#Marketentry #Kick-Off #BusinessDevelopment #LocalServices #ImplementationInJapan

about us :

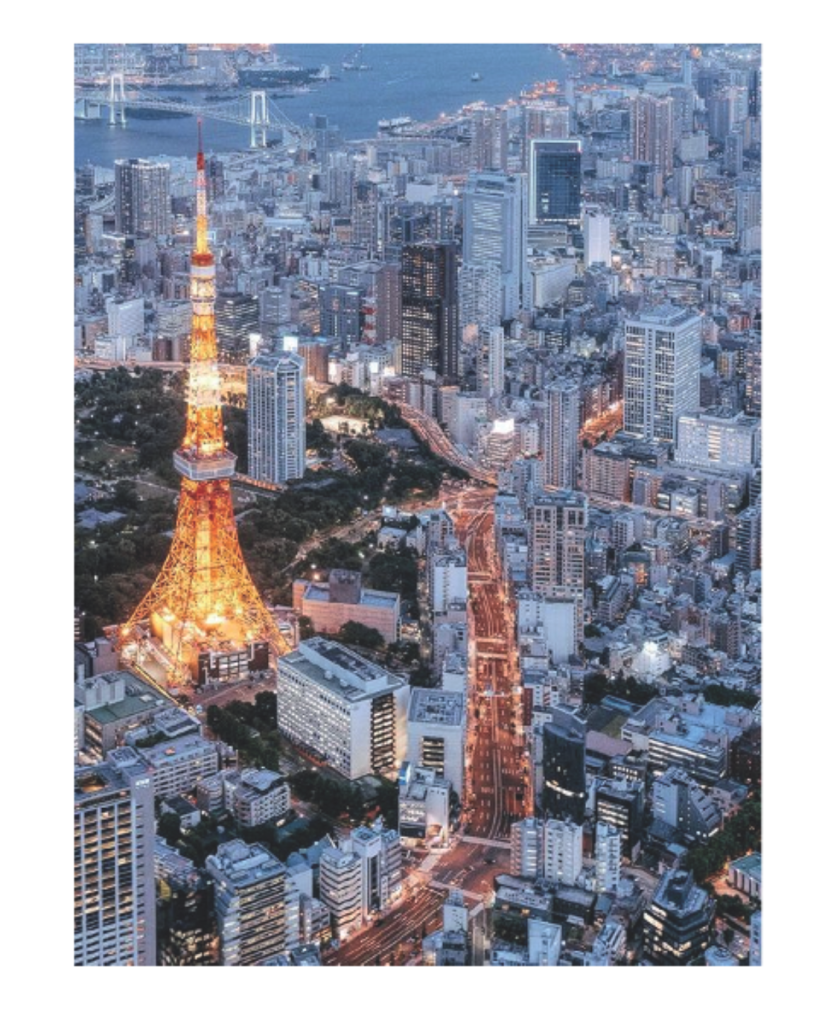

Since 1974 and located close to Tokyo Tower, PMC Japan specializes across a large range of sectors in supporting the entry and development of foreign companies’ business in Japan, serving start-ups, new entrants or companies already established with a full range of services.

As a leading trading service company, we operate in diverse sectors: brands and lifestyle, but also increasingly in manufacturing and tech, and in the medical sector, since we look for companies with a distinctive value proposition for Japan. A majority of customers are French and European.

We bring experience and provide local expertise and multilingual staff to allow you to enter efficiently into the Japanese market and operate near local clients.

CONTACT US

1-23-5 Higashi-Azabu, Minato-ku – 106-0044Tokyo – JAPAN

E-mail : fddiv@pmcjapan.com

Tél. : +81 3 62 30 98 88

PMC JAPAN