Hall 9 – Booth 9-B20

#Lithium #Battery #V #Powertech #Storage #Energy

about us :

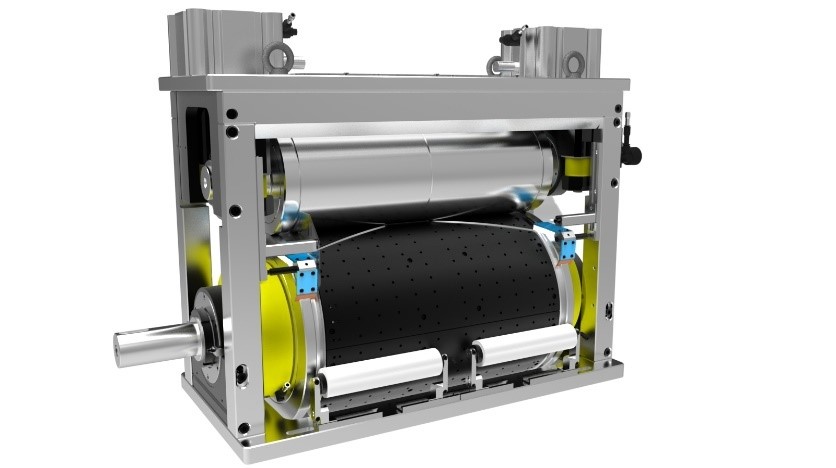

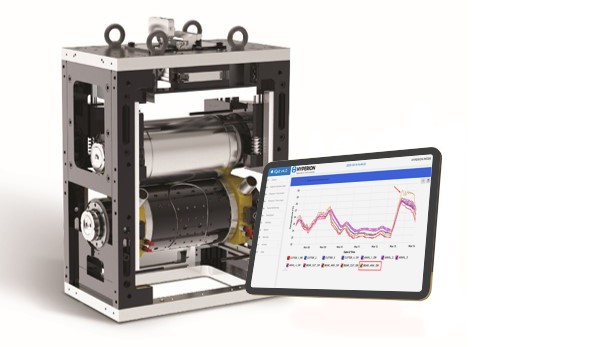

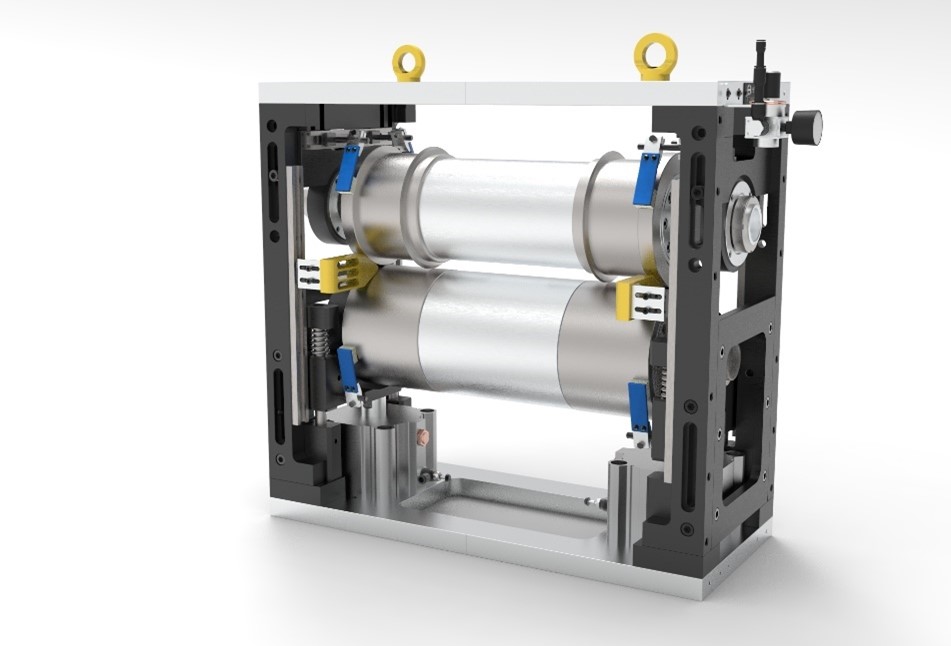

With over ten years’ experience, we design, develop and market lithium-ion batteries for professional energy storage. Our scalable solutions are high-performance and carefully engineered, making them suitable for a wide range of applications such as telecoms, robotics, automotive, marine and aerospace.

At PowerTech Systems, we offer reliable and innovative products designed to maximise energy density, improve safety and extend system life.

Innovation is at the heart of our business. We work with industrial partners and research institutes to stay at the forefront of technological advances. We are also committed to sustainable, environmentally friendly practices, promoting the use of clean energy and adopting environmentally-friendly manufacturing processes.

With a global presence and a solid reputation, we strive to provide reliable and innovative solutions for a greener, more sustainable future. At PowerTech Systems, we believe in a future where clean and efficient energy is accessible to everyone.

Our high-performance solutions are suitable for a wide range of applications, such as:

ENERGY STORAGE

Traction and E-mobility :

OUR ECO-RESPONSIBLE ENGAGEMENTS :

ISO 9001, UN38 and Ofshore marine certified, we are proud to promote the use of clean energy and to be part of a greener way of consuming.

CONTACT US

6 bd Georges-Marie Guynemer – Bat. A1 – 78210 Saint-Cyr l’Ecole – FRANCE

E-mail : contact@powertechsystems.eu

Tél. : +33 (0)1 85 40 09 70 / +33 (0)1 85 40 16 60

Solutions de stockage d’énergie électrique et de batteries Lithium-Ion – PowerTech Systems