Booth 5D16

#MadeInFrance #Welding #Cutting #PressureReducer #Expansion #Gaz #Flam

about us :

LE LORRAIN is a French family business established in France since 1946.

Our company applies its technical expertise and technology to manufacturing a complete range of gas welding equipment.

All our welding, heating and cutting torches, regulators, quick connectors and accessories are manufactured and tested according to European and international technical standards.

A personalised service offer and dedicated experts!

Driven by an ambitious team and growth strategy, LE LORRAIN is banking on a new dynamic whose main focus is innovation.

Making the most of its expertise and know-how to help its clients meet the challenges they face is of prime importance to LE LORRAIN.

LE LORRAIN is committed to providing its distributors and users with the best level of service: from the design of a customised product to after-sales service, including the qualification of an installation and training to ensure the best use and guarantee the safety of users.

In addition to being a French manufacturer, LE LORRAIN aims to be a partner that works daily to contribute to the creation of added value for its own customers’ professional activities via personalised services and offers:

A RESEARCH AND DEVELOPMENT DEPARTMENT

Listening, understanding and innovating to meet the specific requirements and needs of customers. The Research & Development department assists LE LORRAIN customers, from the drafting of specifications to the design of a tailor-made product.

TECHNICAL ASSISTANCE

Analyse a specific situation, qualify an installation, advise on the choice or maintenance of equipment by telephone or in person. Need help? contact contact@lelorrain.fr or + 33 (0)3 83 35 47 98

TECHNICAL ASSISTANCE SPECIFIC TO GAS NETWORKS

Support, advice, guidance, correction or drafting of specifications specific to the construction or maintenance of a gas network.

PREVENTIVE VISIT

Carry out a complete diagnosis of the company and be guided in the preventive maintenance of all the installations. The on-site visit is carried out by a LE LORRAIN expert technician who provides a detailed report with the best practices to adopt and ensures a follow-up of the transfer of technical skills on the use of the equipment.

CALIBRATION BENCHES

Control the performance and safety of your installations.

From on-site calibration to laboratory calibration in our factory, we offer calibration services adapted to all your needs to guarantee the conformity of your regulators.

AFTER SALES SERVICE

Carrying out diagnostics, preventive maintenance and/or repairs within a defined timeframe according to user constraints.

LE LORRAIN ACADEMY

To pass on, train and support its customers in their development. LE LORRAIN ACADEMY, a certified training organisation, is committed to providing each learner with a training programme adapted to their development objectives.

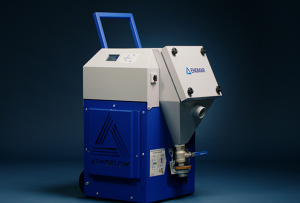

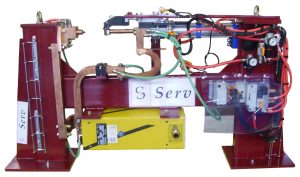

NEW DEI ECONOMIZING REGULATOR – Reference 054600.

A double-stage regulator with an economiser device allows better priming of welds and better management of gas consumption.

47% gas savings compared to a standard regulator!

– Prevents damage to the solenoid valves of your welding unit

– Prevents “water hammer”.

– The amount of gas trapped in the pipes is divided by 4.

– Optimum gas savings for spot welding.

High pressure cutting torches HP1 – reference 200400.

The two major advantages of this product range are robustness and simplicity of operation and maintenance.

All HP1 high pressure cutting torches operate on the principle of mixing oxygen and fuel gas in the head. This type of mixing ensures that the user minimises flame ingress.

The design of the HP1 torches is optimised with a round handle, the opening of the cutting oxygen by a lever (trigger) located below the handle.

Torch inlet threads vary according to country of use, supplied on request.

Cutting heads from 7 to 40/10 for cutting from 3 to 360 mm.

Flash back arrestor

In the event of a flashback, the flame can travel at the speed of sound and manual intervention becomes impossible and the risk can go as far as the explosion of gas cylinders.

Our standard flameproof flash back arrestor LE LORRAIN devices reduce these risks.

They comply with the EN730-1 and ISO5175-1 standards and ensure optimum safety.

Consisting of a safety valve and a filter, if a flashback occurs, the filter immediately contains the flame; as it passes through the fine porous structure of the filter, the flame loses its energy and is gradually smothered. At the same time, the safety valve closes automatically.

CONTACT US

E-mail : victor.dasilva@lelorrain.fr

Tél. : +33 (0)3 83 35 47 98 – +33 (0)6 75 37 91 45

12-14 rue Marcel Brot – 54000 Nancy – France

Website : Le Lorrain