Hall 9 – 9-B30

#SolutionThermoplastiques #FluidManagement #BusBar #Housing #Multi-Injection #SurmoulagePressfit

about us :

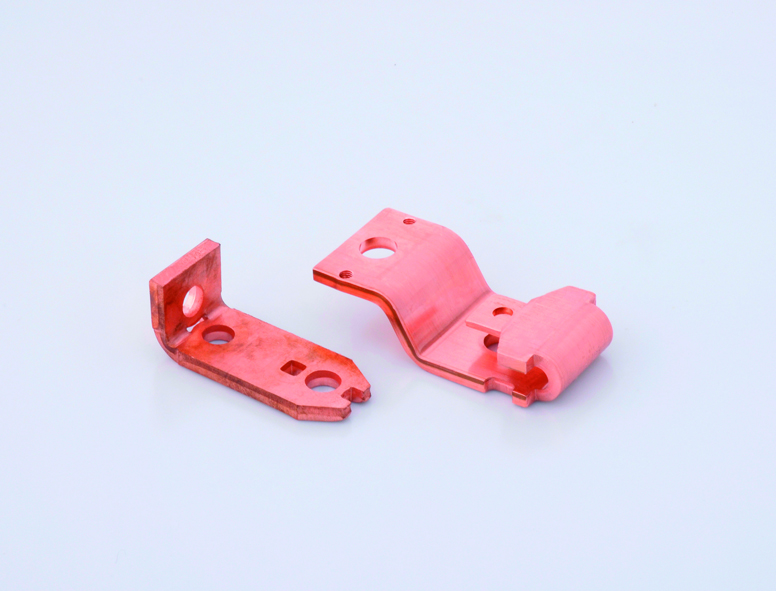

MIHB, a specialist in the transformation of thermoplastic materials, is a recognized expert in the design, industrialization and production of technical parts with high added value, from motion transmission, fluid management, appearance parts, electrical connections and much more.

MIHB supports you from the choice of plastic materials to product design, tooling development and robotic expertise. A transversal approach that also revolves around our Design Office and our know-how in rheology, metrology, assembly and logistics.

MIHB integrates advanced technologies in its workshop:

– Multi-material injection (bi injection, tri injection, quadri injection)

– IMA – overmoulding of two hollow bodies in the mold during the same cycle

– Over-molding

– Extrusion

– Injection blow molding

– IMF – In Mold Forming

For more than 50 years, MIHB has developed a real expertise in the plastic industry. We provide a full line approach to make your project a success. MIHB creates trust, focus on communication, reactivity and build a long-term partnership with its customer.

MIHB supports its customer by providing solutions for thermoplastic parts/products as bellow:

- The right choice of raw material

- Co-design

- Technical feasability

- Industrial design

- Rheology

- Metrology

- Prototypes

We support you in creating infinite combinations of thermoplastic materials (function, cost, characteristic) that will ensure the quality of your plastic productions (plastic gears, connectors, pictograms, etc).

Our teams master the technologies of:

- single, bi, tri ou quadri material injection

- In Mold Assembly

- In Mold Labelling

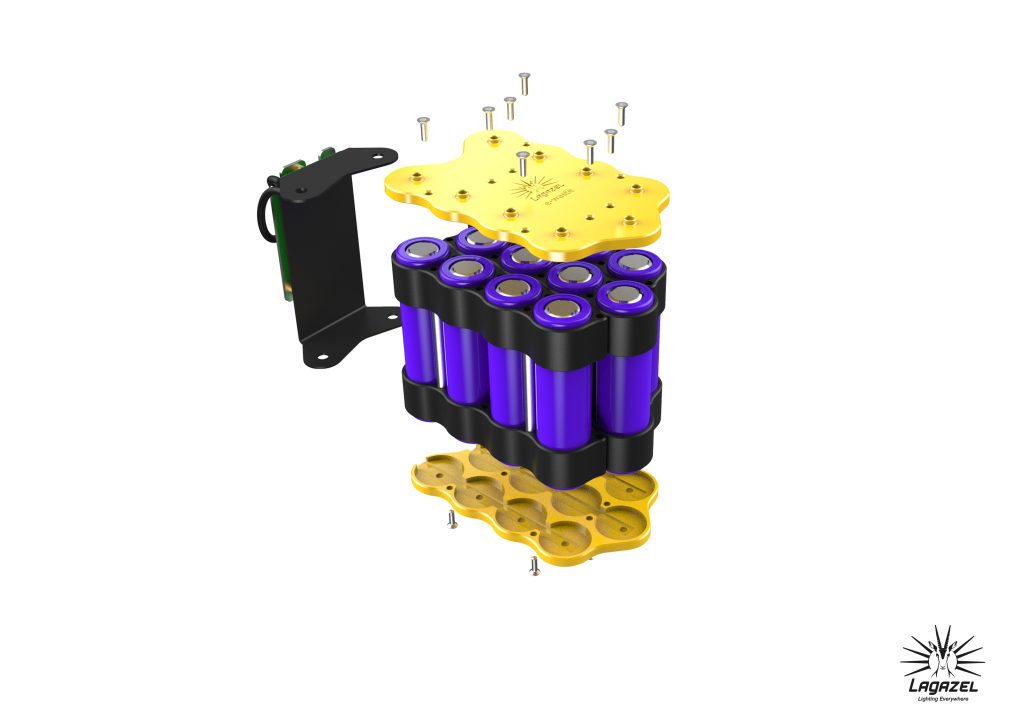

- Inserts/busbar/magnet overmolding

MIHB is more than an injector, we can also assemble parts.

