Booth 5C02.E

#Electrode-holder #Earth-clamp #Welding #Protection

about us :

Soudo-Métal is specialized in welding and protection glasses with a clientele made up of welding specialists and companies of industrial supplies.

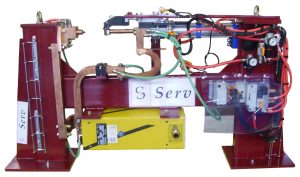

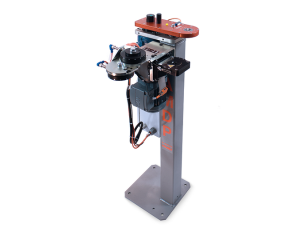

Located at the time in Morez (Jura), the society had proceeded in 2003 to the buyout of the range of electrode-holders Métalarc of the company Thermodole, and this way has taken over the exclusive production and marketing of the products Stubby®, Master® and Tongrip®.

Thanks to this acquisition, which reinforced its range of products Arc 500®, Vestalette®, Fusion®, Vestale® and Cobra®, Soudo-Métal became the n°1 in France in the very specific market of electrode-holders and welding accessories.

Soudo-Métal has known how to build its reputation on the quality and the performance of its production. Thanks to Soudo-Métal, you have the guarantee of a manufacturer mastering its activity, from design to manufacture. Our items are produced and packaged with an extreme precision.

We are a French manufacturer of Electrode Holders : STUBBY, MASTER, VESTALE, COBR, TONG GRIP…

We are able to supply welding glasses and plastic screens for all dimensions.

CONTACT US

E-mail : cyril.lahaye@soudo-metal.fr

Tél. : +33 (0)3 84 66 39 10 – +33 (0)7 56 88 86 80

382 chemin du Mont Rivel – 39300 Champagnole – France

Website : Soudo Metal