Hall 3.2 – Booth 100 I

#ArtificialIntelligence #MachineVision #PredictiveMaintenance #OpticalMeasurement #Innovation #Difgitalization

about us :

R&D Vision designs, manufactures and industrializes innovative solutions integrating image acquisition, optical measurement and Artificial Intelligence.

Mastering the entire optical, electronic, mechanical, Ux and AI algorithms development, our know-how covers:

• POC

• Design and manufacture of prototypes

• Industrialization and production of value-added optical systems

With Innovation, R&D, engineering and maintenance teams of major clients, we address a variety of needs: Object recognition, Defect identification, 3D, NDT, IR thermography, Highspeed Imaging, Real time, Laser metrology, Deep Learning, …

These few examples illustrate our expertise:

• Catenary predictive maintenance: systems for georeferenced measurements at the catenary level (wear, geometry, pantograph shocks, temperature, arcs, etc.) and anomaly detection (catenary equipment faults, etc.).

• Predictive maintenance of rolling stock: detection of non-conformities on trains: missing parts, loosening of nuts, leaks, 3D wear, thermal heating, etc.

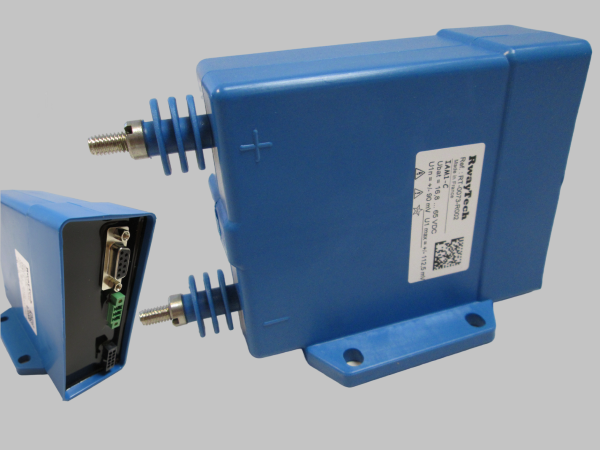

• Railway side systems: Multifunction equipment installed on the railway side for object recognition on trains (logos, etc.) and OCR.

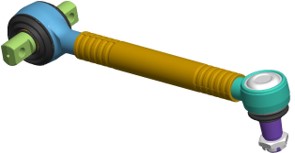

• Embedded systems on passenger trains: Laser metrology systems developed and certified to measure the 3D position of the platform in relation to the door sill to deploy the gap filler and facilitate access for wheelchairs.

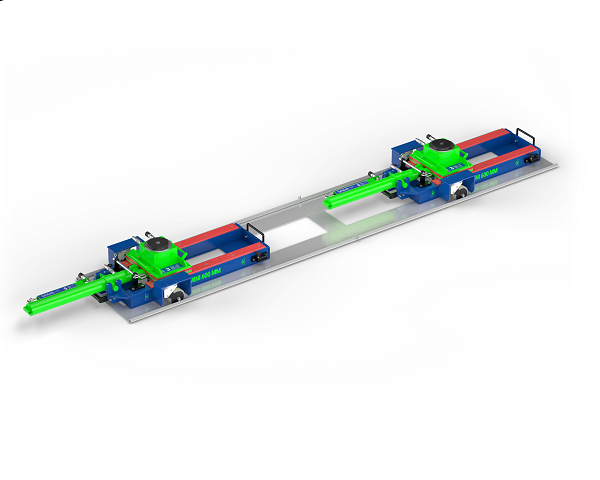

CamCat is an optical measurement truck dedicated to predictive maintenance of the catenary. Equipped with visible and thermal cameras, it is used at commercial speed to detect fault points using AI at equipment level. Alerts are reported to generate work orders and plan targeted maintenance operations.

SYRENE is a system installed at the edge of the track to detect and read the identifiers of trains. Coupled with measuring devices on the track, SYRENE has been validated up to 320km/h. The character and logo recognition AI sends the data in real time to the cloud to be consulted via a web application.

SDQ is a platform detection system. It uses lasers to measure the 3D position of the platform in relation to the train door threshold to facilitate access for wheelchairs. The lasers are coupled to a camera and an AI which reports information in real time. Custom-designed and patented, more than 2,000 lasers are mounted on regional trains.

CONTACT US

64, rue Bourdignon – 94100 SAINT MAUR DES FOSSES – France

E-mail : info@rd-vision.com

Tél. : +33 (0)1 76 62 11 50 / +33 (0)6 08 89 72 95

www.rd-vision.com