Hall 11.2 – Booth 270 W

#EN15085 #SheetMetal #BoilerMaking #Welding #Bending #Design

about us :

Since 1980, CETIL, a French company based in Touraine, has been providing its customers with its know-how in the processing of metal (steel, stainless steel, aluminium).

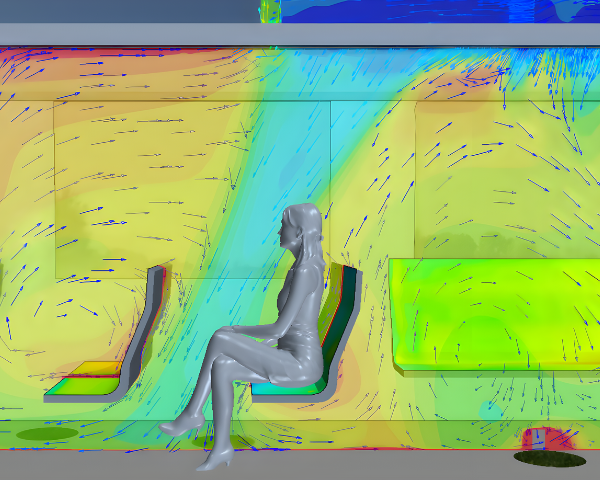

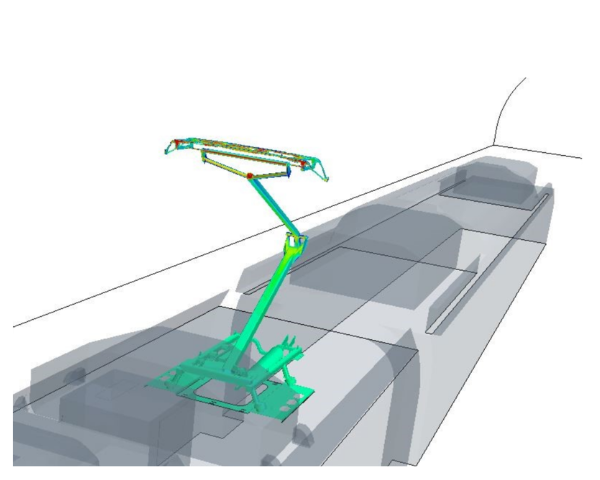

Specialised in sheet metal, boilermaking and mechanical welding, our company, employing 42 people, meets the requirements of many sectors: Rail, Aeronautics, Pharmaceutical, Medical, Nuclear, etc.

As a genuine subcontractor and technical partner, our customers enjoy the benefit of our service in their projects.

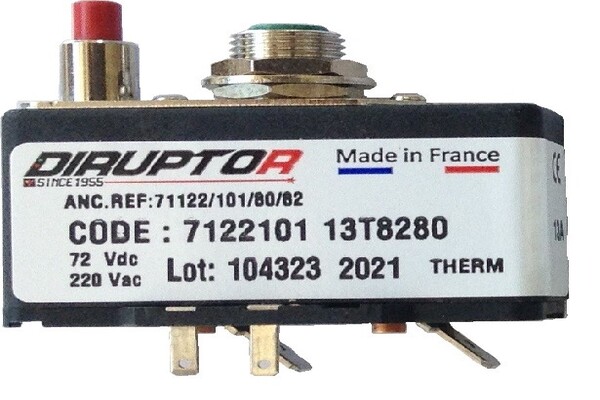

Certified ISO 9001, EN 15085 and ISO 3834, these standards commit us to providing an overall quality of our processes and delivered parts.

Much more than a subcontracting service, CETIL provides its customers with a real support package by providing the following solutions:

– Co-design / Business Expertise,

– Supply management (components, materials, etc.)

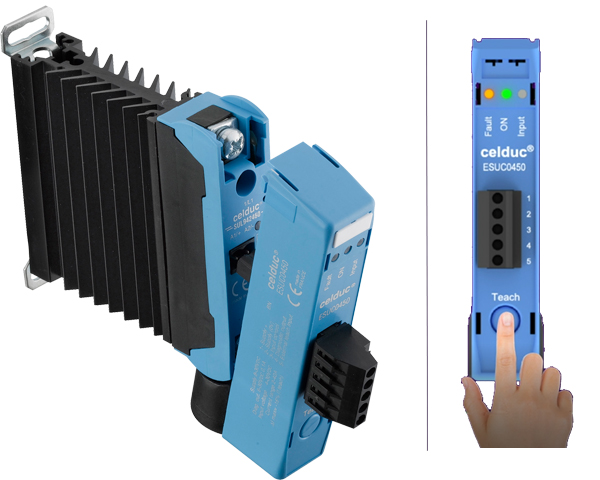

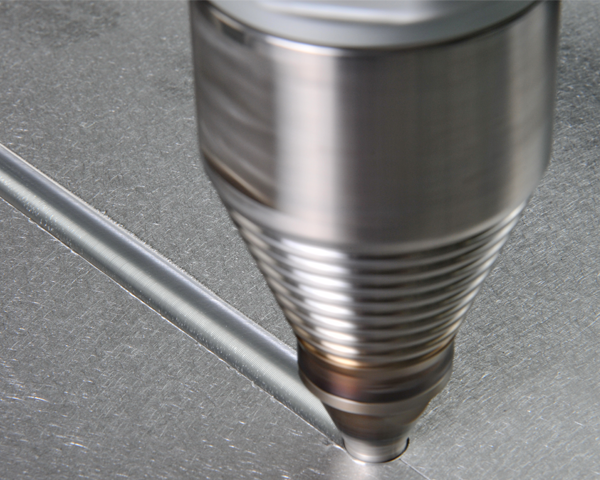

– Manufacturing (cutting, bending, welding, polishing,

surface treatment, etc.) ,

– Assembly / Pre-assembly,

– etc.

This range of services allows our customers to focus on their core business. The entire CETIL team is available to study and support your projects.

INDUSTRIAL SUB CONTRACTOR WITH MORE THAN 40 YEARS OF EXPERIENCE IN RAILWAY SECTOR

CERTIFIED : EN15085 // ISO3834 // ISO9001

4600m² FULLY DEDICATED TO OUR CUSTOMERS

STEEL – STAINLESS STEEL AND ALIMINIUM WORKED

OUR KNOW HOW : DESIGN // SHEET METAL // BOILERMAKING // WELDING // POLISHING // PAINTING // ASSEMBLY

CONTACT US

8 Allée Léonard de Vinci – 37250 MONTBAZON – France

E-mail : cetil@cetil.fr

Tél. : +33 (0)2 47 34 60 00 / +33 (0)2 47 34 60 06

www.cetil-tolerie-chaudronnerie.fr