Hall 9 – 9-B20

#EOLTestBenches #LaboratoryTestbenches #HIL #RapidPrototyping #CustomDiagnosticSolution

about us :

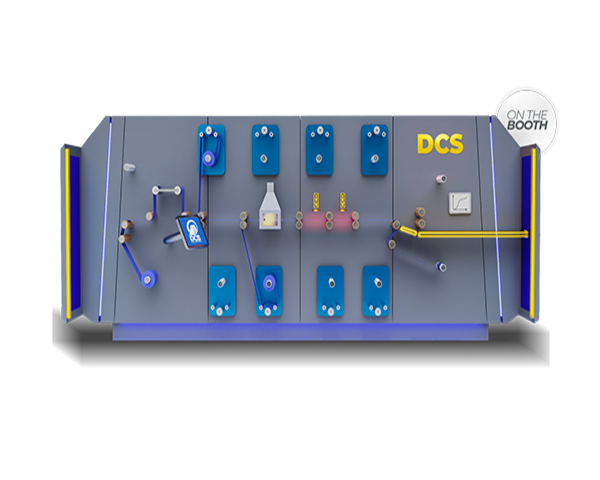

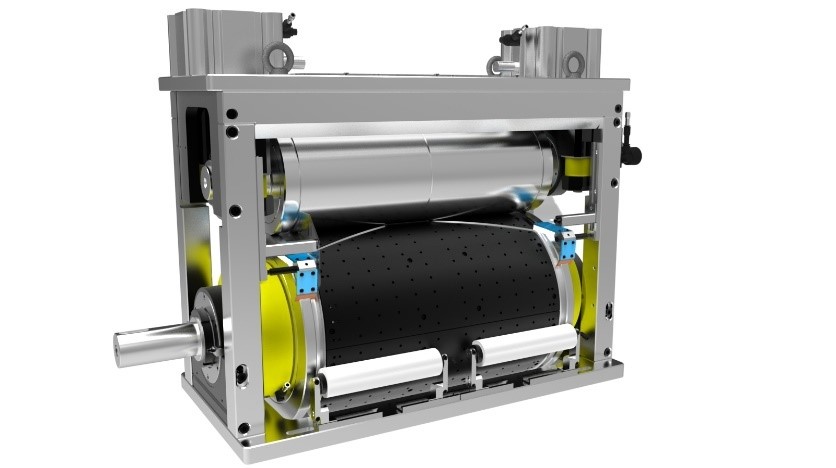

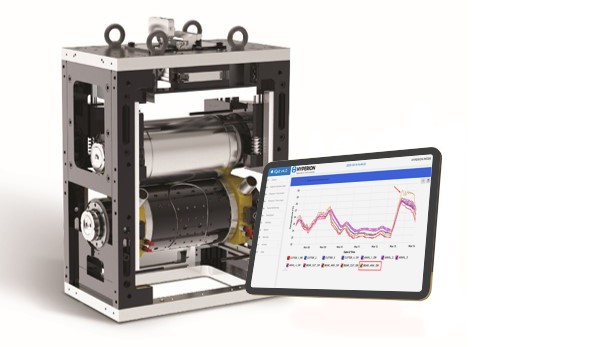

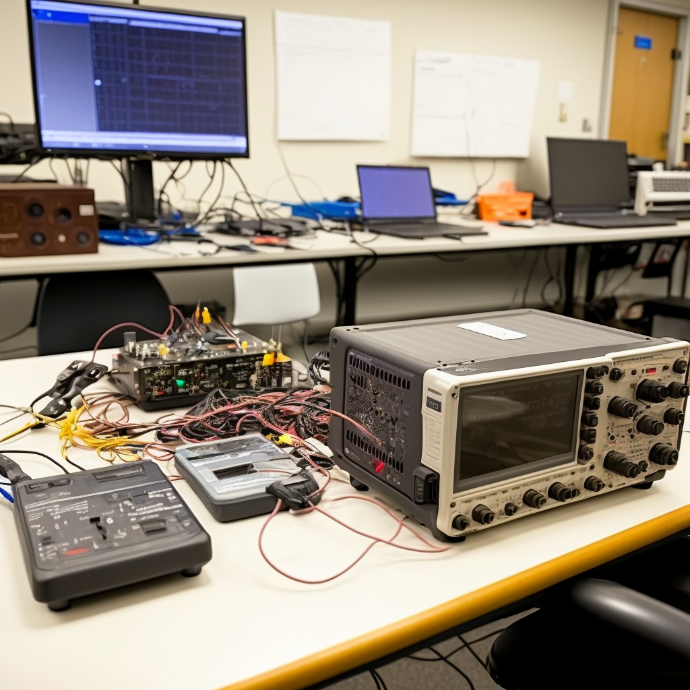

Gemesis is a company specialized in designing HIL (Hardware in the Loop) test systems, laboratory solutions, or end-of-line testing facilities. We excel in creating custom solutions with profound expertise in National Instruments’ technological platform, aiding our clients in gaining a deeper understanding of their products and enabling them to test them more quickly and efficiently. Our approach towards client collaboration is unique: we offer co-design of test means or deliver a turnkey product. However, our most distinctive feature is our open-source approach to test bench software. This policy ensures that our clients are not dependent on any single equipment manufacturer and grants them the freedom to develop their own test means on the same platform. This approach not only fosters innovation but also enhances adaptability in the ever-evolving tech landscape, ensuring our solutions remain at the forefront of testing technology. By embracing open-source, we empower our clients with the tools and knowledge to customize and expand their testing capabilities, aligning with their specific needs and challenges. This philosophy underpins our commitment to client autonomy, innovation, and the democratization of testing technology

We offer tailored solutions, including:

