Booth 5C02.P

#Welding #ElectronBeamWelding #SpecialMachine #Solution #HighTech #High-endSectors

about us :

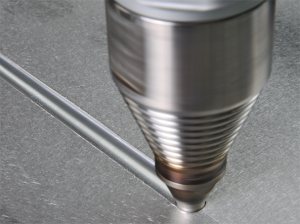

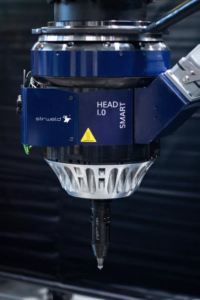

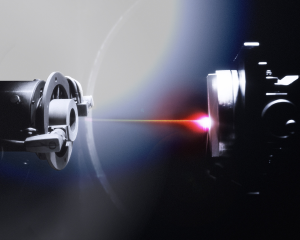

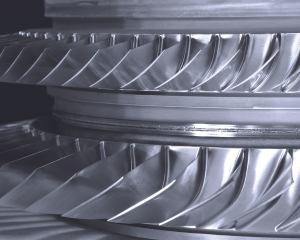

Major electron beam technology supplier in the world, TECHMETA offers solutions that cover all areas of EB welding and develops a set of solutions through its unique expertise in the production of complex welding and in the design and manufacture of special welding machines for over 60 years.

TECHMETA is the only machine manufacturer that has owned and mastered indirect heating technology. Since always, TECHMETA has accompanied its customers in all their projects, even the wildest, always leading to success.

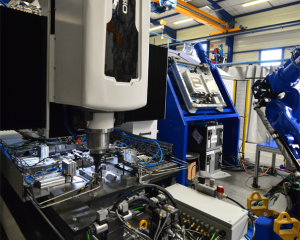

Thanks to their flexibility and their responsiveness, our teams and our partners are able to help you all along the product’s life cycle, by developing the welding process and the welding machine, then ensuring technology transfer and training of your team.

Techmeta is active in high-end sectors such as aerospace, defense, research, nuclear industry, automotive industry and medical technology active.

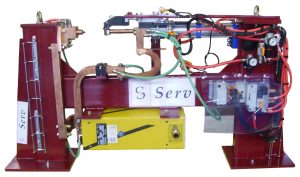

Buying a new machine can be expensive; TECHMETA repairs, retrofits and upgrades old machines. Improve production rates and entrust us with the modernisation and upgrading of your installations.

On demand, our experts can evaluate your requirements and recondition your machine on your premises.

Do you want to make the most out of your machine’s performance? Our team can provide customised training either online or on site! Production programming, knowledge of tools to secure the parts to be welded, maintenance of machine components such as vacuum pumps, advanced understanding of control and calibration of electron beams, etc.

CONTACT US

E-mail : jyjulia@techmeta.com

Tél. : +33 (0)4 50 27 20 90

141 Route des Machurettes – 74370 Epagny Metz-Tessy – France

Website : Techmeta