Booth 5C02.J

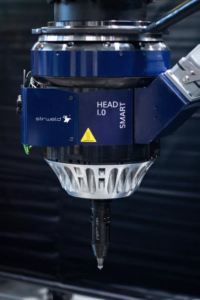

#Friction Stir Welding for CNC Machine

about us :

Stirweld team has developed a technology allowing the use of friction stir welding (FSW) on all types of CNC machine or industrial robot. We support you in the optimisation of your machine park and the integration of a new know-how to offer to your customers. Our FSW equipment’s for CNC or industrial robot offers identical performances as a special FSW machine or robot (effort control, quality recording…). Their other advantages:

– Low investment cost compared to special machines or FSW robotic stations.

– Adaptability: despite the absence of standard machining centres or robot, Stirweld FSW equipment’s can be adapted to all CNC machine types and high payload robots.

– Easy to use and to install: Only 3 days of training are needed to familiarise yourself with the FSW Stirweld equipment. We work with the automotive, space, aerospace and metal working industries.

We have a wide range of FSW equipment: FSW head for CNC machine, FSW head for CNC machine with retractable pin, FSW spindle for robot, FSW tools, FSW tool holders, prototyping.

Our FSW head can weld from existing CNC machine tools, whether it is a 3, 4 or 5-axis machine. The Stirweld FSW head brings FSW welding functions to the machining center: force control and recording, cooling, protection of the spindle against loads and vibrations. Compared to a special FSW machine, Stirweld’s solution drastically reduces the investment cost while offering identical performances.

TECHNICAL SPECIFICATIONS

– Solution designed by FSW experts

– Force control to secure the weld quality from 1 to 18 kN

– Radius force ability up to 5 kN

– Rotational speed up to 3500 RPM

– Recording of the forging force for quality control

– Quick tool change (whistle notch attachment)

FSW spindle for robot

Our robotic FSW solution allows you to weld with any high payload robot. It brings the functions of FSW to a standard robot. Your robot becomes a hybrid tool combining welding & machining with an automatic tool changer. This hybrid welding and machining spindle for robot opens up a wide range of applications: 3D welding, welding of large parts.

TECHNICAL SPECIFICATIONS

– Rotational speed up to 10 000 RPM for high welding/milling speed

– Automatic tool changer

– Maximum payload of 18 kN

– Full water cooling

– Full monitoring for 100% online quality control (according to EN 9100 standard)

– Full electrical and pneumatic power (no hydraulic power)

CONTACT US

E-mail : laurent.dubourg@stirweld.com

Tél. : +33 (0)6 47 49 74 19

1 rue Jean Thévenot – 35760 Saint-Gréfoire – France

Website : Stirweld