Booth 5C17

#Welding #Welder #Extraction #Torch #MIG #TIG

about us :

ENGMAR is specialized in the extraction and treatment of welding fumes since 1993. We manufacture high vacuum solutions while optimizing workstations for optimal ergonomics.

Thanks to our integrated design office, ENGMAR produces turnkey systems, adapted to all types of workstations (manual, robotized or automatic…). Here, we propose MIG/MAG and TIG welding torches for manual, automatic and cobotic welding, systems to extract and filter nuisances, as well as solutions to improve the ergonomics of workstations.

Welding fume extraction systems are adapted to production needs, environmental constraints and comply with current legislation. This is why ENGMAR extraction solutions guarantee efficient protection of operators, as well as high performance.

ENGMAR also offers associated services such as the installation and maintenance of the solutions, but also the training of the user employees concerning the risks of welding fumes and the use of our equipment.

Extraction torches

ENGMAR offers MIG/MAG and TIG extraction torches to capture the welding fumes as close as possible to the source of emission. Our competence in both welding and extraction ensures quality welding seams even in hard-to-reach places, in welding with flux-cored wire, aluminium or in spot welding. Our ambition here is not only to extract some, but most of the welding fumes and to protect the welder in the best possible way. For this purpose, we offer a complete range of air- and water-cooled MIG/MAG torches from 150 to 500 amperes with 45°, 50° and 60° lances as well as T9, T20 and T17 TIG welding torches.

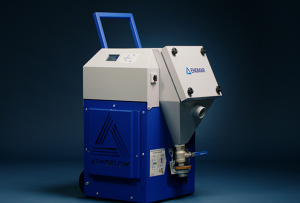

Extraction unit ATMOFLOW

ENGMAR innovates and introduces a new extraction unit to its customers: the ATMOFLOW. Designed for the filtration of welding fumes, it promises performance and mobility. Combined with a high vacuum equipment (MIG/MAG or TIG extraction torch, laminar sensor, floor vacuum cleaner…), the ENGMAR ATMOFLOW extraction unit allows to treat the pollutants from welding fumes in a powerful and efficient way. It has 2 levels of filtration allowing to filter 99,999% of the particles of 0,3 μm and more. The ATMOFLOW has a user display showing messages, alerts and audible signals to guide operators in the daily use and maintenance of the unit.

Central extraction unit

ENGMAR’s high vacuum suction units allow the simultaneous operation of several suction equipments (MIG/MAG and TIG extraction torches, laminar nozzles…), in order to treat the pollutants coming from welding. ENGMAR’s extraction units are designed according to the customer’s needs. We make a precise adjustment of the electrical consumption according to the number of stations in operation, which allows to reduce the energy and operating costs according to the real production in the workshop. The cleaning of the extraction units is done automatically. In addition, they offer the advantage of a single maintenance point and a limited space requirement.

CONTACT US

E-mail : juliane.osmont@engmar.fr

Tél. : +33 (0)2 28 08 28 29 – +33 (0)7 84 28 68 47

ZA La Poste, Impasse du Pré Rond – 69490 Saint-Romain-de-Popey – France

Website : Engmar