DISCOVER THEIR SOLUTIONS

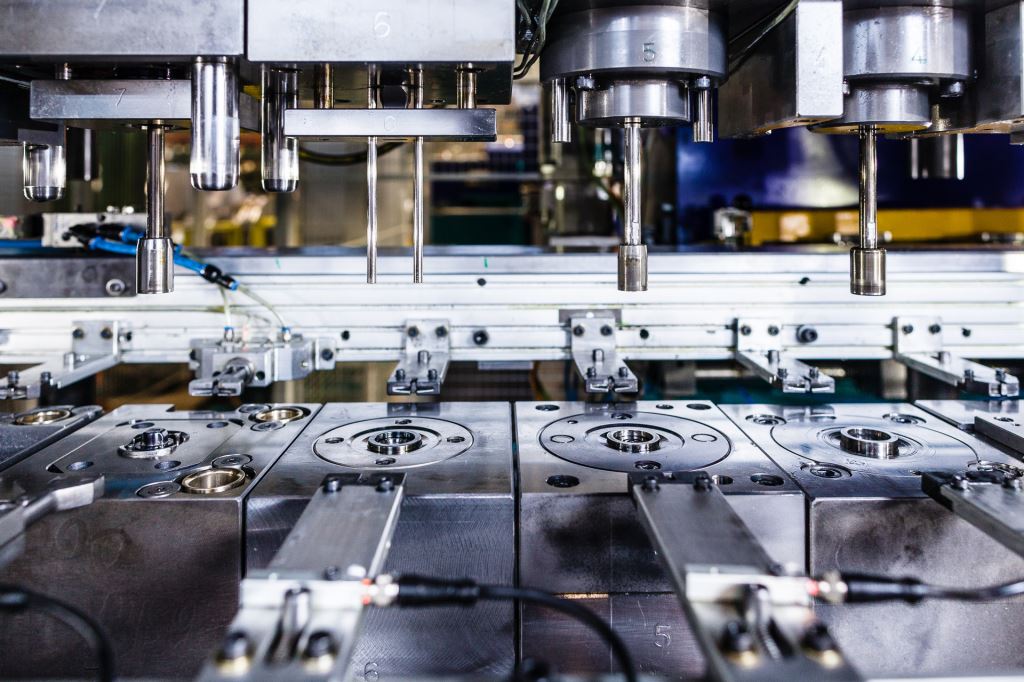

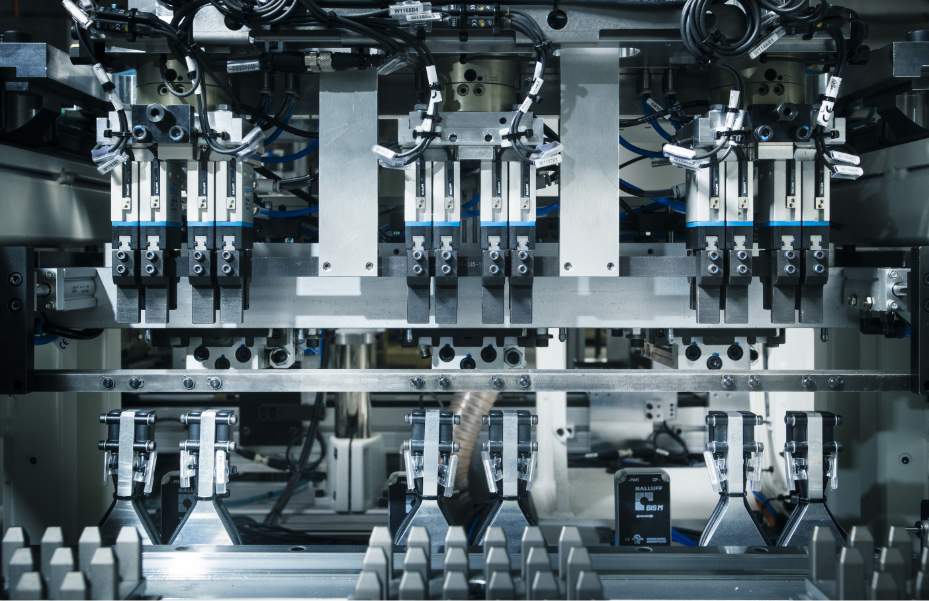

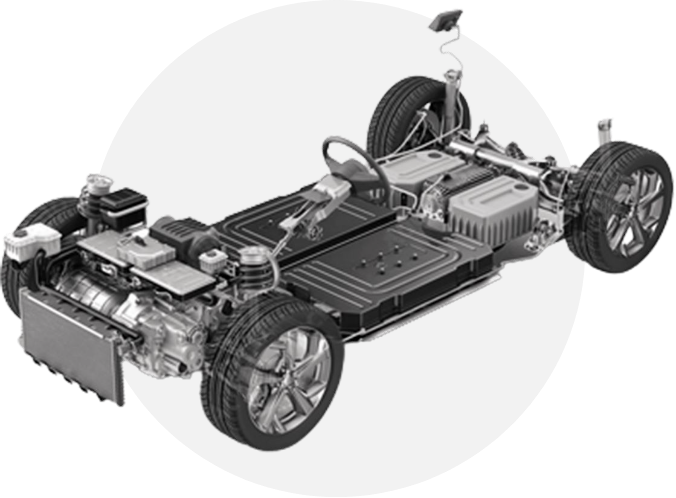

OSE GROUP offers standard and tailor-made solutions for wound products (solenoid valves, injectors, electric actuators, motors, etc.) but also manual or automated assembly lines implementing innovative solutions to ensure outstanding flexibility of installations based on collaborative robotics. The R&D unit develops innovative solutions to new issues, such as the need for modularity and flexibility of production lines and better use of data to improve line performance. Standardized modules allow a new production line to be implemented in a very short time. All these solutions (MODULAR, PROLYNK, WATCHLINE) are unique and the result of more than ten years of development.