Our teams design and create:

- Manual assembly solutions,

- Semi-automatic,

- Fully automatic,

- Ultrasonic and hot-edge welding.

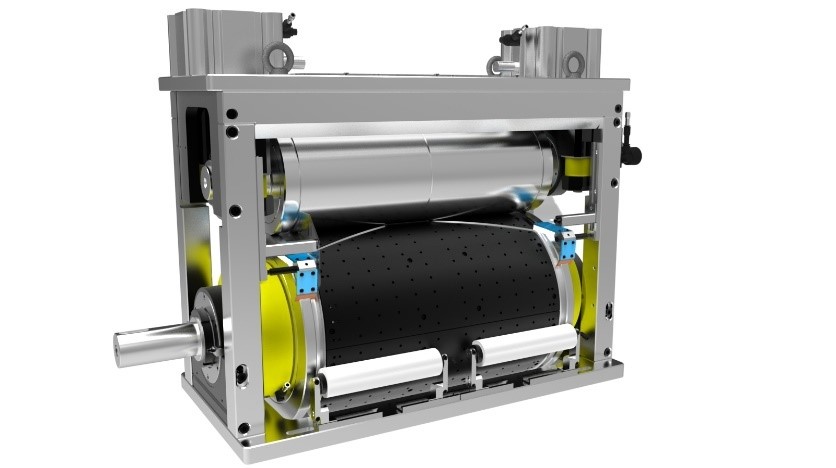

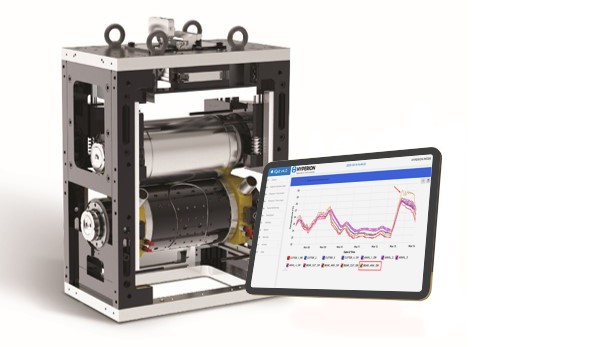

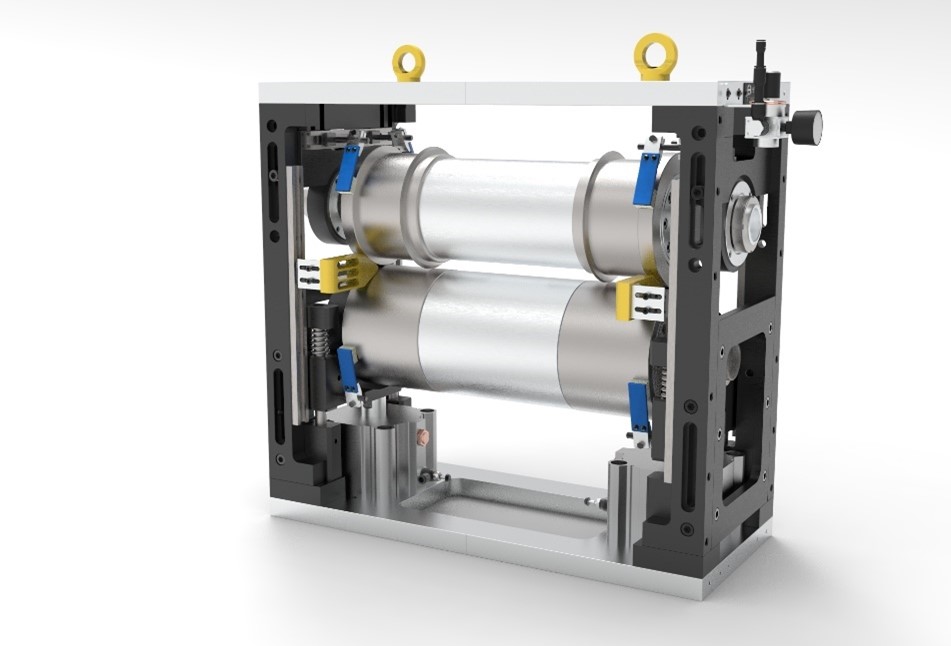

Our skills in process and automations allow us to create « specific machines », meeting your needs and issues.

OUR ECO-RESPONSIBLE ENGAGEMENTS :

MIHB is ISO 14001.

CONTACT US

E-mail : sales@mihb.com

Tél. : +33 (0)4 74 81 71 10

www.mihb.com