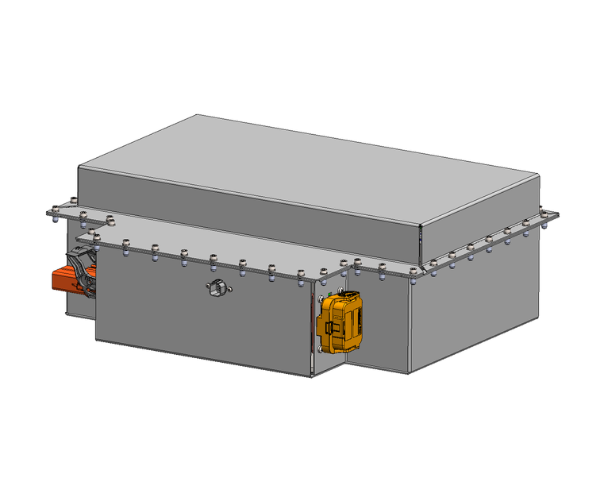

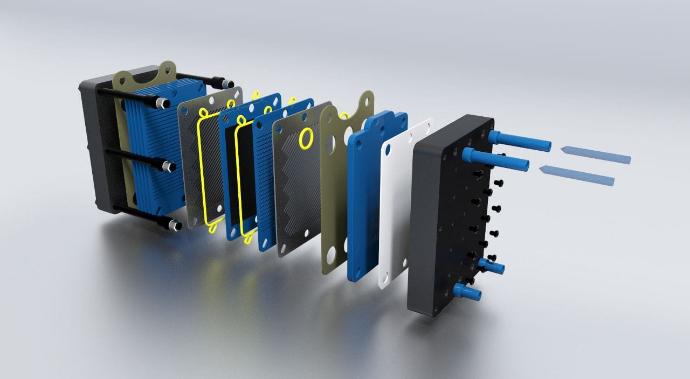

HIL for cryogenic tanks & fuel cells

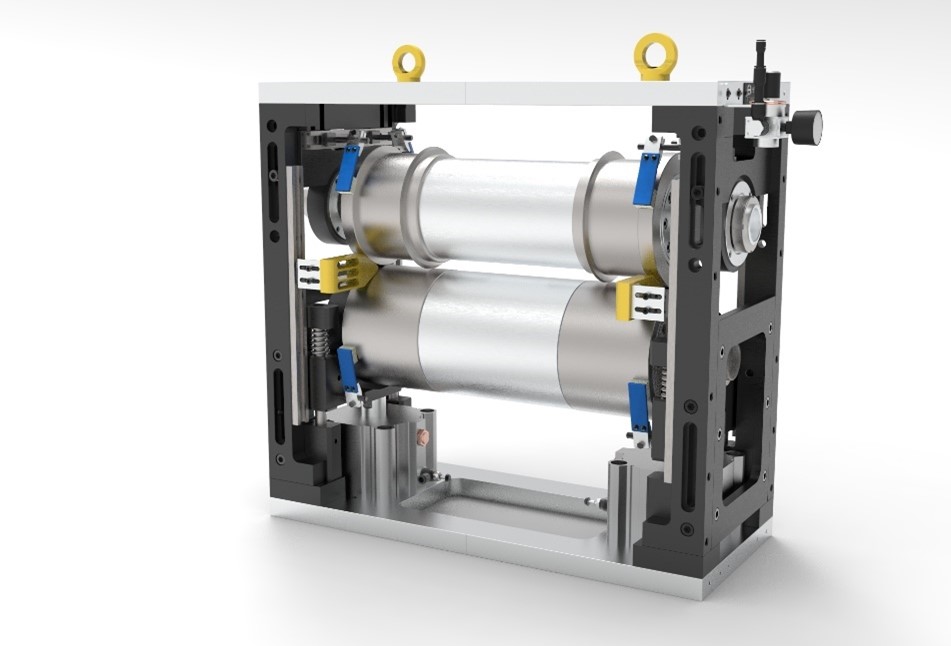

Multistack benches (up to 150 kW)

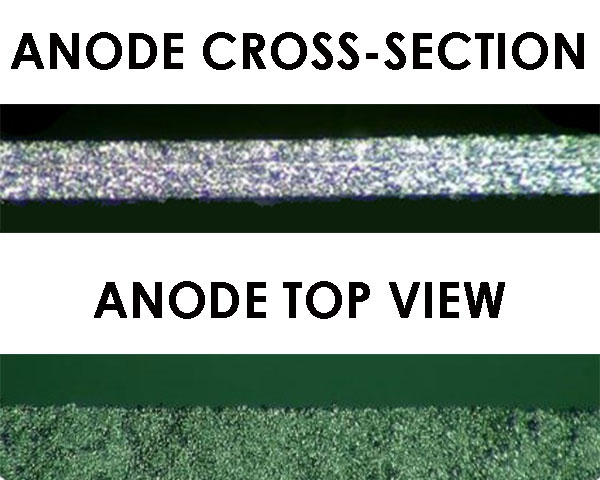

EIS on benches, MEA & plate leak tests

Stack end-of-line, high-pressure tests (1000 bars)