The installations are carried out worldwide; they have a worldwide network of subsidiaries and partners, allowing them to provide after-sales service and, more generally, the perfect maintenance in the operational condition of the equipment leaving the workshop. OSE GROUP experts are at the service of customers during the product engineering phases to bring process expertise to product optimization (e.g., design of electric motors, heat exchangers, electronic modules, and electro-mechanical components).

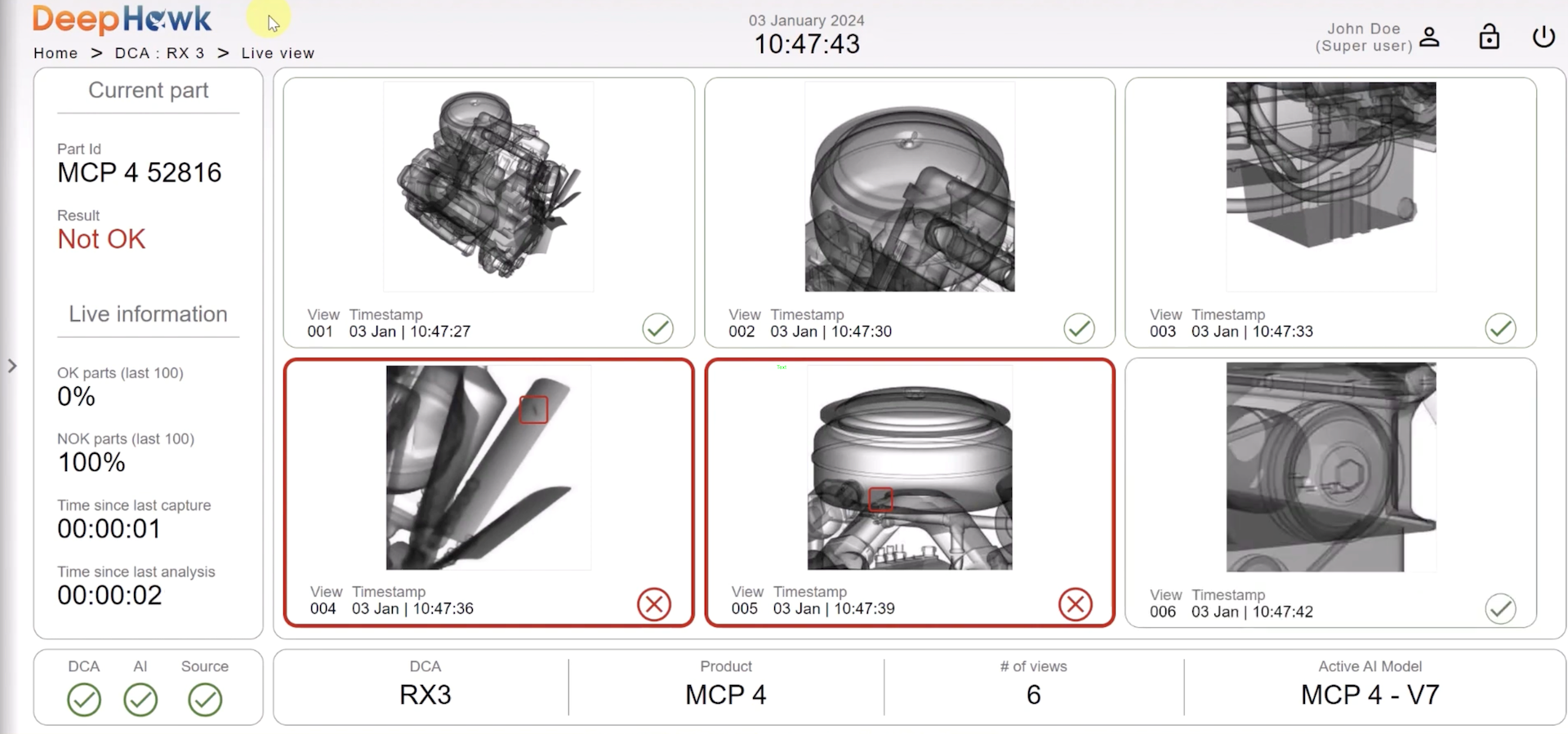

The R&D unit develops innovative solutions to new issues, such as the need for modularity and flexibility of production lines and better use of data to improve line performance. Standardized modules allow a new production line to be implemented in a very short time. All these solutions (MODULAR, PROLYNK, WATCHLINE) are unique and the result of more than ten years of development.