Hall 10 – Booth E50

#LiBS #CompositeCurrentCollector #BatterySeparatorFilm #CapacitorFilm #BOPP #BOPET

about us :

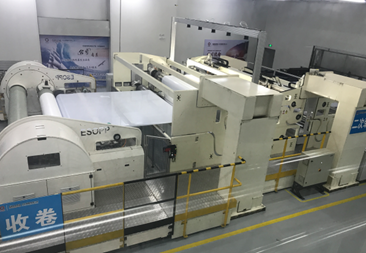

With over 30 years of experience and expertise, ESOPP designs, manufactures and installs turnkey bi-oriented plastic film production lines. Our teams are highly skilled engineers who see each project as an opportunity to push the limits of technology with new ideas. These innovative film solutions will have multiple applications from food packaging to solar energy, and from smartphone screen to batteries.

At ESOPP we ensure that every project ends up being a new piece of technology. Producing customized production lines based on their intended use and your requirements, such as the technicity and thickness of the film, productivity, process flexibility, budget, and environmental impact, inevitably leads to unique state of the art line. Innovating to meet these challenges is literally our daily life. The nature of such made-to-measure projects ensures that quality is our foremost priority. We challenge our competitors to offer the same standard of tailored solutions for your market needs.

ESOPP focuses on both sequential and simultaneous stretching lines featuring the most advanced technical designs. Our strength is to design and manufacture production lines for very high-tech film with a wide range of applications such as BOPI, BOPVF, BOPTFE, optical films, capacitor films, membranes, and battery separators film both in wet and dry process. We work with cutting-edge technologies always being renewed thanks to our integrated R&D center, pushing the development of tomorrow’s films, and taking the industry as a whole.

