#SDV #Manufacturing #IoT #Connectivity #Aerospace #Smartindustry

about us :

The ACTIA group is an international mid-sized company founded in 1986 whose head office is located in France. ACTIA’s business is to design, manufacture and operate electronics for the management of systems . We operate in bus, truck, construction equipment, agriculture vehicle, aeronautics, space & energy markets. ACTIA’s commitments are expressed in the group’s ambitious orientations in the service of societal issues: mobility, connectivity, security, and the environment.

We offer equipment and solutions in a wide range of fields :

– Telematics

– Connectivity & IoT

– Control domain Unit & HPC unit (SDV integrated)

– Smart HMI & cockpit solutions

– Cybersecurity & safety solutions

– Mastery of the production and design of ACTIA products is a real guarantee of quality.

ACTIA is your engineering and manufacturing partner ! Automotive quality based on technological & industrial Excellence

TELEMATICS KNOWLEDGE ACU 6

ACTIA develop state of the art connectivity platforms used by OEMs in several different market areas.

We offer a secure, flexible and powerful solution enabling endless possibilities in application development, including world wide connectivity and device management

ACU6 is aimed at customers requiring the latest in terms of secure connectivity as well as a powerful computation environment. The flexible concept means that the product can be configured for a wide range of off highway applications such as asset management and machine control. ACU6 is available in three variants to support worldwide cellular deployment and together with its flexible subscription management, forms part of ACTIA’s ‘end to end’ solution.

CYBERSECURITY

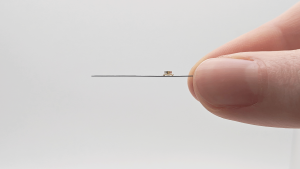

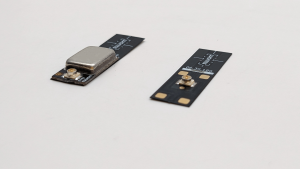

SMART ELECTRONICS MANUFACTURING SERVICES

This activity of the ACTIA group offers electronics manufacturing services in a certified industrial environment: design, production and manufacture of circuit boards at the group’s three production sites.

A comprehensive service offer dedicated to railway, aerospace, & automotive markets: Design for manufacturing, assembly, integration, Tests, logistics, sourcing , in-service support & Continuous improvement.

A foothold in the Automotive industry on an international level – An Integrated engineering – A high-performing industrial organisation

CONTACT US

Cerulean Tower 15F, 26-1 Sakuragaoka-cho, Shibuya-ku, Tokyo 150-8512 JAPAN

Tél. : 03-5456-5695 / 070-8412-9504 / 080-9805-4595

https://actia.co.jp/