about us :

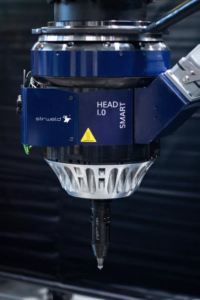

Metal-Interface is an online medium dedicated to the sheet metal industry. It offers manufacturers technical content in the form of articles, videos and technical dossiers on specific topics.

The Metal-Interface site also offers companies the opportunity to post job vacancies, classified ads and company listings.

Metal-Interface also offers innovative and highly targeted marketing solutions. To this end, Metal-Interface has a powerful database of companies working with sheet metal, with precise details specific to the sheet metal industry, such as machinery, key contacts, etc.

All Metal-Interface services are available in 5 languages: English, German, Italian, Spanish and French. Our journalists work in these 5 languages.

CONTACT US

E-mail : benoit.cantin@metal-interface.com

Tél. : +33 (0)1 84 16 61 03 – +33 (0)6 07 25 10 54

75 avenue Parmentier – 75011 Paris – France

Website : Metal-Interface