Booth 11P-B147

#Rubberrecycling #Rubbermixing #Rubbercalendering #Rubbersecondlife #Elasticrubbertapes

about us :

Plymouth Française is a European leader in the processing of rubber into thin sheets (production of elastics for underwear, swimwear, diapers, FFP2 masks, etc.), and has developed an innovative solution for recycling rubber production waste using a unique thermomechanical devulcanization process. This process does not require the addition of any chemicals, which sets it apart from other rubber recycling processes, and enables the recycled rubber to be reintegrated into a new compound (thus saving on raw materials, eliminating incineration costs, etc.). Scrap rubber can thus be recycled ad infinitum. An environmentally virtuous process.

This regenerated rubber is reincorporated into a new mix at a percentage varying between 5% and 75%, depending on the quality of the final product. It can then be recycled ad infinitum.

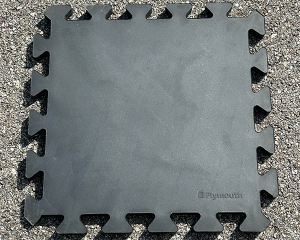

Recycled slabs made from used rubber from ski resorts: a second life for a French product!

Rubber sheets and elastics rubber tapes used for closing manufacturing, industrial application or hygiene and medical products. Those products contains recycled rubber.

CONTACT US

21 allée du Rhône – BP1, 69551 Feyzin Cedex

E-mail : contact@plymouth.fr

Tél. : +33 (0)4 72 09 29 29 – +33 (0)6 07 53 73 78

www.plymouth.fr