HALL B7 – BOOTH 530

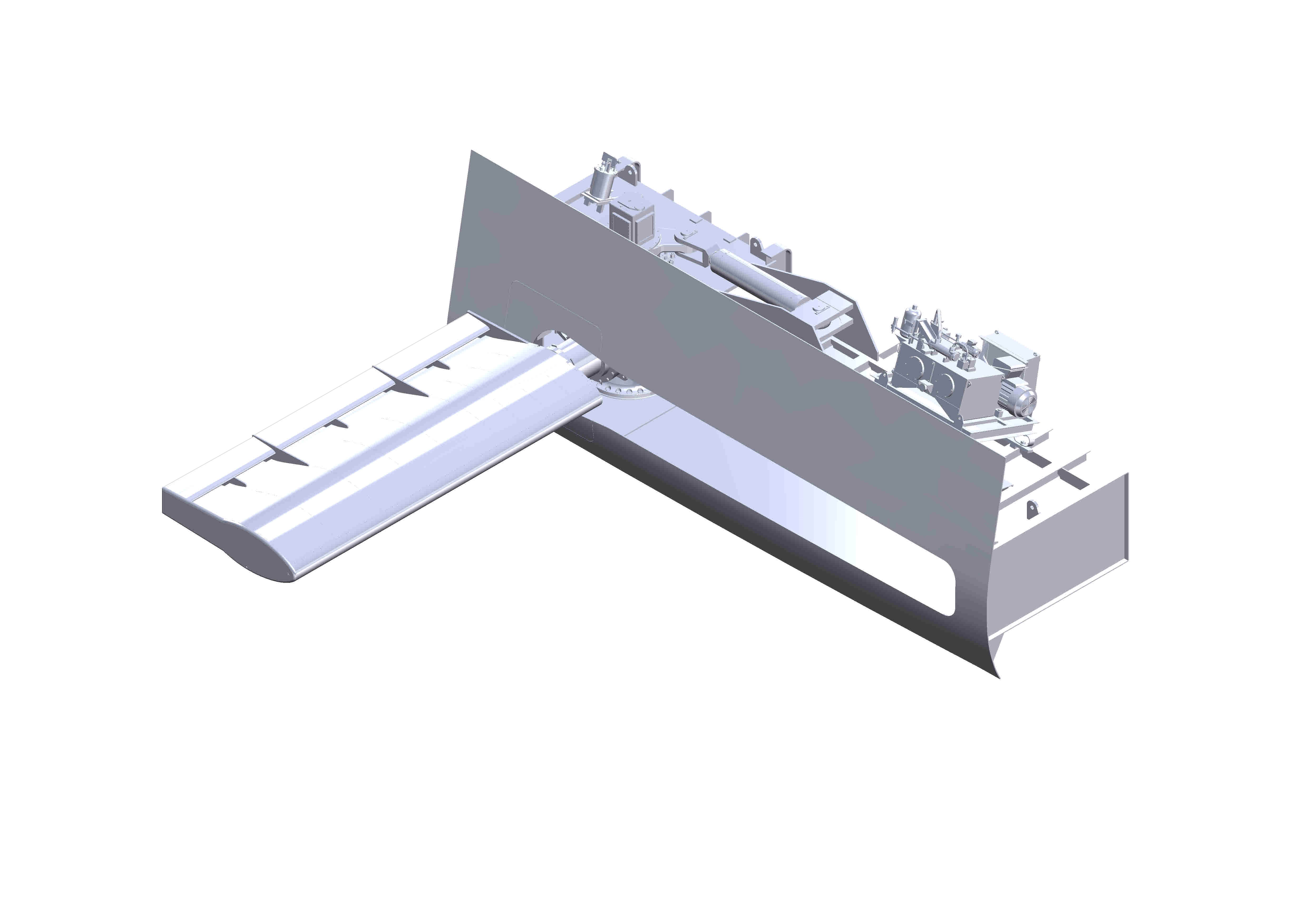

#Antidrift fins #stabilizers #Windship #WASP

about us :

Fouré Lagadec Marine is a business unit of Fouré Lagadec Group, based in le Havre, in northwest of France. Our company can rely on industrial capacities everywhere in France. Since 2018, Fouré Lagadec is part of SNEF Group, based in Marseille. For 50 years, our expertise and our know-how allow us to offer to our customer state of the art equipment, especially for stabilizing systems, anti-drift fins and cover for Bow thruster tunnel.

