about us :

The Weez-U Welding solution combines an ergonomic controller, a vision system dedicated to welding, and a collaborative arm.

Intuitive to use, the solution operates with modern robotics technologies. The welder is kept at distance from danger and can express his art. He controls in real time a complex welding operation.

The robot can be automated for repeatable parts and offers the flexibility, quality and performance expected by the companies of the sector.

The WeezBot solution is composed of a joystick, a real-time control core, a vision system, and a collaborative arm. The handling is extremely intuitive and uses modern robotic technologies in an original way.

Its large amplitude enables non-stop welding, guaranteeing optimal quality and no leaks. All angles are accessible. It is the only one on the market that allows the welder to control a complex welding operation.

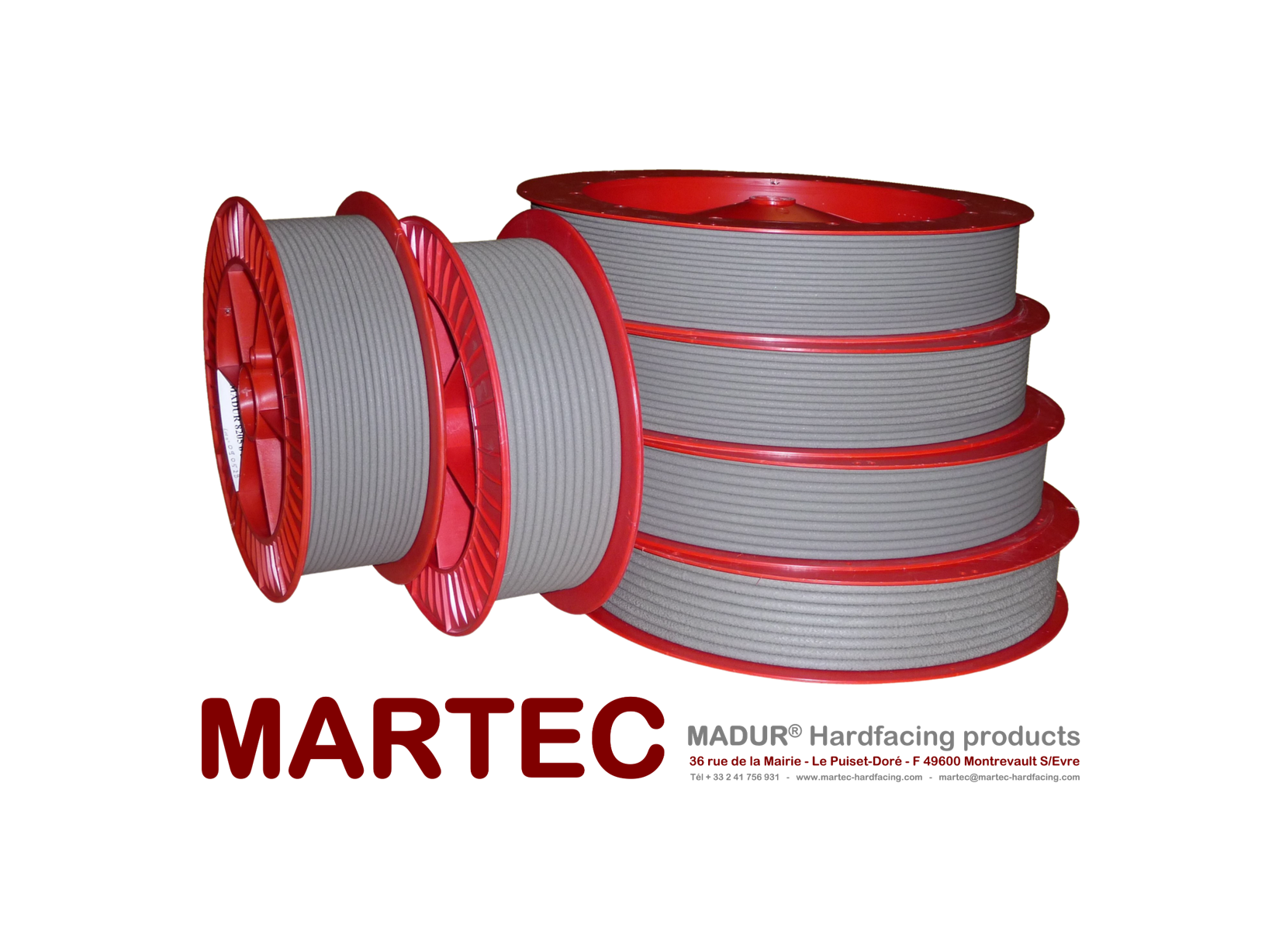

Easy and quick to use, the solution allows the use of a wide range of welding materials.

The ergonomic WeezTouch controller is designed with and for welders. It is intuitive to use. It allows precise, real-time control of the welding process, reducing any welding errors or need for finishing.

It puts distance between the welder and the weld which improves his working conditions. The welder practices his art, concentrates on his tasks, corrects in real time, to the second and to the millimeter.

The welder’s performance and the company’s productivity increase, while saving time and energy.

Our high definition camera helps the welder to see his weld and to correct it in real time. His controlof the gesture is total and meticulous, errors are avoided thanks to an optimized trajectory as the weld is made.

The videos of our vision system can also be recorded to facilitate the training of your welders, as well as the understanding of their errors in order to avoid repeating them.