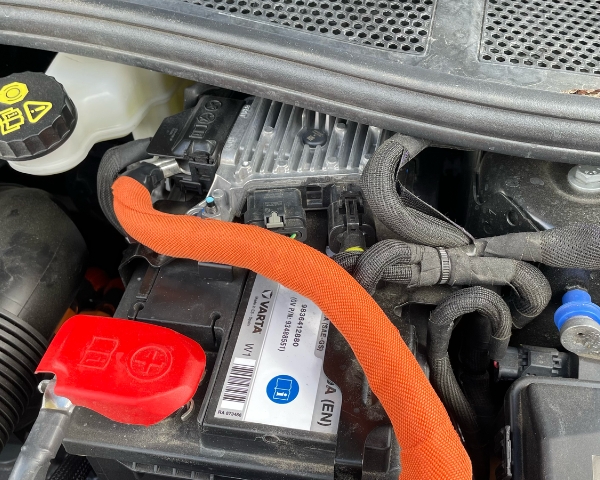

Emiprotec is a range of braided sheaths with electromagnetic shielding, described as peripheral.

Emiprotec’s sheaths not only manage to protect the passengers in vehicles with large interference emissions, but also assure the smooth operation of the more sensitive electronic devices of the vehicle (such as the sat nav, the radio, electronic systemes, sensors).

With this specific range, Texprotec demonstrates its unique savoir-faire and its innovation strategy in the technological field of shielding in electromagnetic areas, as well as its capacity to develop solutions adapted to the needs of manufacturers and equipment suppliers.

We are based in France with 3 subsidiaries, in Mexico with a facility based in Leon, and a Sale office based in Shanghai.

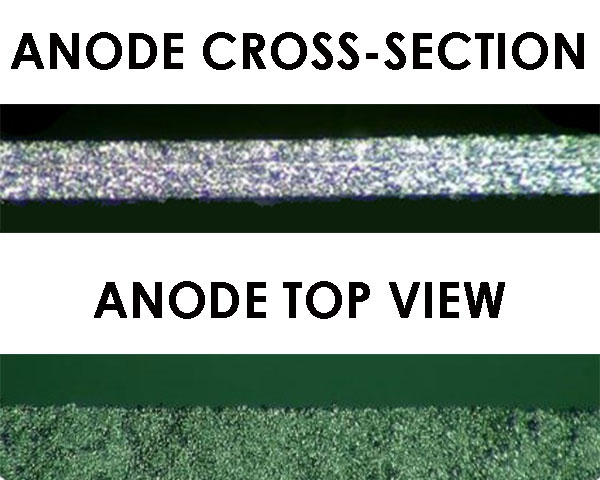

The TISAFLEX EMI-PHY shielding sheath was invented and patented to protect humans and electronic equipment against electromagnetic waves emitted by power cables in hybrid and electric vehicles. It offers excellent resistance to abrasion both inside and out. It is easy to install, even in small spaces.

Texprotec can support OEM and Tier One for the development of EMI Shielding adapted to the vehicle environment. We developed our own software to define the mechanical model. Our laboratory could validate the prototype calculated and launch the serial product.

Texprotec have a long tradition for textile protection sleeve. Our products are validated by OEM to protect harnesses or hoses for automotive application. Our R&D department could develop specific product according to the technical specification of our customers.

OUR ECO-RESPONSIBLE ENGAGEMENTS :

ISO 14001 – ECOVADIS

CONTACT US

E-mail : s.mony@texprotec.com

Tél. : +33 (0)4 73 82 45 75 | +33 (0)6 49 30 85 22

www.texprotec.com