Hall 8.2 – Booth 120

#SelfLockingNuts #SafetyFastenersManufacturing #LanfrancoSlottedNuts #ReusableSelfLockingNut #LanfrancoMadeInFrance #SecurityFasteners

about us :

ENSURE RELIABILITY WITH HIGH-PERFORMANCE, VIBRATION-RESISTANT SELF-LOCKING NUTS

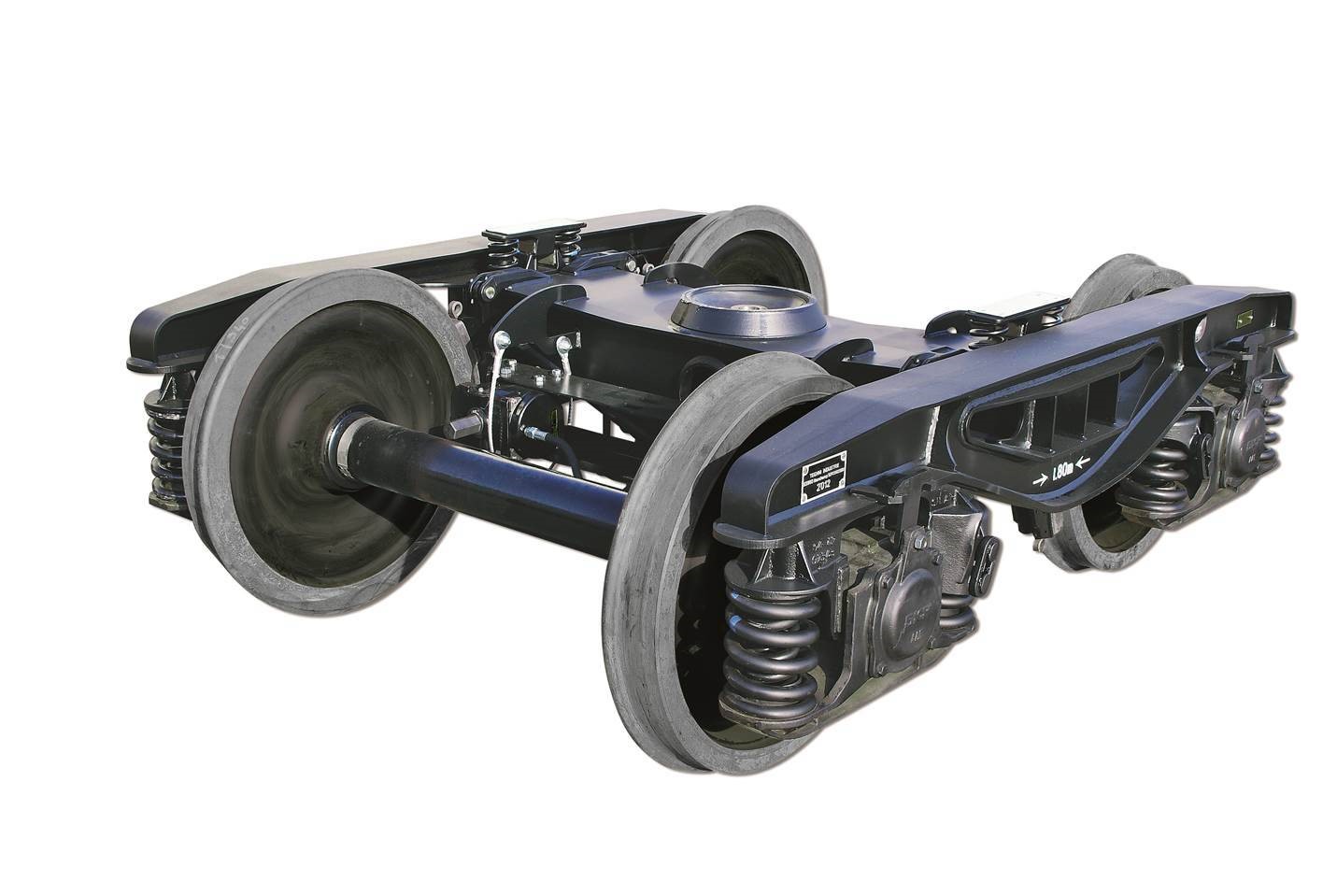

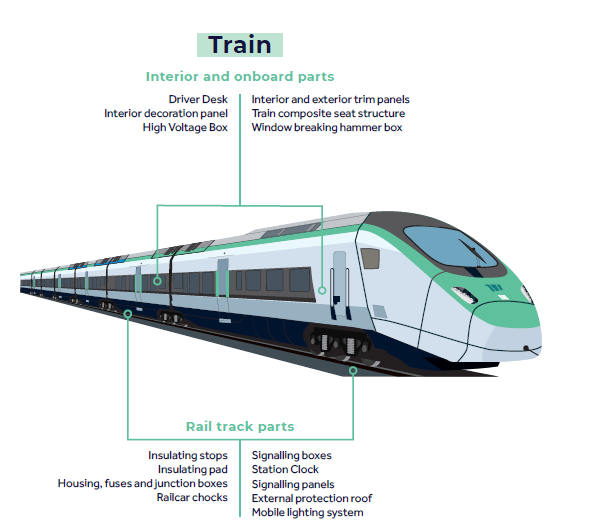

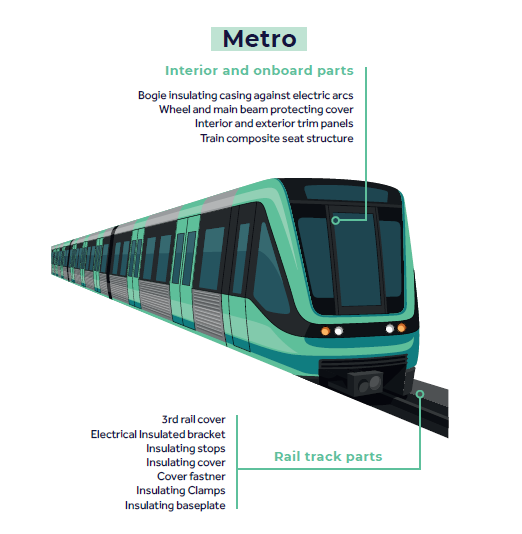

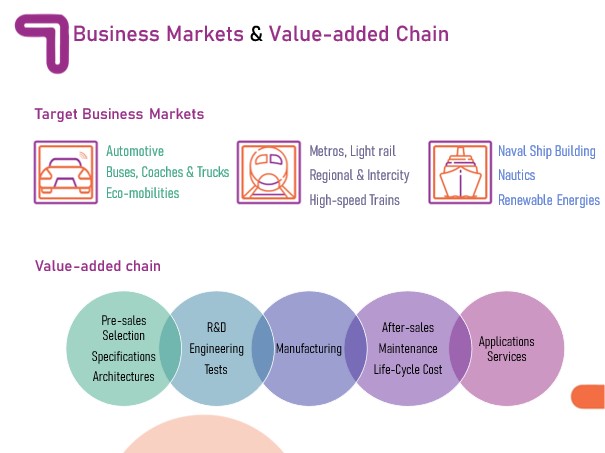

J. LANFRANCO & Cie has been manufacturing self-locking nuts for 50 years. Our safety fasteners are designed to meet any standard (European, North or South American) in the railway, mining, nuclear, aerospace and petrochemical industries.

The LANFRANCO fasteners are as diversified as they are specific, due to the wide range of applications. Our products can secure any critical bolted joint.

With our cutting-edge equipment, our company has reached the same level of expertise as private laboratories.

We have expanded our production plant to over 10,000 m2 to keep up with the increasing demand for our products.

Our machinery includes around ten robotic transfer units with the capacity to produce both small and large series. The factory also has CNC machines to produce custom parts and non-standard products.

These new production capacities enable us to respond more effectively to short production cycles, both urgent requests and specific orders with tight deadlines.

We also have greater storage capacity, which means better management and a higher quality of service.

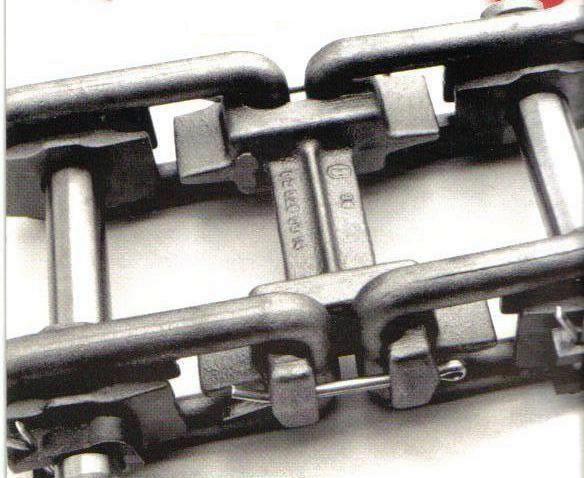

The locking device is ensured by the two slots located on the turret part of the nut.

Each slot is de-piched by a precise manufacturing process.

Once the nut is fitted on the screw, the slots are pushed back open to their original shape and grip against the thread flanks of the screw which creates the torque.

This locking technology allows a minimum of 5 installations.

