Booth 11P-B153

#ThermoformedTray #TechnicalHFweldedpouch #Injectedindustrialpiece #Medicaldeviceblister #Industrialpackaging #Thermoformedmachinecoverm

about us :

Family group of 7 companies, Velfor is specialized in packaging solutions.

Each unit is dedicated either on a technology or on a market.

We produce thermoformed blisters, trays, covers, as well as industrial pieces. Most of our productions are customized.

We have a unit dedicated to high frequency welding, specialized in technical bags (pouches).

We are also able to produce injected pieces.

Our strength, beside an interesting range of technical possibilities, lies in our ability to co design customized solutions based on customers specification. Thanks to 50 years expertise, we are well known for that.

Our sustainable development innovation service (design and material) brings added value to your projects: ergonomics, practicality in use, eco-designed solution, optimization as well as new material proposal.

We are proactive as well as supportive on regulatory issues.

ISO 9001 and 13485 certified, we are able to answer most of your demands, up to contract packing.

Our Innovation Department is working on looking for new base material and qualifying the optimum ones.

Committed in the circular economy for years, the group is organized in a virtuous way in terms of waste reduction. Each company of the group has the MORE label since 2019.

We care about you as much as we care about our future.

Feel free to contact us, we will be delighted to study your next project.

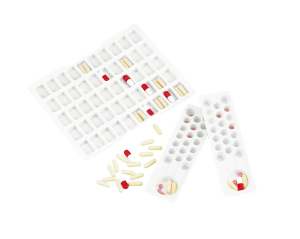

Thermoformed customized pill boxes.

We will be delighted to design the perfect model for you, both in terms of external as well as inner dimensions. Various base material and sizes, as well as base material thicknesses available.

Feel free to contact us, we will come back to you very shortly.

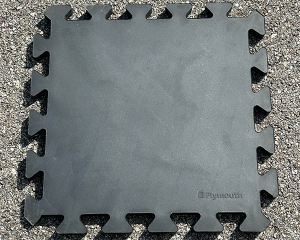

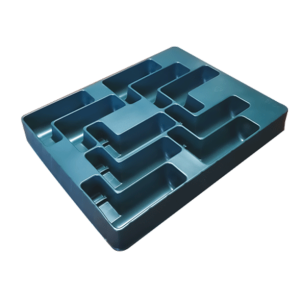

Thermoformed handling trays. One way or reusable.

From thin to thick base material. ESD possible.

Our offer will answer your specification for the best.

CONTACT US

E-mail : contact@velfor.com

Tél. : +33 (0)4 71 61 30 51 – +33 (0)6 75 68 37 80

www.velfor.com