#coumpound #masterbatches #innovation #polymers

about us :

ADDIPLAST GROUP is a French family-owned company created in 1986 by Jean-Paul Chantegraille who relied on his experience as a scientific researcher in a large chemical group to develop a global high-performance offer.

ADDIPLAST GROUP has developed expertise in compound and color masterbatches formulation, manufacturing, flame retardancy, and coloring.

The main markets are : Chemicals, Automotive & Mobility, Electrical, Electronic, Appliances & Energy, Cosmetics, Healthcare, Packaging, Consumer goods and 3D Printing. The production capacity initially amounts to 20,000 tons per year.

ADDIPLAST GROUP has established itself at the international level by relying on its technical support approach from formulation to industrialization with processors.

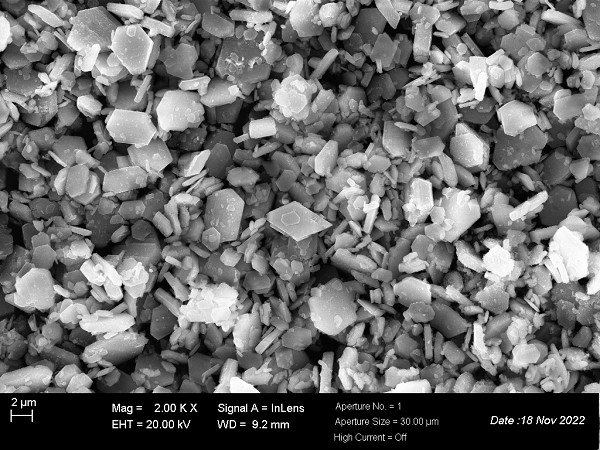

The research center, named Addiscience®, was created in 2007. Research and innovation work is carried out within this R&D center. The latter gathers engineers, formulators, technicians, doctors in chemistry, colorists, and produces more than 400 formulations per year.

At the beginning of 2013, Denis Chantegraille, then “Materials Engineer and Compounding Expert”, was appointed General Manager in order to bring a new dynamic to the group and develop technological and industrial activities in a transverse manner.

From 2014 to 2015, the Addikem manufacturing site was created. It is equipped with compounding equipment (extrusion-granulation process) by co-kneaders (2 Buss technology lines) and a co-rotative extrusion line. The activity allows the processing of high-concentration heat-sensitive polymers and fluoropolymers. The production capacity is now 10,000 tons per year. This site becomes a security and backup site for the group’s strategic customers.

In 2018, the second generation is in place, Denis Chantegraille is appointed President of ADDIPLAST GROUP.

2021 will be the year of diversification, as the group acquires a new production site located in Villers-Saint Paul in the Oise region.

This entity, named ADDICOLOR, benefits from expertise in the development and manufacture of color and functional masterbatches (PE, PP, PA, EVA, ASA, MABS, PBT, PLA, PS, PET, PET-G, ABS, PC, PMMA, SMMA). This new know-how in the fields of compounding (extrusion granulation) and in-line crystallization (PET) reinforces the development strategy of the group.

ADDIPLAST GROUP now has three production sites in France, two research and development centers, 160 employees, and a production capacity of 40,000 t.

Technical compounds formulation & fabrication

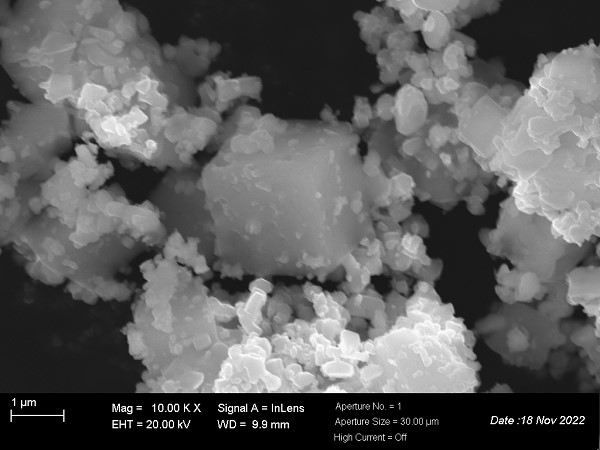

A compound consists of a thermoplastic material in the form of homogenous granules, ready to be injected or extruded, containing a polymer or a mixture of polymers, fillers (mineral, glass or carbon fibers, flame retardants, anti-wear compounds, pigments…) and additives (release agent, anti-UV, thermal stabilizer…).

The ready-to-use solutions allow to combine creativity, efficiency in production, and productivity improvement.

Functional & color masterbatches formulation and fabrication

Masterbatch is a granular concentrate of color, additives, or both.. Their high pigment and additive content allow you to use them at low dilution.

Masterbatch use offer you flexibility.

OUR SERVICES AND OUR PRODUCTION TECHNOLOGIES

Do you need to create a new product for all your future applications?

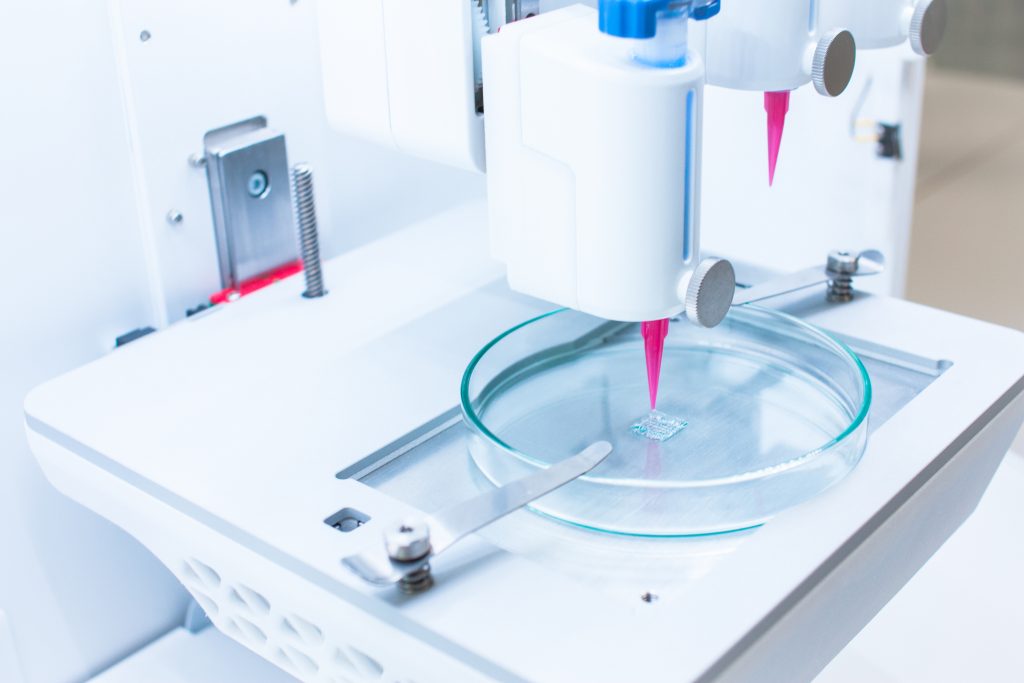

Our Addiscience® Research and Development Center offers you innovative solutions thanks to its testing and characterization equipment. Our researchers, engineers and technicians develop and invent with you the products of tomorrow.