Hall 9 – 9-B30

#CompensationPads #ThermalManagement #FireProtection #CasingPads #BatteryHoldingPads #BatteryPackageSealing

about us :

Founded in 1950, Carpenter Co. is the world’s largest vertically integrated manufacturer of polyurethane foams. Carpenter also serves a diversified global marketplace with polyurethane chemical solutions, polyester fibers, thermal and insulation solutions through a network of more than 70 production locations.

Our 6,500+ employees across the globe seek to provide the most innovative products and solutions with a focus on enhancing the quality of people’s lives while being a good steward of our resources.

Among others Carpenter serves the mobility and industry sector:

MOBILITY

In Mobility, our portfolio includes solutions for conventional and electric vehicles, aircraft, aerospace and a wide range of public transport applications. Engineered to deliver tailored silencing, sealing and filtering attributes for acoustically and thermally challenging environments, including batteries and engines. Carpenter also offers foam for seating covers and accessories, headliners and door panels.

INDUSTRY

For use in industrial equipment, white goods, HVAC systems, metal processing or in packaging solutions, our engineered foams deliver tailored silencing, sealing, filtering and protecting attributes throughout the industrial sector.

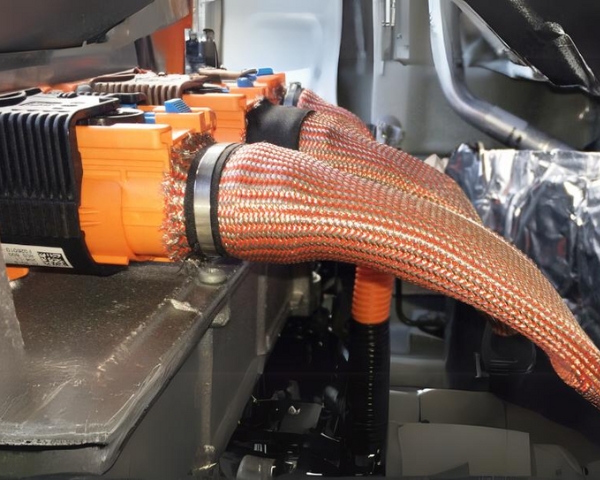

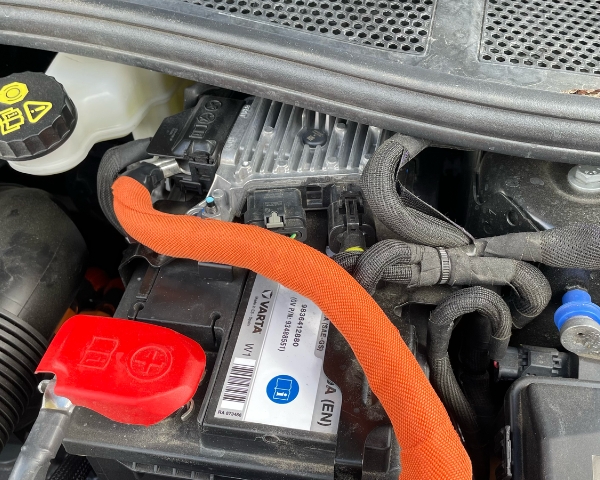

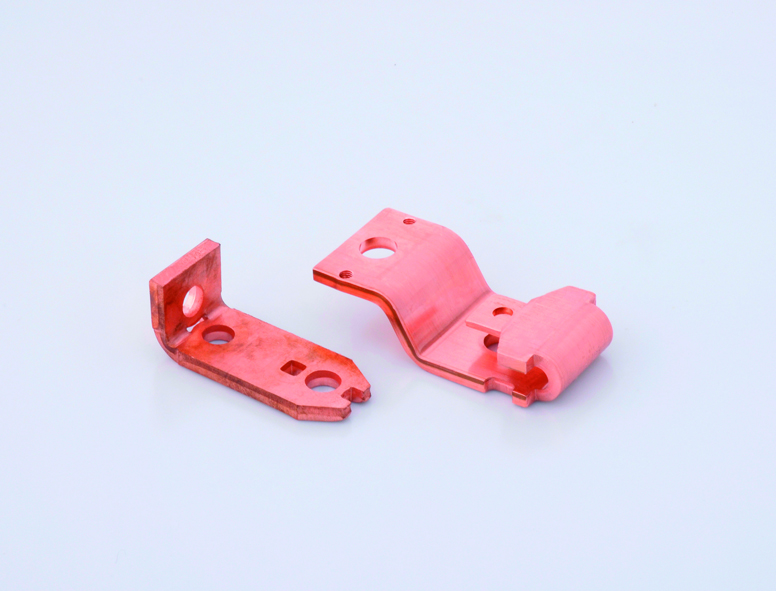

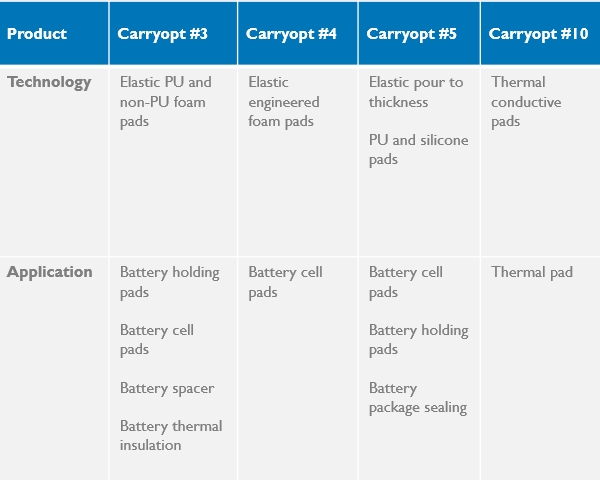

A portfolio dedicated to EV batteries & thermal control solutions for any cooling system, Carpenter provides purpose-designed pads and materials to protect, seal and thermally insulate the battery cells and battery pack.

Our Carryopt product lines are engineered for optimal carrying and support of battery components.

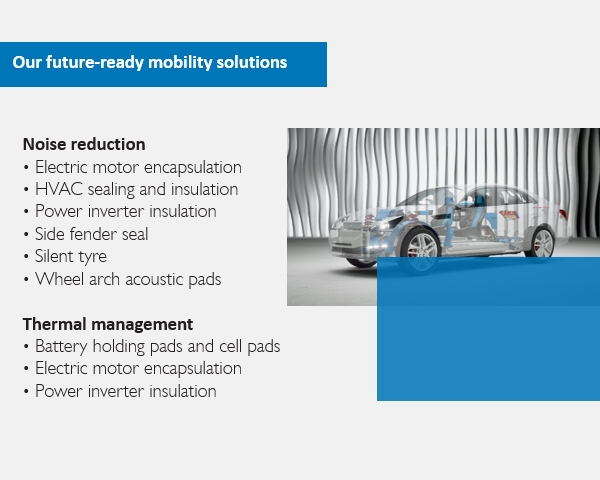

While silencing efforts have traditionally focused mainly on the powertrain, tomorrow’s solutions need to address the growing importance of road and wind noise and thermal management of the battery. Carpenter offers forward-thinking solutions for noise reduction and thermal management.

OUR ECO-RESPONSIBLE ENGAGEMENTS :

In line with the highest certification standards: ISO 9001, IATF 16949, ISO 50001, ISO 14001, Oeko-tex Step, Oeko-tex Standard 100

CONTACT US

Culliganlaan 2F, 1831 Machelen – BELGIUM

E-mail : engineeredfoams@carpenter.com

Tél. : +33 (0)9 368 92 12

www.carpenter.com