Booth 5C02.F

#HardfacingWelding #TungstenCarbideCoatings #Nickel-based Powders #Oxy-acetyleneWelding #TungstenCarbideFlexibleRopes #WearResistantSurfacing

CONTACT us :

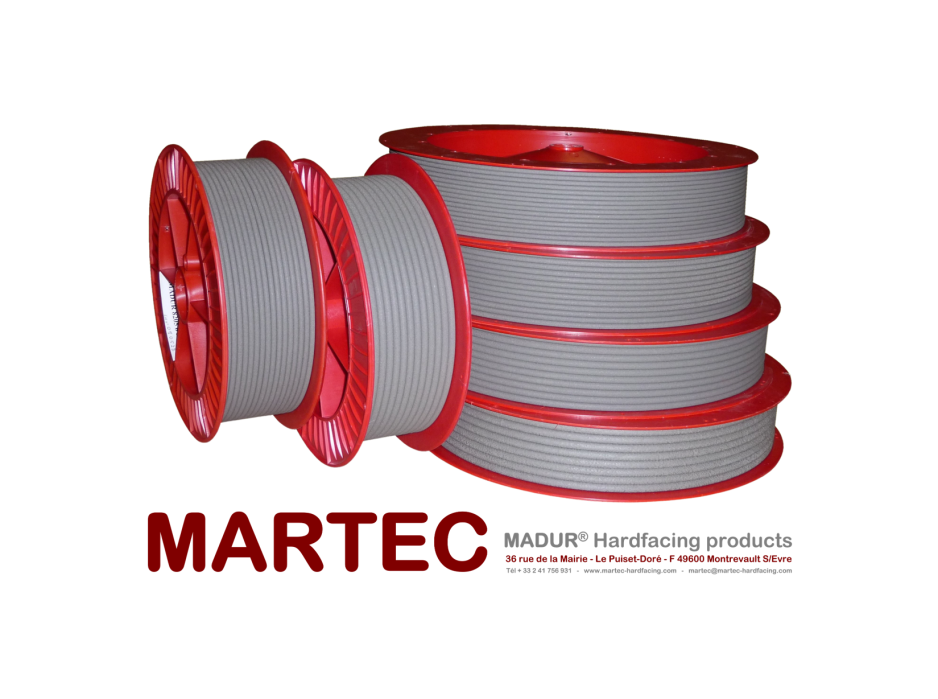

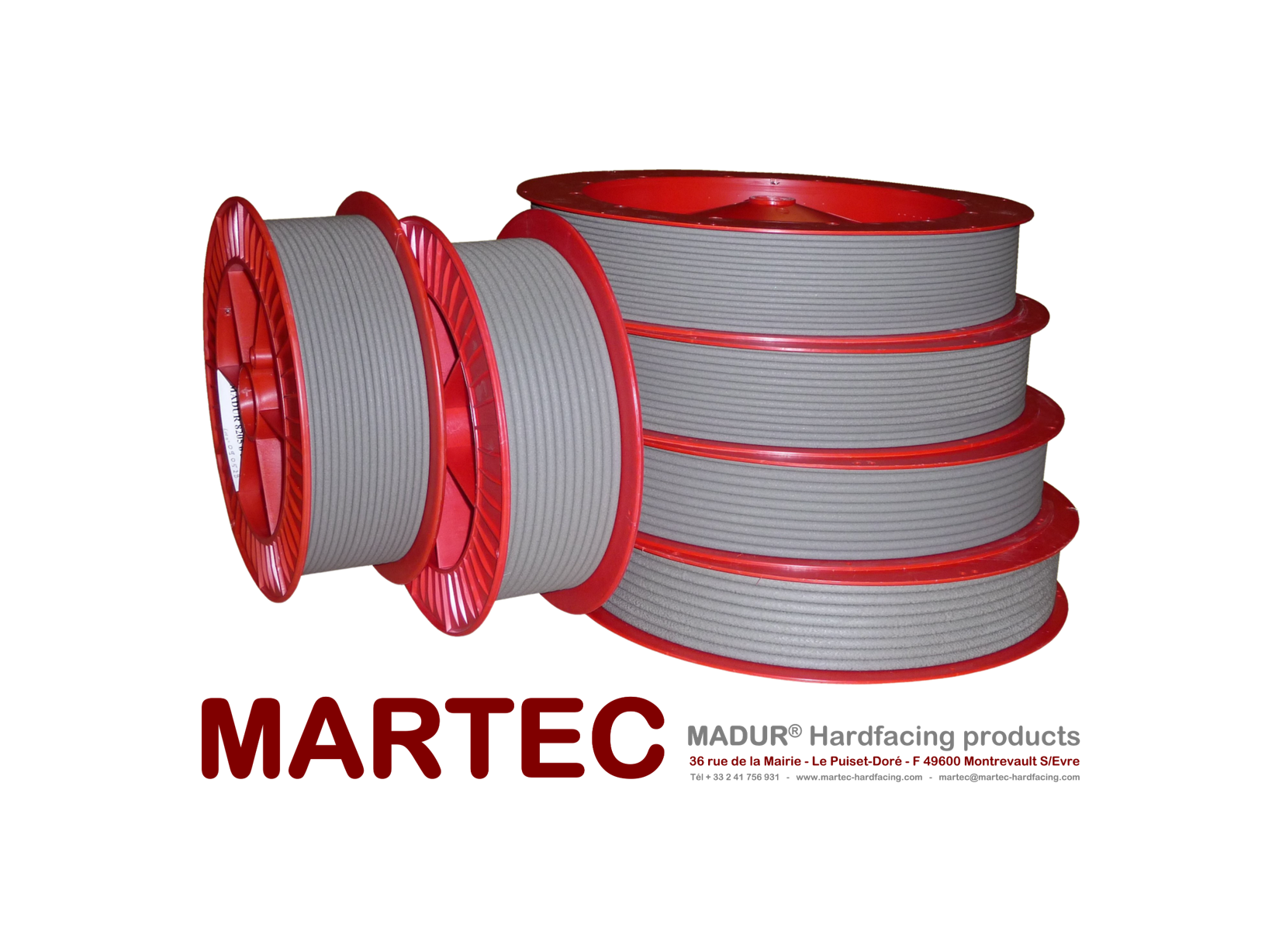

Near the city of Nantes, MARTEC, a French company, has been developing a range of MADUR® hardfacing materials for over 30 years. Our kow-how and experience have helped us to provide our customers with competitive solutions to meet industrial wear requirements. Our core business is the development, the manufacture and the sale of hardfacing tungsten carbide flexible cords. We can offer hardfacing Nickel-based powders and the suitable welding equipment to use our products. The oxy-acetylene MADUR® cords and powders are exported worldwide to all industry areas with abrasion problems. MARTEC is the reliable partner in hardfacing wear protection solutions.

MARTEC is the exclusive producer of the MADUR® Hardfacing Tungsten Carbide Flexible Cords : a high quality coiled electrode composed of a Nickel core wire with thick coating, consisting of an Nickel-chromium-boron-silicon alloy matrix and a high content of crushed or spherical tungsten carbides. When surfacing, the Nickel-based powder matrix and the core wire fuse with tungsten carbide particles like a brazing, thus forming a tough coating, and bonding with the base material. The protection against abrasive, erosive and corrosive attacks is increased. MADUR® wires are developed for oxy-acetylene welding and exported worldwide to various areas, e.g. ceramic, oil & gas, mining, cement and steel industries.

MADUR® Hardfacing Powders :

MARTEC offers 2 types of Metal Welding Powders :

-Nickel-based Powders – hardness from 20 to 60 HRC

-Nickel-based Powders – hardness 60 HRC with 20 to 60% crushed or spherical tungsten fused carbide

Welding Powders are designed to give a smooth, dense coating and are particularly suitable to repair cast iron parts and protect small parts like molds in the glass industry. MADUR® hardfacing powders are normally applied by an oxy-acetylene flame spraying process.

Welding the MADUR® cords and powders involves a suitable oxy-acetylene torch. MARTEC supply the designed and simple to use equipment.

CONTACT US

E-mail : bmary@martec-hardfacing.com

Tél. : +33 (0)2 41 75 69 31 – +33 (0)6 07 90 85 95

36 rue de la mairie, Le Puiset Dore – 49600 Montrevault-sur-Evre – France

Website : Martec