ECU, CVM, IrDA (J2799/J2600) benches

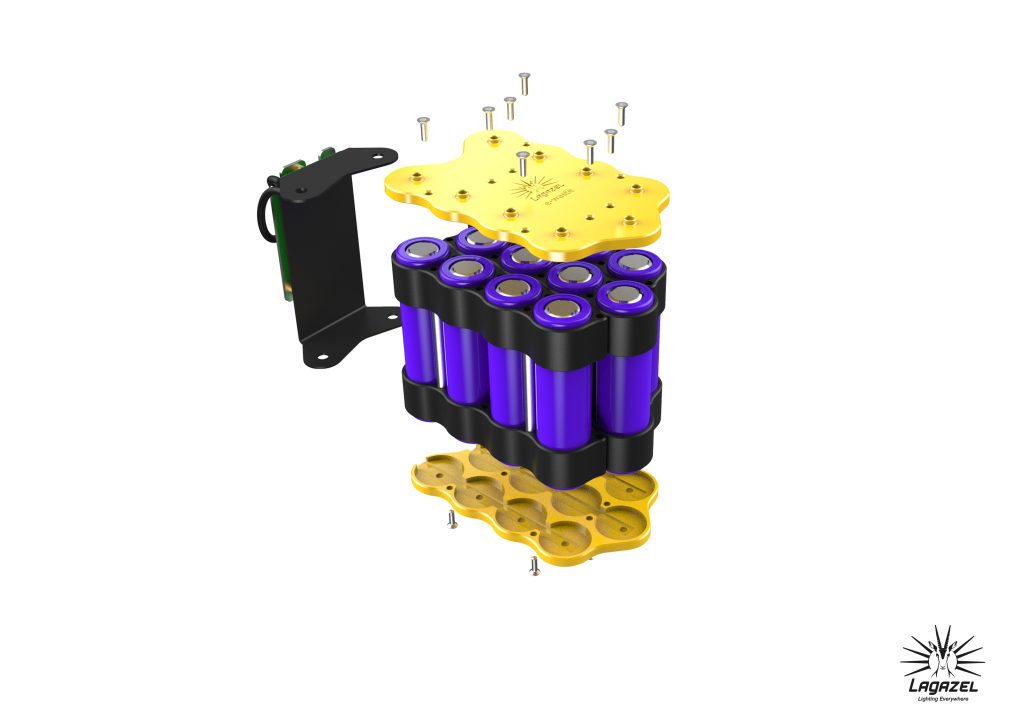

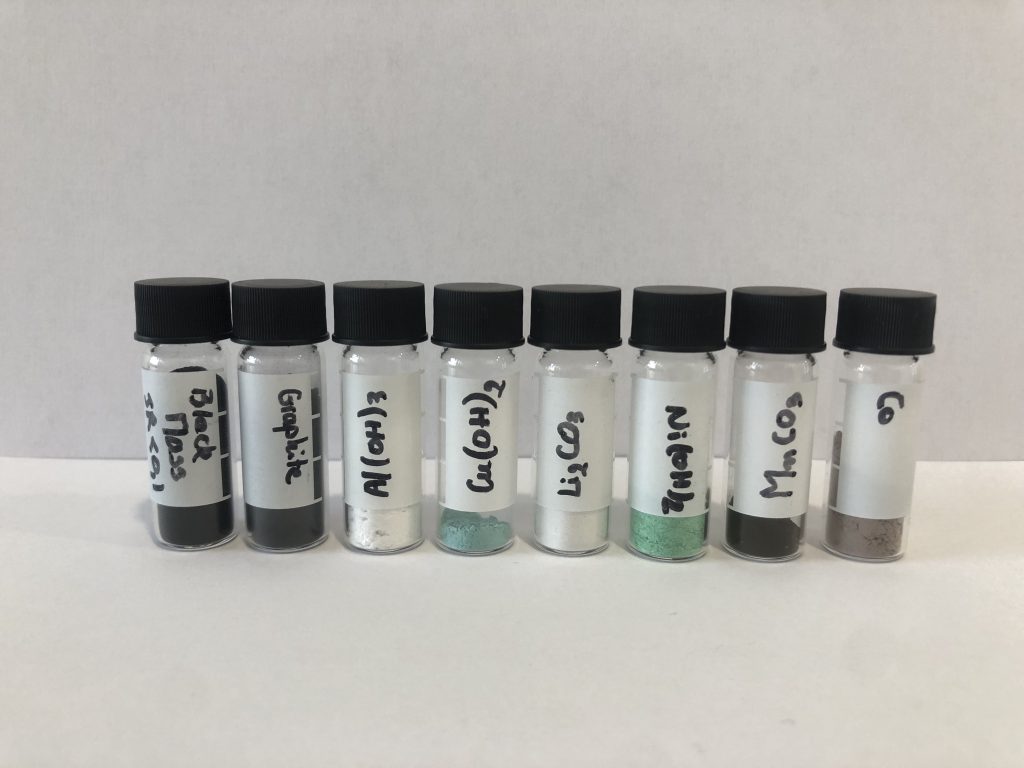

For batteries:

EOL stack tests, pressure mapping

BMS testing

We offer training on hydrogen technology and National Instruments technology. Below is a list of our training programs:

On National Instruments technology:

LabVIEW CORE 1, 2, 3

LabVIEW FPGA

LabVIEW Real-Time (RT)

LabVIEW Connectivity

FlexRIO

Web Module

G Component

DQMH (Delacor Queued Message Handler)

VeriStand

TestStand

On hydrogen technology:

Awareness on gas hazards and H2 risks

Fuel Cell Seminar

Hydrogen Challenges Seminar

Electrolyzer Week

Seminar on Hydrogen Stations and Distribution

We’ve launched a new service for testing battery and hydrogen components using drones(Skyh2 lab). This innovative approach allows for testing under controlled acceleration, reaching altitudes up to 12,000 meters with flight durations of up to 8 hours. We secure all necessary flight authorizations for these tests.

OUR ECO-RESPONSIBLE ENGAGEMENTS :

We are seeking to enhance our environmental sustainability, focusing on green initiatives. We choose energy providers that utilize solar panels and offer reimbursement for toll expenses to employees who drive electric vehicles. Additionally, we provide bicycles for shared use among our staff and prioritize train travel for employee commutes and business trips to further reduce our carbon footprint.

CONTACT US

31 rue Bellecombe – 69006 Lyon – France

E-mail : contact@gemesis.eu

Tél. : +33 (0)6 81 40 76 52

www.gemesis.eu