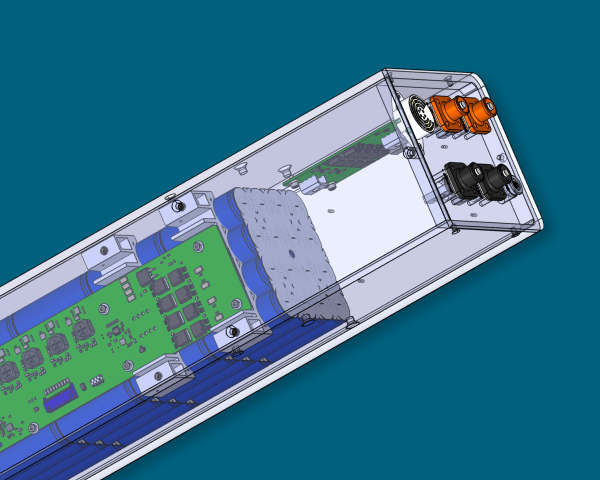

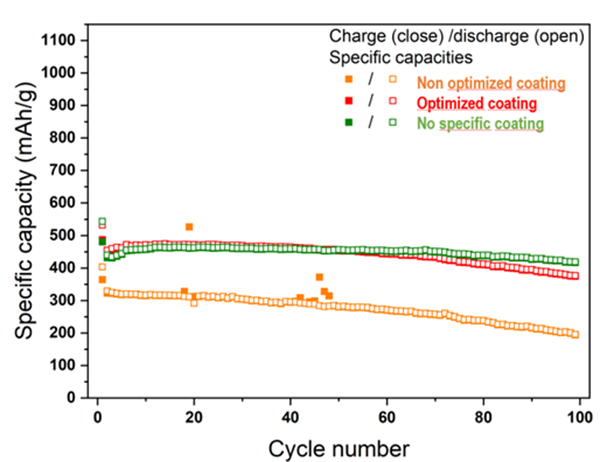

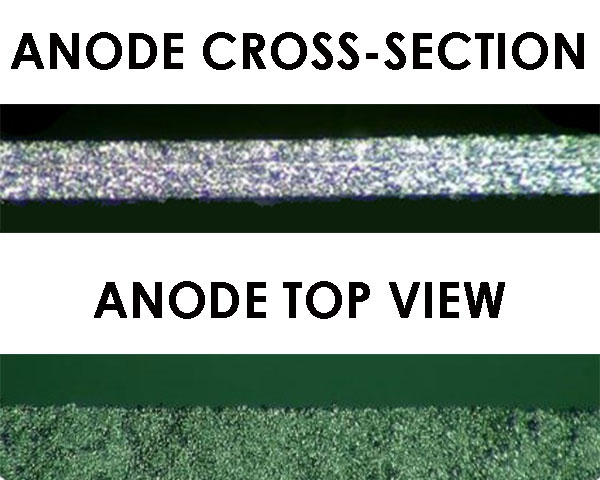

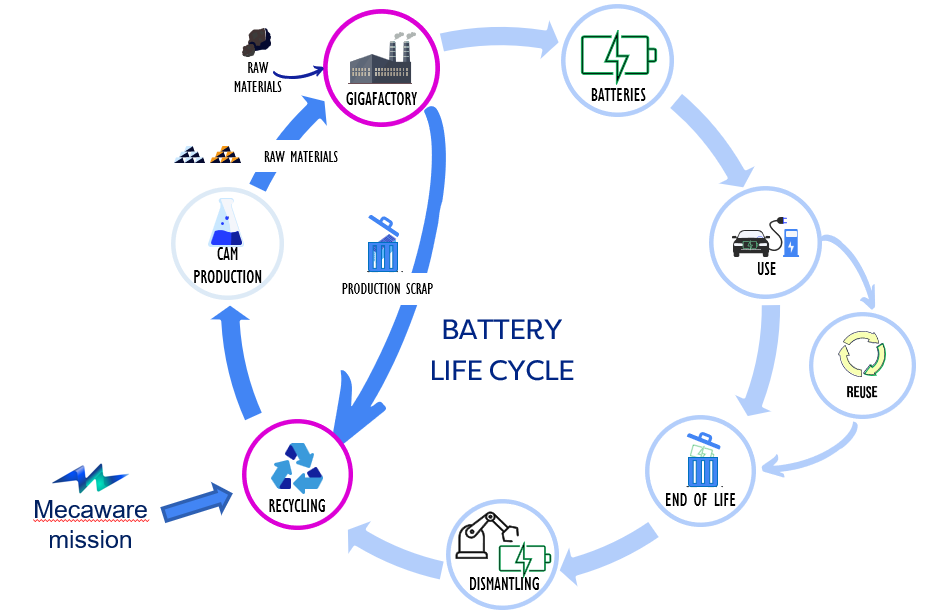

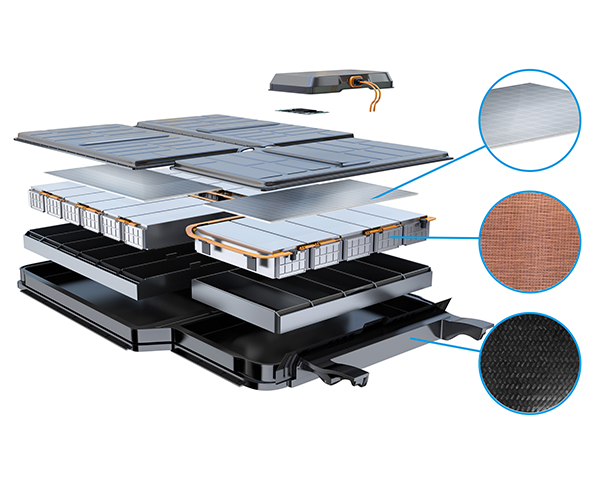

Battery separator (LiBS) production lines with a speed of 100 m/min and a width of 7 m, simultaneous or sequential stretching.

The best solution for homogeneous porosity and pore size.

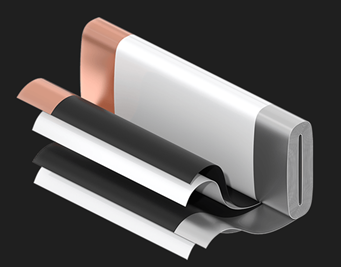

Base films production lines for composite current collectors.

Ultrathin capacitor film lines.

To produce films with a thickness from 1.8 to 5µm for capacitors and super capacitors.

OUR ECO-RESPONSIBLE ENGAGEMENTS :

We do not have yet any certification for eco-responsibility. It is part of our daily job. It is planned for our next steps.

CONTACT US

24 Rue Aristide Bergès – 73000 CHAMBERY – France

E-mail : info@esopp.fr

Tél. : +33 (0)4 79 26 51 00

esopp-group.com/