Booth 11P-B153

#Silicone #Composite #Technicalparts #Complexmolds

about us :

Since 50 years, Tier 1 specialized in molds for plastic parts injection, composites & die casting tools. Integrator of plastic solutions. Approved French R&D center. ISO 9001 version 2015 certification. Automated company at the forefront of digitalization developing 4 main activities: R&D / Innovation, Tools & Molds, Service, Machining. Technologies: Multitube (cancellation of post molding welding operations), E-Assist (connected glasses for remote and real-time diagnosis), E-Tooling (smart and connected tool), Metamorphose (automated and electric version change management), Silicone, Composite. Markets: automotive, aeronautics, building, packaging, medical etc. Machining centers.

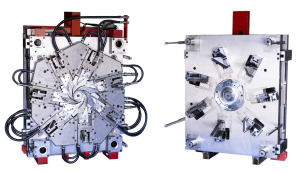

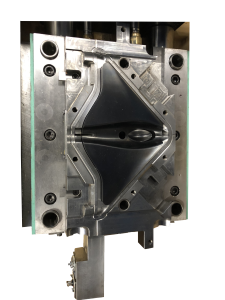

Looking for top-quality injection molding solutions for your high-tech silicone parts? Pernoud’s cutting-edge software & CNC machining ensure precise and consistent results with strictest tolerances and specifications. We are dedicated to engineering molds that deliver excellent performance, with a focus on complex geometries and tight tolerances.

Technical molds play a key role in fulfilling customer needs by enabling the production of intricate parts with complex kinematics. We design & manufacture tools for plastic part injection, composite, die casting. They ensure high-quality standards and efficient manufacturing, resulting in customer satisfaction, meeting their specific requirements.

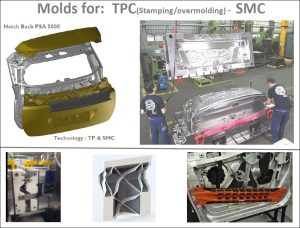

Have you issues with thermo-stamping part finishing? Pernoud has the solution, thanks to an innovative design of a mold and a gripper allowing to manufacture Netshape thermo-stamping part in 1 cycle. Moreover, this design allows to reduce cycle time and production chain by optimizing gripping operations and insuring an improved repeatability and quality.

CONTACT US

Parc Industriel La Prairie – CS 90099 – 01100 Groissiat

E-mail : info@pernoud.com

Tél. : +33 4 74 77 50 84 – +33 6 63 71 81 63

www.pernoud.com