Booth S25157H

#BatterySeparatorFilm #Film #ProductionLines #Capacitor #MIC #Biax

about us :

MARCHANTE is a family-owned company, specializing in designing extrusion lines for biaxially oriented plastic films. Founded in 2010, by Innocent Marchante, with 30 years of industry experience (Cellier, DMT), the company conducts a significant portion of its business through exports, customizing film production lines for Asia, Latin America, and Europe, covering technical films (including Battery Separator films, Capacitor films), packaging (BOPP, BOPA, Monomaterial BOPE, BOPET), and more. As the company achieved remarkable growth and profitability, in 2021, MARCHANTE opened its Innovation Center (MIC) composed of a cast extrusion line and a dynamic stretching simulator, with the support of BPI France and the AURA Region in France, dedicated to researching film applications, especially in recyclable packaging. In a pivotal move to better serve its clientele, especially in the Asian market, MARCHANTE is set to open a subsidiary in China. This strategic step aims to strengthen proximity to customers in the dynamic Asian context.

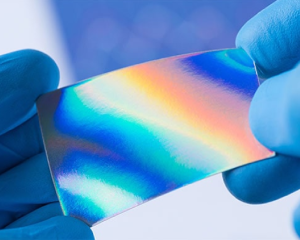

As extrusion and biaxial stretching experts,our primary focus lies in crafting technical films such as BOPP Capacitor, High °C Films, and Li-BSF (wet and dry). We also offer expertise in a wide range of plastic film applications, BOPET, BOPA, PETG, BOPS, Stone Paper, Shrink-Sleeve materials, R&D including mono-material & bio films such as BOPE, Bio Polymers, and 100% rPET for thermoforming.

A battery separator is a critical component in electrochemical energy storage systems, acting as a barrier between the positive and negative electrodes to prevent electrical short circuits while allowing the flow of ions for efficient energy transfer. MARCHANTE puts its technology at the service of separator producers to improve quality, productivity of their line and safety of the separator. Our simultaneous stretching system, MASIM, is a prime example, alongside MDO (Machine Direction Orienter) and TDO (Transverse Direction Orienter) systems.

Established in 2021, the Marchante Innovation Centre (MIC) is a unique film development center based in France – an hour away from Geneva and Lyon. By housing the MIC in MARCHANTE SAS, with our StretchLAB (orientation simulator) and CastLAB (multilayer pilot co-extrusion line), our primary goal is to provide practical solutions to meet the dynamic demands of the market.

CONTACT US

E-mail : caroline.marchante@marchante.fr

Tél. : +33 (0)4 56 29 53 17 – +33 (0)7 56 18 18 44

29 Av. Paul Louis Merlin, 73800 Montmélian, France

Website : https://www.marchante.fr/