Booth 11P-B153

#Groissiat #Tranformtosuccess #MIHB #Sustainable #RSE #PlasticValley

about us :

Expertise, business offer:

MIHB, a specialist in the transformation of thermoplastic materials, is a recognized expert in the design and industrialization of technical parts with high added value, from appearance parts to fluid management and motion transmission systems.

MIHB supports you from the choice of plastic materials to product design, tooling development and robotic expertise. A transversal approach that also revolves around our Design Office, our DTP department, and our know-how in rheology, metrology, assembly and logistics.

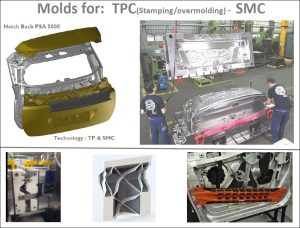

MIHB masters the following technologies: mono, 2k, 3k, 4k injection, over-molding, extrusion, IMF, IMA

Metrology: MIHB is equipped to perform all types of products measurements (3D scanning, QV 3D videos, roughometer…)

Customer references, significative projects: parts for hydrogen sector, production and automated assembly of 27 components for gearbox motor in home automation sector, cleanliness fuel parts ISO 16232, cars’ keys for automotive sector and covers for the paramedical sector.

Target markets, industry addressed:

Future Mobility: Batteries / Hydrogen / Autonomous Cars / Automotive / Other Mobility outside Automotive Sector

Current Mobility: Diesel / Synthetic Gasoline

Divers: Home Automation / Buildings / Paramedical / Agricultural / Leisure

CONTACT US

Parc Industriel de Nerciat, 215 Voie Romanie, 01100 Groissiat

E-mail : contact@mihb.com

Tél. : +33 (0)4 74 81 71 10 – +33 6 82 62 91 97

https://www.mihb.com