The ERM nut has a free spring washer crimped on the nut to become a single piece and ensure better tension in the screw, better distribution, and continuous contact, ideal for electrical connections.

A unique all-metal piece ensuring optimal performance to corrosive and chemical substances and in temperature conditions ranging from -70° C to +500° C

The self-locking principle of the HUP nut is to crimp a nylon ring on the upper part of the nut so that when the screw is fitted, the ring is deformed by the threads, allowing the screw to be braked significantly without vibration.

Temperature resistance of the standard nylon ring: -40°C to +120°C

Temperature resistance of the brown high temperature nylon: -40°C to +230°C

OUR ECO-RESPONSIBLE COMMITMENTS :

Our environmental policy is part of both a short-term operational approach and a long-term vision, and is fully in line with J.LANFRANCO’s global strategy.

Several areas of operational control relating to our impacting environmental aspects have been defined:

Comply with environmental laws and other specifics requirements.

Evaluate and reduce as far as possible the environmental impact of all our activities. Measure the effectiveness of the actions implemented.

Raise awareness, encourage participation and train employees in environmental issues. Communicate objectives and indicators.

Evaluate the environmental approach of our suppliers and adopt the most virtuous relationship possible.

This environmental policy and the associated objectives are reviewed periodically to ensure that they remain relevant.

It is in line with J.LANFRANCO & Cie’s general guidelines and contributes to the company’s environmental commitment and performance.

CONTACT US

37 avenue de Saint-Mandé – 75012 – Paris – FRANCE

E-mail: commercial@lanfranco.fr

Tél. : +33 (0)1 40 04 92 30

www.lanfranco.fr