Booth 11P-B153

#RecyclingEquipment #SmartFactory #RecyclingInnovation #PersonalizedSolution #Physico-ChemicalRecycling

about us :

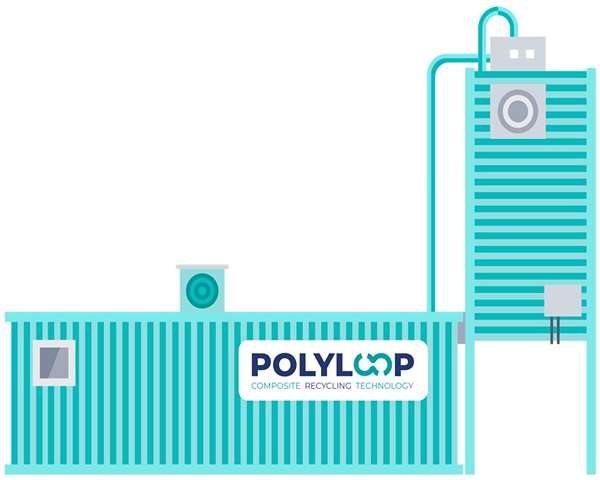

Polyloop is developing a compact and easy-to-use recycling solution dedicated to complex plastic waste such as PVC composite materials.

Polyloop provide a simple solution to a complex problem: the recycling of composite plastics by optimizing an effective and proven process, encapsulated in a turnkey recycling unit and can be integrated as close as possible to the waste sources.

Polyloop provides this missing key to plastics manufacturers and manufacturers concerned about the future of their materials, who in turn wish to work for a more circular world.

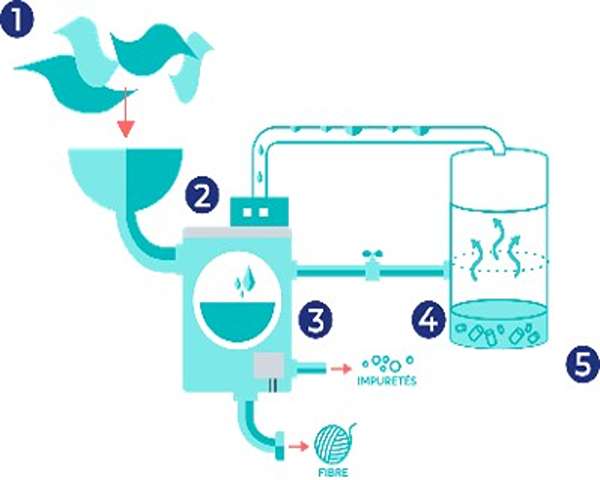

STRAP physico-chemical recycling

This physico-chemical process (STRAP) enables to separate different layers of a flexible composite product made of thermoplastics and others component. Polyloop will extract the main polymer among a mix such as fiber reinforcements, aluminum sheets, wood, another polymer…It works with PVC, PC, PVDC, PVDF, PVB…

-High material value: No depolymerization, all additives are retained

-No destruction / alteration of your materials

-Purity of recycled materials

-Increased compatibility with multiple compositions

Smart Factory

The Polyloop recycling lies in in its Smart Factory approach: compact recycling equipment for recycling “at home”. Polyloop decentralizes recycling by offering integrated modular equipment easy to use for those involved in the plastics industry.

An easy-to-operate unit :

-300 kg / batch in 3 hours

-Working 24/24

-500 tons / year

-Only 1 person to operate

CONTACT US

136 route de Triors – 26750 – Génissieux

E-mail : contact@polyloop.fr

Tél. : 07 63 64 20 29

https://polyloop.fr/