Development and maintenance of these systems require multiples knowledges:

– Our capacities in hydrodynamic and vessel motion allow us to develop stabilizers with recognized efficiency for passengers and naval vessels.

– Our engineers are particularly qualified to design systems subject to important mechanical forces.

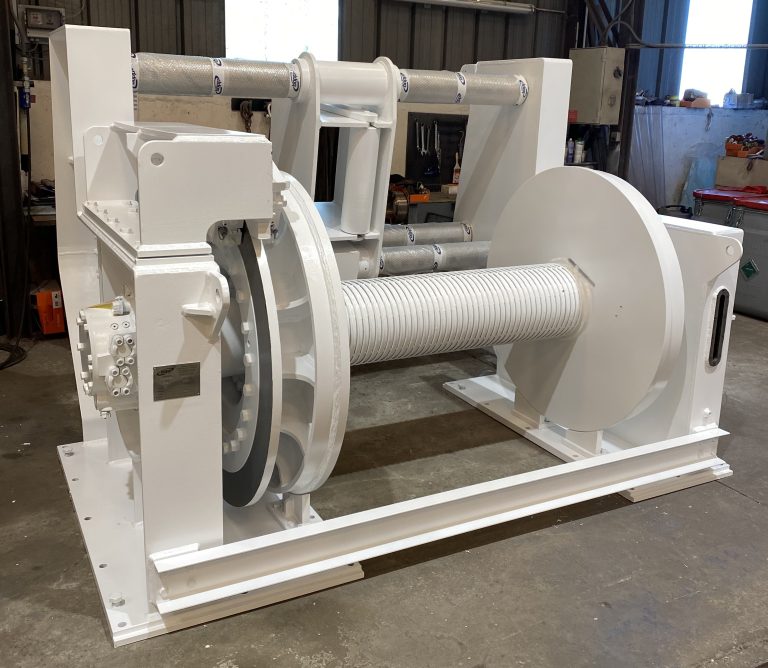

– Hydraulics and automatism subsystem are designed by our own design office and built with recognized specialists and manufacturers.

– Our technicians are able to intervene worldwide for technical assistance or scheduled maintenance.

Active stabilizers have been developed by Fouré Lagadec Marine since 1978. This equipment has been installed on several class of vessels (Cruise ships, ferries, frigates and aircraft carrier). Fouré Lagadec Marine continuously improved his systems with new features, as new fin profiles, strain sensors, predictive maintenance or cover systems.

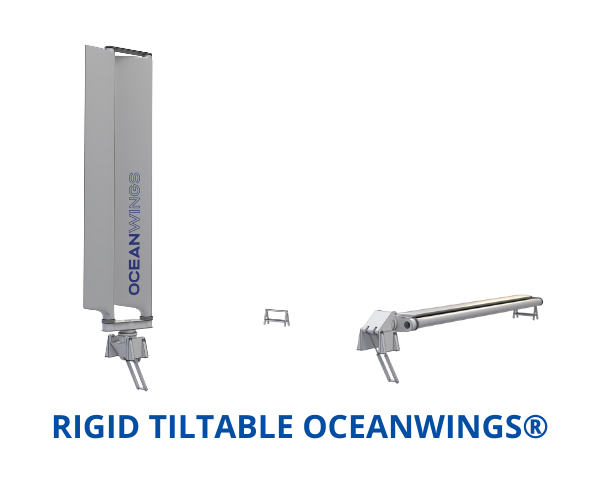

With development of sails cargo and passenger ship, a new need appears: efficient and reliable anti drift fins systems. Due to efficiency needed, active and adjustable fins are an evidence. Due to vessel size, a retractable system is also necessary. Fouré Lagadec Marine used all experience and know-how to develop a brand-new range of systems to meet market requirements.

To reduce fuel consumption, reduce drag is first and most efficient possibility. Our systems allow to close thruster tunnel when ship set sails and present a fully smooth shape in this critical area.

Our equipment took information from thrusters and is fully automated.

CONTACT US

E-mail : quentin.decroix@fourelagadec.com

Tél. : +33 2 35 25 97 76

1164 boulevard de Graville 76600, LE HAVRE – FRANCE